Protection device and method for damage and fracture of gas pipeline

A technology for gas pipelines and protective devices, which is applied to pipeline systems, pipes, pipe components, etc., can solve problems such as damage and rupture of gas pipelines, achieve rapid and tight connection, tight inflatable fit, and prevent interruption of gas transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

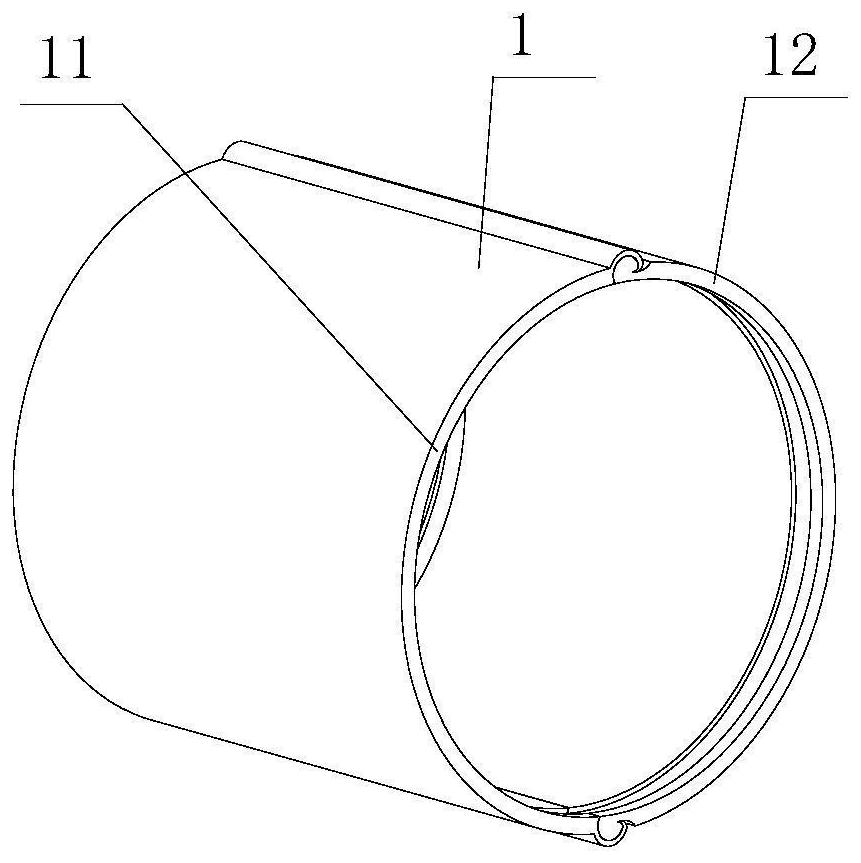

[0038] see figure 1 The protective device for gas pipeline damage and rupture provided in this embodiment includes a cylindrical main body 1; a sealing member is arranged on the inner wall of the main body 1 .

[0039] In this example, see figure 1 and Figure 5 , the main body 1 is a cylindrical structure, the main body 1 includes a left pipe 11 and a right pipe 12 connected to the left pipe 11 through a clamping part; the left pipe 11 and the right pipe 12 are both semi-cylindrical structures with the same structure; the left pipe 11 and the The right pipe 12 forms the cylindrical body 1 .

