A Drainage Method for Coalbed Gas Horizontal Wells with Power Expansion, Pressure Relief and Permeability Enhancement

A technology for horizontal wells and coalbed methane, which is applied in drilling equipment and methods, directional drilling, and fluid extraction, etc., can solve the problems of high cost, large amount of underground coal mining, hidden danger of underground gas safety, etc., and achieves improved productivity and high efficiency. The effect of rapid extraction and elimination of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

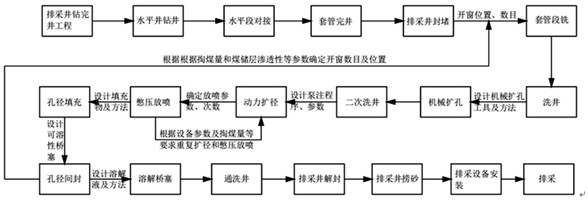

Method used

Image

Examples

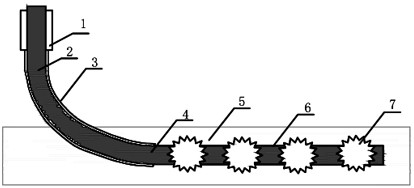

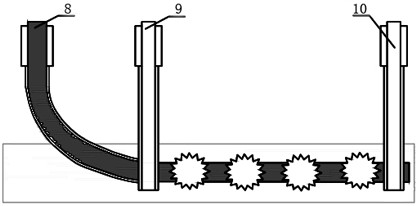

Embodiment Construction

[0044] 1) Drilling and completion of drainage wells:

[0045]Optimal drainage method: According to the inclination angle of the coal seam and the specific conditions of the ground, three drainage methods are selected: engineering well drainage, near-end butt joint well drainage, and far-end butt joint well drainage. When the inclination angle of the target coal seam is large, the target coal seam is uphill along the horizontal section of the horizontal well, and when the engineering well drills the coal seam at a relatively low end, the engineering well can be selected for drainage or the near-end docking well for drainage; The direction of the horizontal section of the horizontal well is downhill, and when the drainage well drills a relatively low-end coal seam, the remote butt joint well can be used for drainage.

[0046] Borehole structure of the drainage well: the diameter of the first opening is 311mm, drilled to 10m below the bedrock, the 244.5mm technical casing is run ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com