Sectional transportation and on-site butt joint process for portal frame of tire crane

A tire crane and gantry technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to ensure the smooth arrival of parts to the user's yard, and the transportation of parts with large sizes, so as to ensure the accuracy of docking and Quality, reduce prestress, improve the effect of subsequent docking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

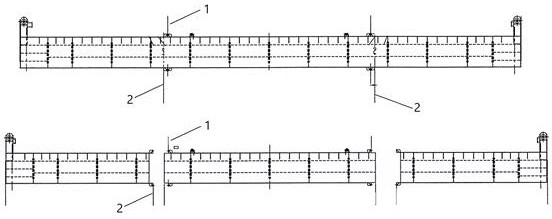

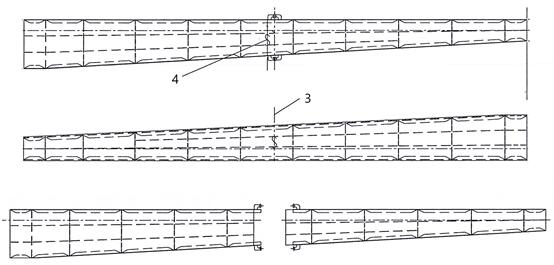

[0028] Such as Figure 1 to Figure 2 Shown is a tire crane gantry segmented delivery and on-site docking process, the gantry structure includes a main beam and outriggers.

[0029] The segmental delivery process and docking process of the main girder are as follows:

[0030] The main girder needs to be cut into three sections. Confirm the section on the main beam, that is, the section line 1 of the main beam face plate and the section line 2 of the web plate of the main beam, and the section line 1 of the face plate of the main beam and the section line of the web plate of the main beam Stagger 200mm between lines 2;

[0031] Assemble the welded flange plate at section line 1 of the main beam face plate, and tighten the welded flange plate with process bolts to facilitate rapid and smooth splicing in the later stage;

[0032] Use a semi-automatic cutting machine to cut at the segment line. After cutting, remove the process bolts and keep them on the flange plate on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com