A kind of concrete preparation method

A concrete and aggregate technology, applied in clay preparation devices, chemical instruments and methods, unloading devices, etc., can solve the problems of sand and gravel material deposition, poor homogeneity, low efficiency, etc., to improve quality and efficiency, improve mixing effect, the effect of eliminating the stirring dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0035] The concrete preparation method of the present embodiment specifically comprises the following steps:

[0036] Step S1, aggregate screening. The aggregates transported to the concrete preparation site by transport vehicles are screened to obtain aggregates of suitable size.

[0037] Step S2, weighing the raw materials. According to the mixing ratio, the aggregate, cement, water, admixture solution and admixture material are respectively weighed and the required usage amount is obtained.

[0038] In step S3, the raw materials are put into the stirring device, and the materials are started to be stirred to prepare concrete.

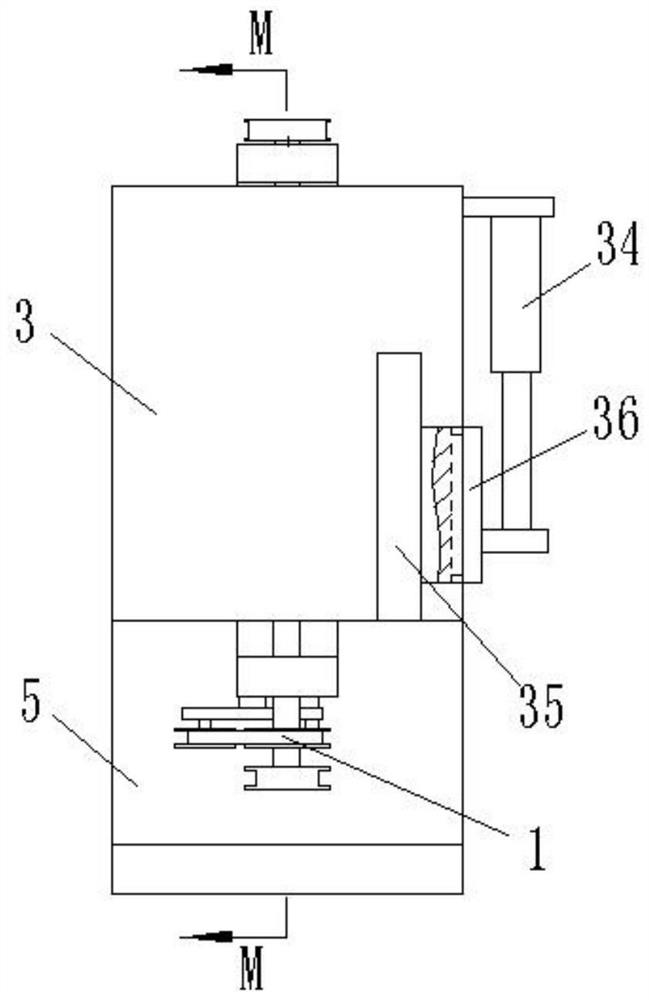

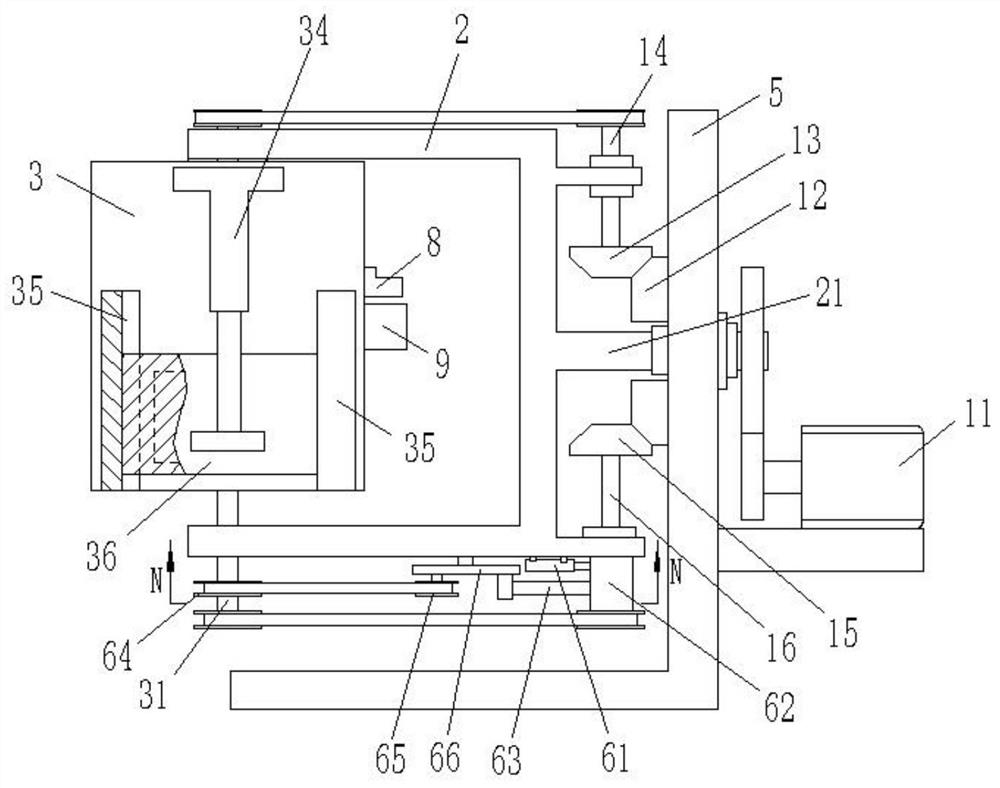

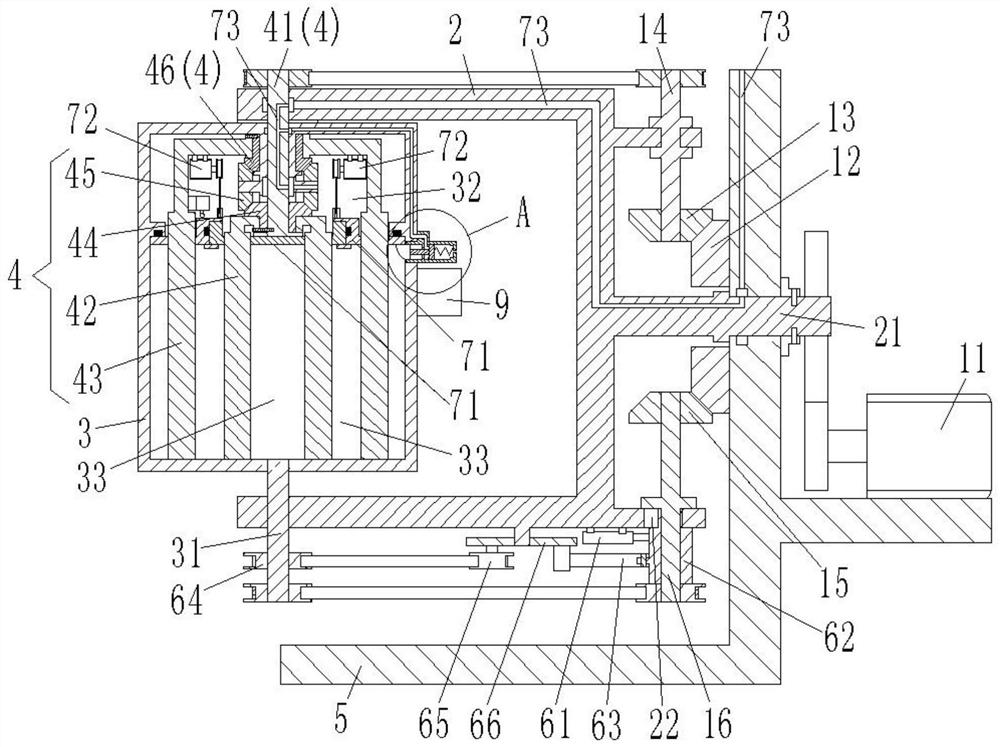

[0039] combine Figure 1 to Figure 3As shown, the material stirring device used in step S3 of this embodiment includes a driving unit 1 , a turning frame 2 , a stirring bin 3 and a stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com