A kind of knitting method and knitted fabric of fully formed saddle shoulder collar structure

A full-molding, saddle technology, applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of insufficient roundness of the collar, easy to form bulge, affecting the appearance and quality of clothing, etc., to improve the quality and wearing comfort. , The effect of improving design concept and broad development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

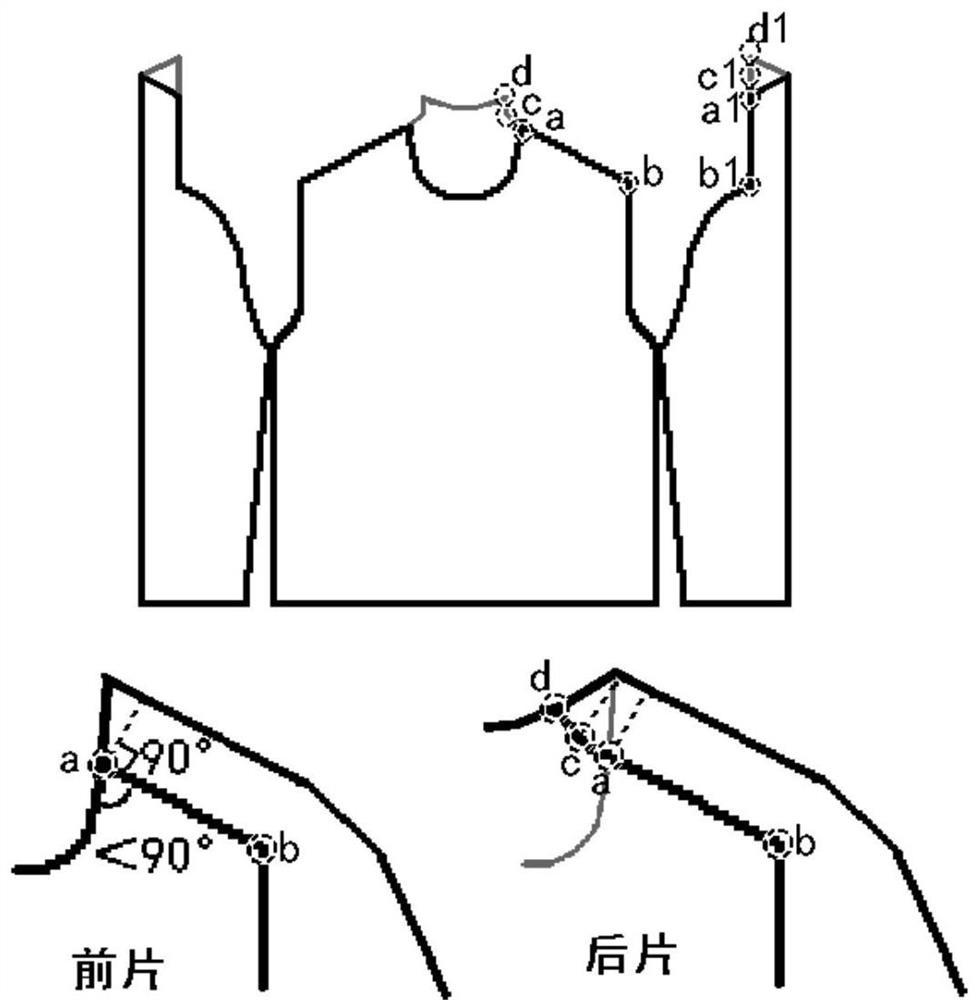

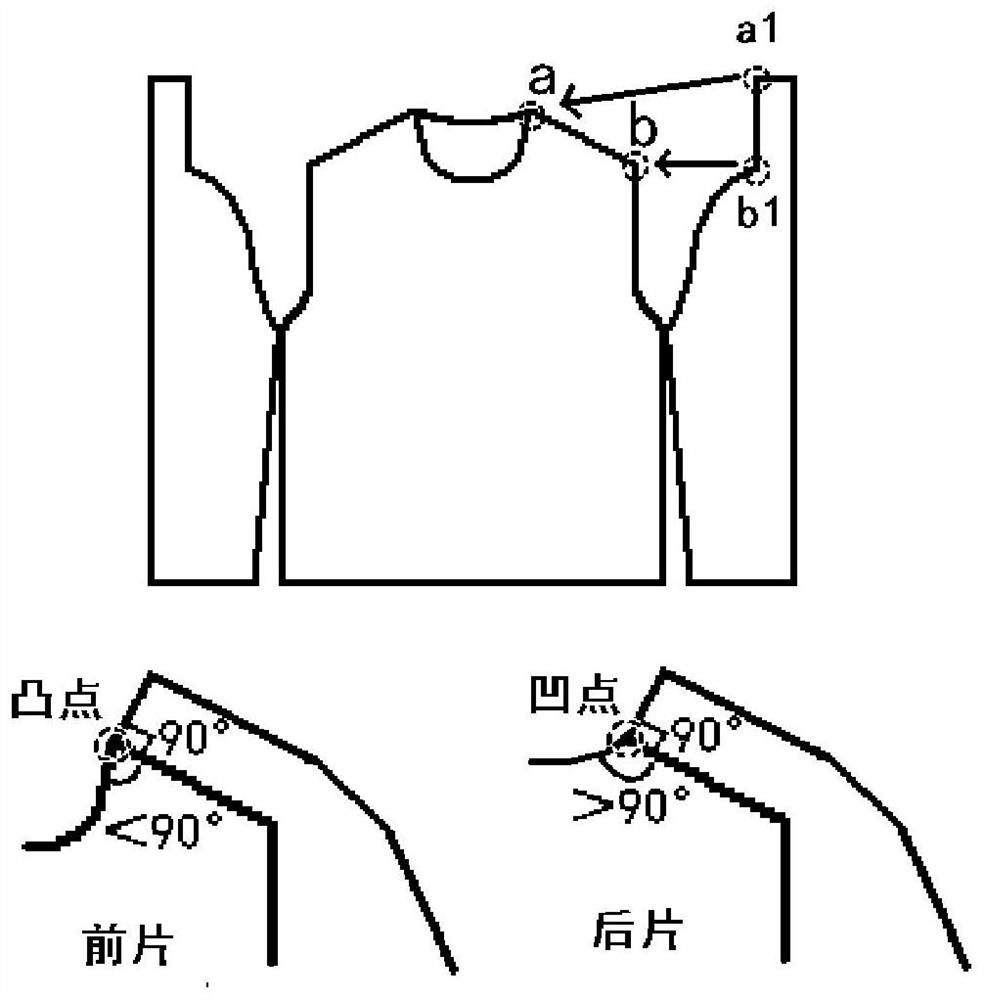

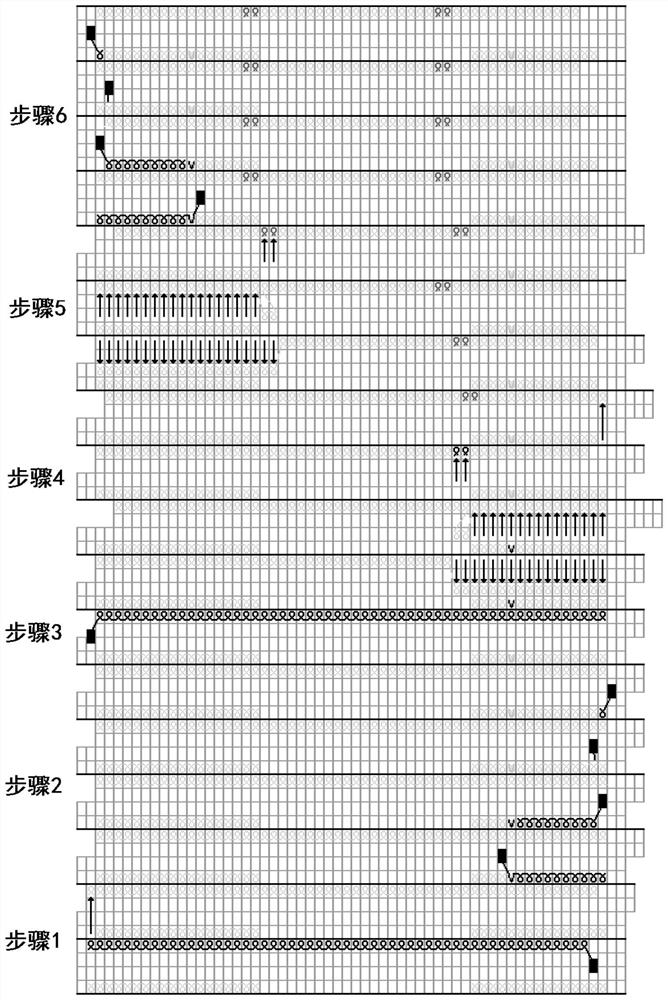

[0020] A method of knitting a fully formed saddle shoulder collar structure, using a flat knitting machine with a pair or more than one pair of needle beds extending in the left and right directions and facing each other in the front and rear directions, such as figure 1 As shown, on the basis of the traditional weaving to form the saddle shoulder, specifically, on the basis of the structure of the traditional saddle shoulder b-a, the front part of the saddle shoulder is partially knitted (a-c part) to increase the front of the saddle shoulder The angle of the piece and the angle of the collar are complementary to 180°, so that the front collar is smooth; at the same time, the back piece continues to knit the saddle part and narrow the stitches, and then knits the back collar part to form the back piece of saddle shoulder knitting (c-d part), the saddle shoulder weaving of the back piece adopts the method of local weaving with spade needle to correct the difference of the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com