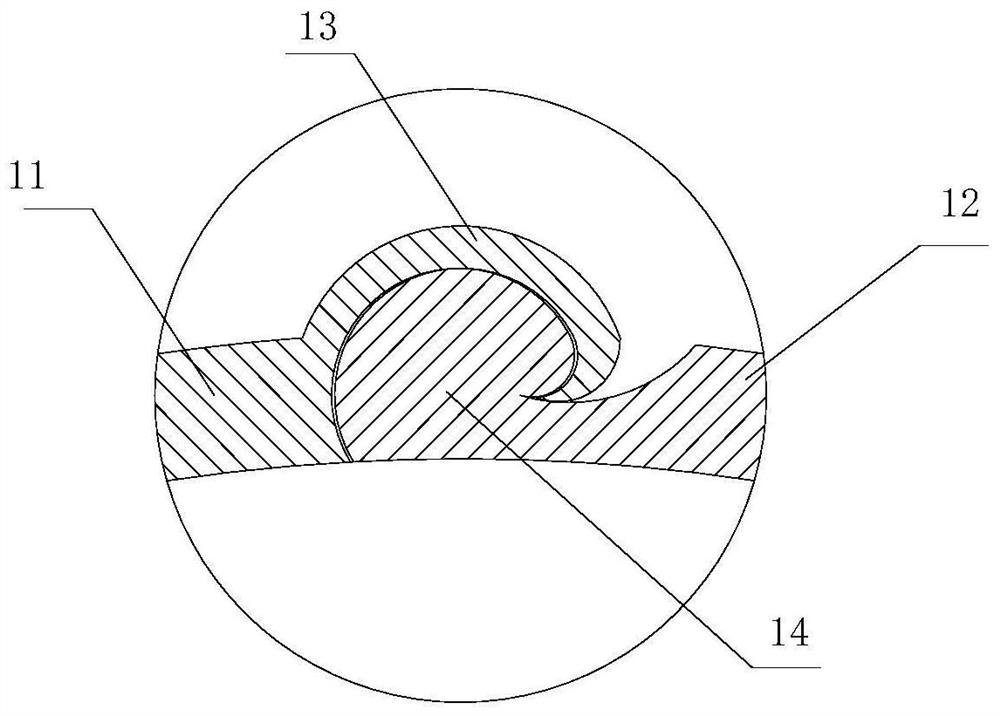

[0040] see figure 2 , The clamping part includes a return groove 13 and a protrusion 14; the return groove 13 is placed at the end of the left pipe 11; the protrusion 14 is placed at the end of the right pipe 12; the protrusion 14 is snapped into the return groove 13. The return groove 13 is an arc groove, and the protrusion 14 is a housing-shaped protrusion matched with the return ...

Embodiment 2

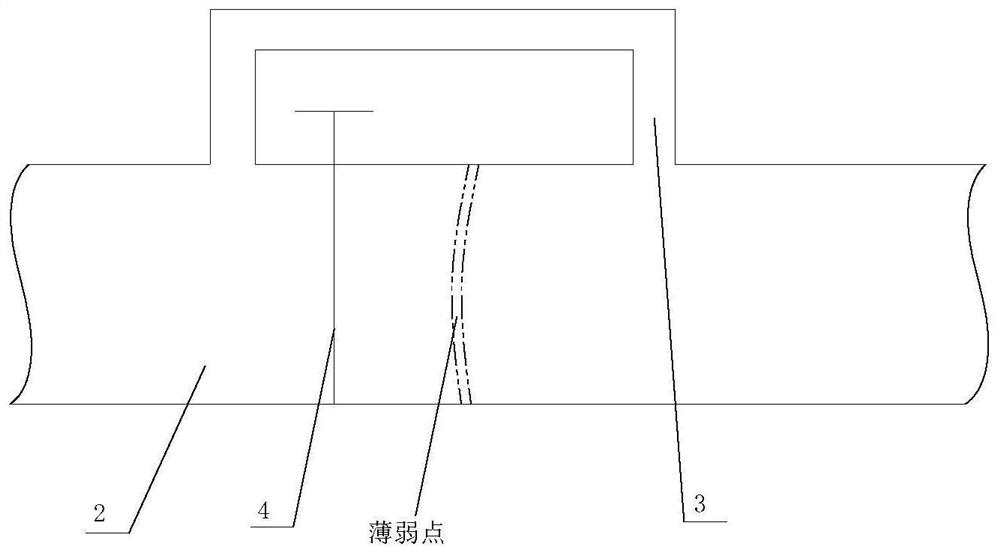

[0044] see image 3 , in this embodiment, the protective device for damage and rupture of the gas pipeline further includes a side pipe 3; the side pipe 3 is arranged in parallel with the main body 1. Specifically, both ends of the side pipe 3 communicate with the gas pipeline 2 to be protected respectively.

[0045] In this embodiment, the protection device for damage and rupture of the gas pipeline also includes a valve 4; the valve 4 is placed at the front end of the main body 1; specifically, the valve 4 is placed on the gas pipeline 2 to be protected.

[0046]In this embodiment, the valve 4 is placed at the front end of the weak point of the gas transmission pipeline 2 to be protected; the side pipe 3 is a U-shaped pipe, and one end of the side pipe 3 is placed on the valve 4 and communicated with the gas transmission pipeline 2 to be protected; the other end of the side pipe 3 Placed at the rear end of the weak point of the gas pipeline 2 to be protected and communicate...

Embodiment 3

[0048] The protection method for gas pipeline damage and rupture provided by this embodiment includes the following steps:

[0049] 1) Determine the weak point where damage and rupture occur on the gas pipeline 2 to be transported;

[0050] Specifically, 1.1) collect relevant background, technical conditions and geological conditions when the buried gas pipeline 2 is damaged during the relevant oil and gas transportation, and form a complete database;

[0051] 1.2) Predict the possible positions of weak points by means of probability statistics, find out the areas prone to oil leakage of the gas pipeline 2, and find out the geological laws existing in the possible oil leakage places;

[0052] 1.3) According to the geological data, it is judged that the section with an oil leakage probability exceeding 95% on the gas pipeline 2 is a weak point;

[0053] 2) Put the main body 1 on the gas pipeline 2 at the weak point, and seal the inner wall of the main body 1 and the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com