Temperature control method of mesh belt furnace

A temperature control method and technology of mesh belt furnace, which are applied in the direction of heat treatment process control, furnace, heat treatment furnace, etc., can solve the problems of adverse effects of metal processing, long recovery time, and large temperature fluctuation of furnace body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

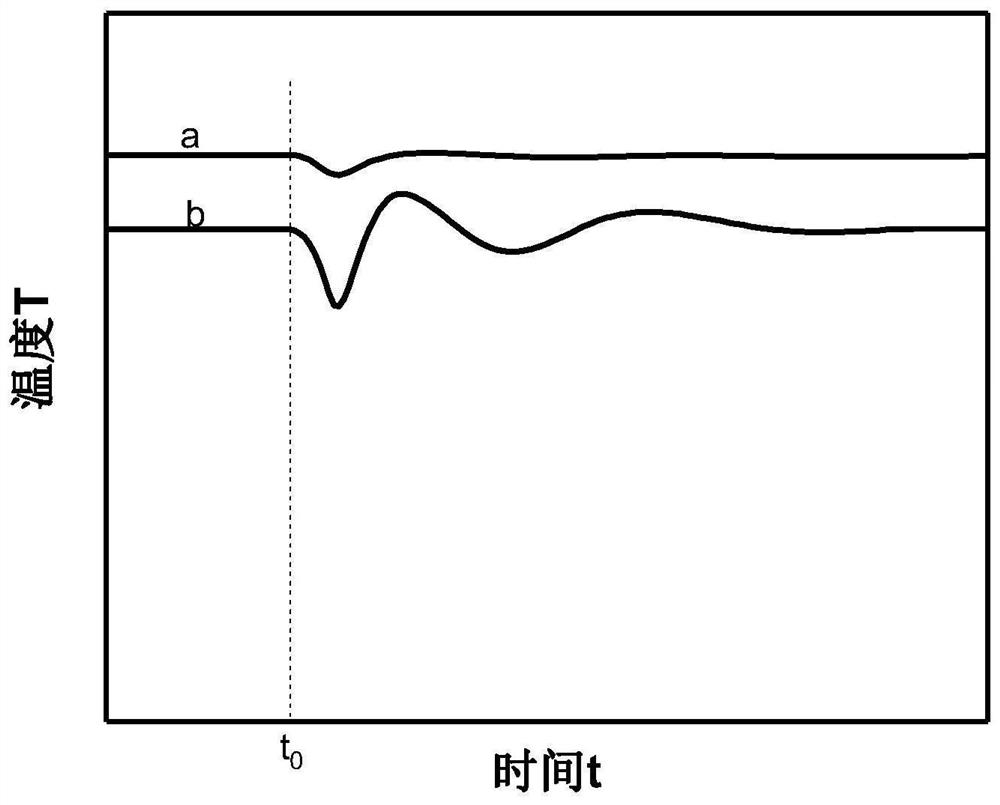

[0023] A temperature control method for a mesh belt furnace, according to the set target temperature T 0 , through the following calculations, the power of the burner is adjusted in real time, as follows.

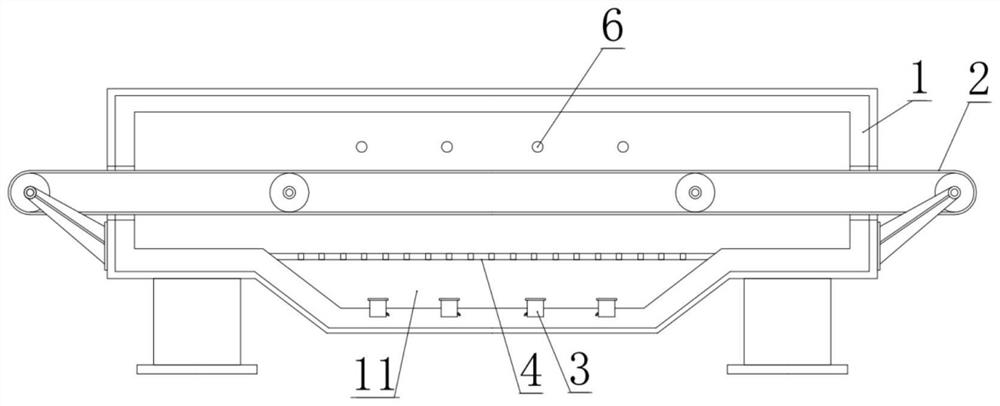

[0024] In the cooling state of the furnace body, adjust the power of the burner to k·W max , record the change of furnace temperature T with time t, and obtain the T-t curve; Wherein, the T value is to need to control the temperature that the temperature sensor 6 in the space range that reaches target temperature takes the average to obtain; k is a constant, at 0.05 ~0.08 range, W max is the maximum total power of the burner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com