Multifunctional particulate matter drying mechanism

A granular and multi-functional technology, applied in the direction of non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of moisture easily staying in the device, affecting normal operation, single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

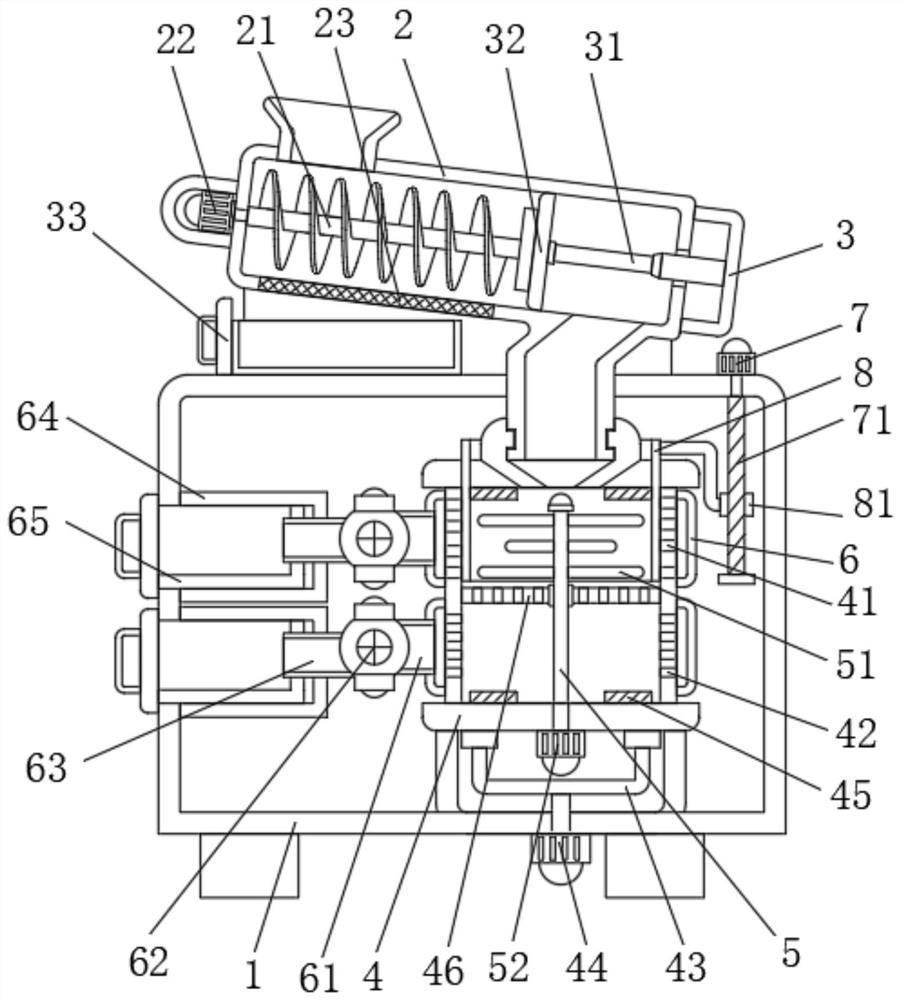

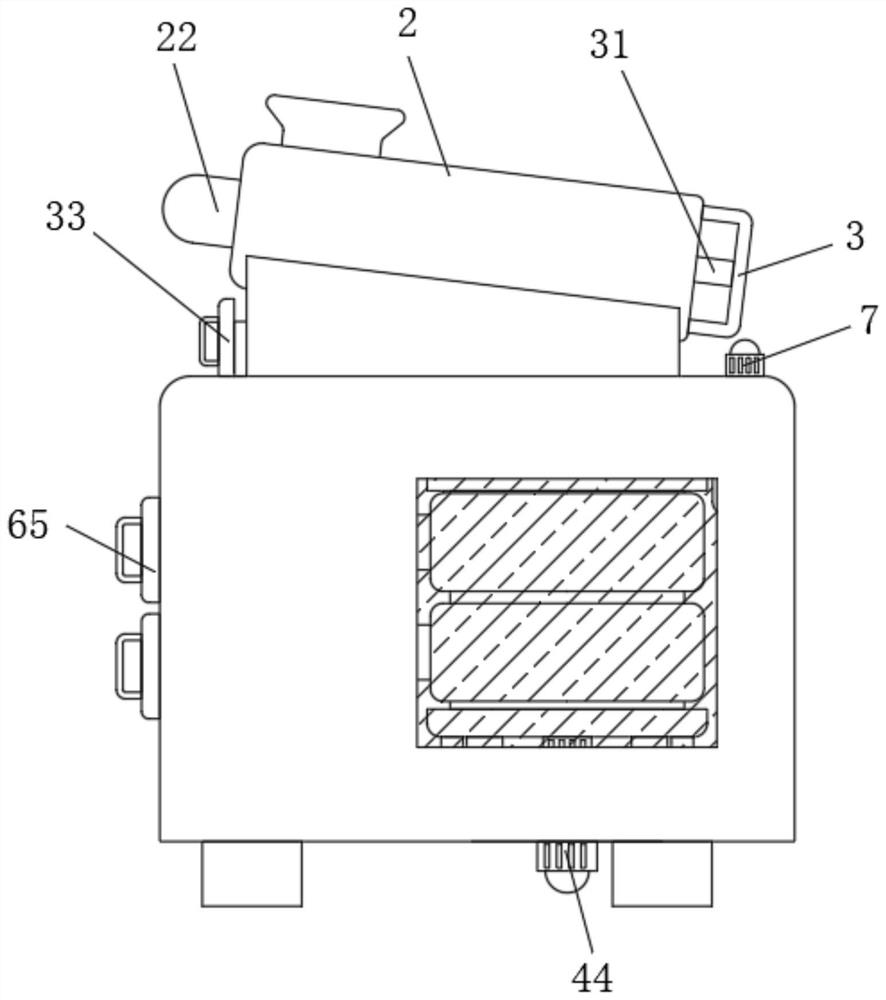

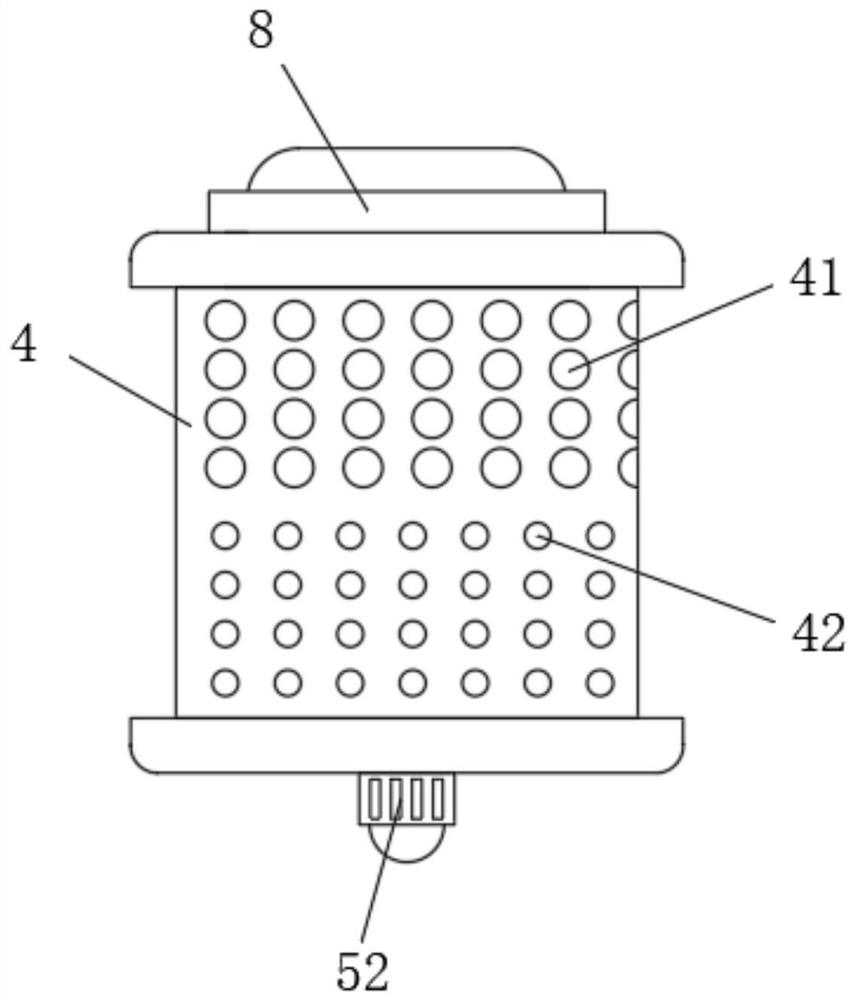

[0030] Example 1: See Figure 1-7 , the multifunctional particle drying mechanism of the present invention comprises an outer box 1, the top of the outer box 1 is fixedly connected with a feed pipe 2, the inside of the feed pipe 2 is rotatably connected with a screw feed rod 21, and the left side of the feed pipe 2 is fixedly connected There is a first motor 22, the bottom of the feeding pipe 2 is fixedly connected with a filter screen 23, the right side of the feeding pipe 2 is fixedly connected with a connecting plate 3, and the left side of the connecting plate 3 is fixedly connected with an electric telescopic rod 31, and the electric telescopic rod The left side of 31 is fixedly connected with a baffle 32, and the inside of the outer box 1 is rotatably connected with a drying barrel 4 at a position close to the right side, and a first filter hole 41 is ring-shaped on the surface of the drying barrel 4 near the top. 4 surface and the position near the bottom are provided w...

Embodiment 2

[0039] Example 2: See Figure 8 , a vacuum cleaner 9 is fixedly connected to the top of the outer box 1 and close to the left side, and the dust inlet pipe provided on the vacuum cleaner 9 is fixedly connected to the bottom of the feeding pipe 2 and corresponds to the position of the filter screen 23. The particulate matter in the pipe 2 has less water inclusions, but when dust and impurities are more mixed, the dust mixed in the particulate matter poured into the material pipe 2 can be sucked through the filter screen 23 by using the vacuum cleaner 9 and the filter screen 23, so as to avoid the inside of the particulate matter. The inclusion of dust affects subsequent processing operations.

[0040] When using the present invention, first start the electric telescopic rod 31, use the electric telescopic rod 31 to drive the baffle plate 32 to move to the left in the feeding pipe 2, then pour the particles that need to be dried into the feeding pipe 2, and start simultaneously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com