A kind of multi-layer structure ceramsite sound-absorbing board for sound barrier and its preparation method

A multi-layer structure, sound-absorbing board technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve problems such as insufficient mechanical and acoustic properties, and achieve cost reduction, weight reduction, and reduction of adhesive dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the above-mentioned multi-layer structure ceramsite sound-absorbing board for sound barrier comprises the following steps:

[0049] (1) Prepare each layer of ceramsite sound-absorbing panels separately: After fully mixing the ceramsite aggregate and cementitious material of each layer of ceramsite sound-absorbing panels in proportion, press and cast them into panels;

[0050] (2) After the curing and demoulding of each layer of ceramsite sound-absorbing panels, the multi-layer structure ceramsite sound-absorbing panels are bonded through cementitious materials.

[0051] Another preparation method of the above-mentioned multi-layer structure ceramsite sound-absorbing board for sound barriers includes the following steps:

[0052] (1) Fully mix the ceramsite aggregate and cementitious material of each layer of ceramsite sound-absorbing panels in proportion;

[0053] (2) Lay each layer in turn and press it into a multi-layer structure ceramsite s...

Embodiment 1

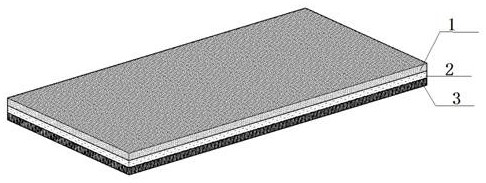

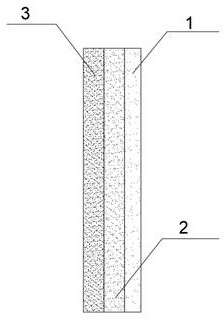

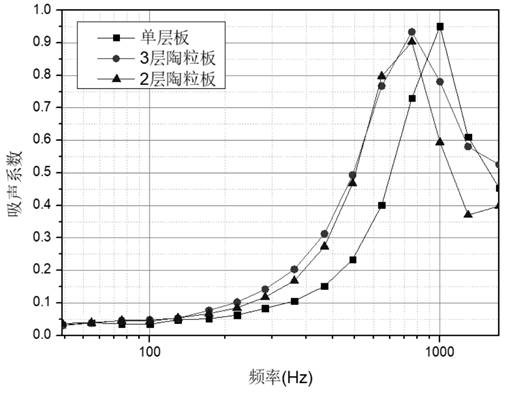

[0056] There are 3 layers of multi-layer structure ceramsite sound-absorbing panels, with a total thickness of 70mm. From the outside to the inside (the sound source side is the inside), the order is: No. 1 ceramsite board (particle size5mm), thickness 20mm. Specific as figure 1 with figure 2 shown.

[0057] The proportion of each component in No. 1 ceramsite board is: ceramsite accounts for 88%, Portland cement accounts for 9% (water-cement ratio 0.8:1), admixtures (fly ash, polycarboxylate reducing Water agent, air-entraining agent, fiber, etc.) accounted for 3%.

[0058] The proportion of each component in the No. 2 ceramsite board is: ceramsite accounts for 85%, Portland cement accounts for 12% (water-cement ratio 1:1), admixtures (fly ash, polycarboxylate Water agent, air-entraining agent, fiber, etc.) accounted for 3%.

[0059] The proportion of each component in No. 3 ceramsite board is: ceramsite accounts for 80%, Portland cement accounts for 17% (water-cement ra...

Embodiment 2

[0062] There are 3 layers of multi-layer structure ceramsite sound-absorbing panels, with a total thickness of 60mm. From the outside to the inside (the sound source side is the inside), the order is: No. 1 ceramsite board (particle size 5mm), thickness 30mm; No. 2 ceramsite board (particle size) diameter 2-5mm), thickness 20mm.

[0063] The proportion of each component in No. 1 ceramsite board is: ceramsite accounts for 88%, Portland cement accounts for 9% (water-cement ratio 0.8:1), admixtures (fly ash, polycarboxylate reducing Water agent, air-entraining agent, fiber, etc.) accounted for 3%.

[0064] The proportion of each component in No. 3 ceramsite board is: ceramsite accounts for 80%, Portland cement accounts for 17% (water-cement ratio 1:1), admixtures (fly ash, polycarboxylate Water agent, air-entraining agent, fiber, etc.) accounted for 3%.

[0065] The proportion of each component in the No. 2 ceramsite board is: ceramsite accounts for 85%, Portland cement accoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com