Repairing device applied after removal of bacterial plaques on surface of material in cabin of space station and application method

A space station and plaque technology, applied to the device and coating of the surface coating liquid, can solve the problems of cumbersome operation process and inconvenient operation for astronauts, and achieve simple operation, small and light equipment, and prevent liquid backflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0068] This embodiment provides a method for using the repair device after the plaque removal on the material surface of the space station cabin in Embodiment 1, including the following steps:

[0069] (1) Equipment assembly;

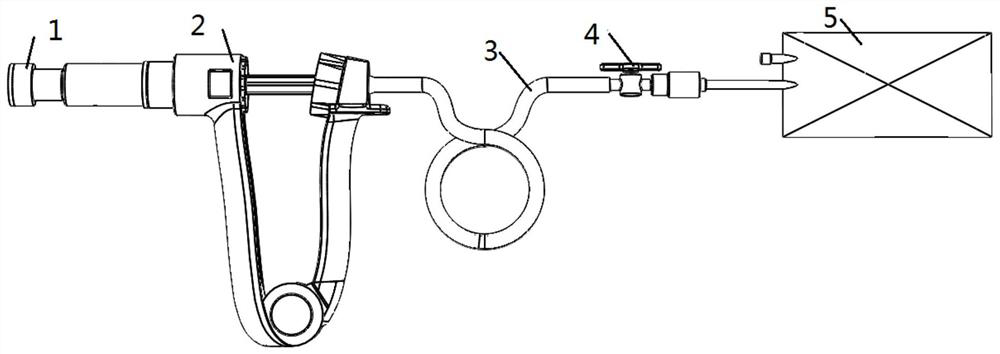

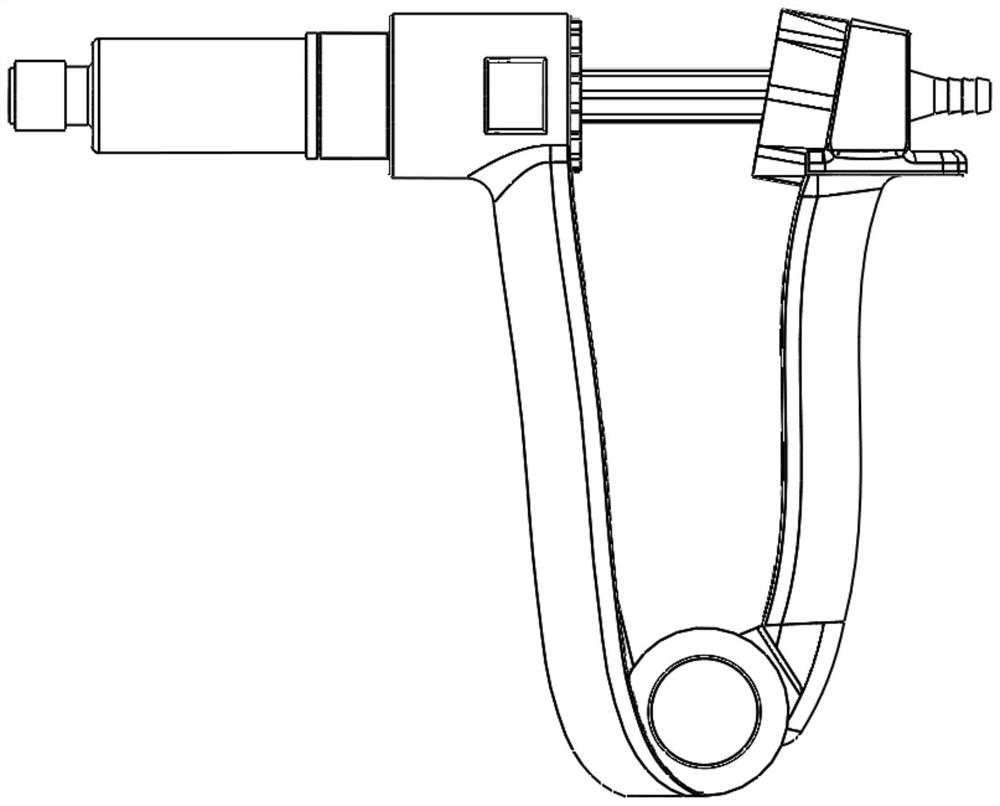

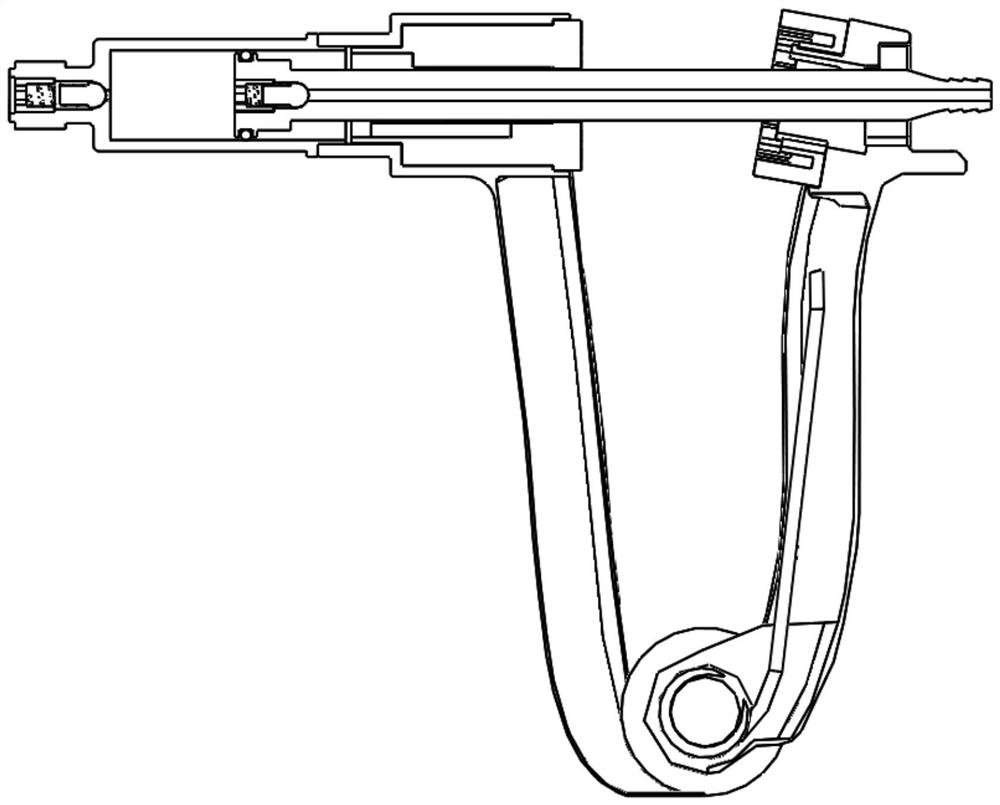

[0070] Select the brush head 1 according to the required coating area and position of the material surface in the space station cabin, connect the brush head 1 to the front end of the sampler 2 through threads, connect the rear end of the sampler 2 to one end of the pipeline 3, and the pipeline 3 The other end is connected to one end of the valve 4 to keep the valve 4 closed, and the other side of the valve 4 is connected to the liquid outlet of the liquid storage bag 5 through a Luer interface. The water-based antibacterial and antifungal agent is housed in the liquid storage bag 5. At this time, Keep valve 4 closed, and injector 2 is at the maximum injection volume;

[0071] (2) Exhaust the air;

[0072] Continuously press the movable handle 31 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com