A fireproof and anti-condensation material and preparation method thereof

An anti-condensation and raw material technology, applied in the direction of fire-proof coatings, anti-fouling/underwater coatings, paints containing biocides, etc., can solve the problems of moisture-proof, poor sealing and anti-condensation effects, and difficult sealing of wires and wires , Corrosion of the cable, etc., to prevent moisture from entering the equipment, excellent fire resistance, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

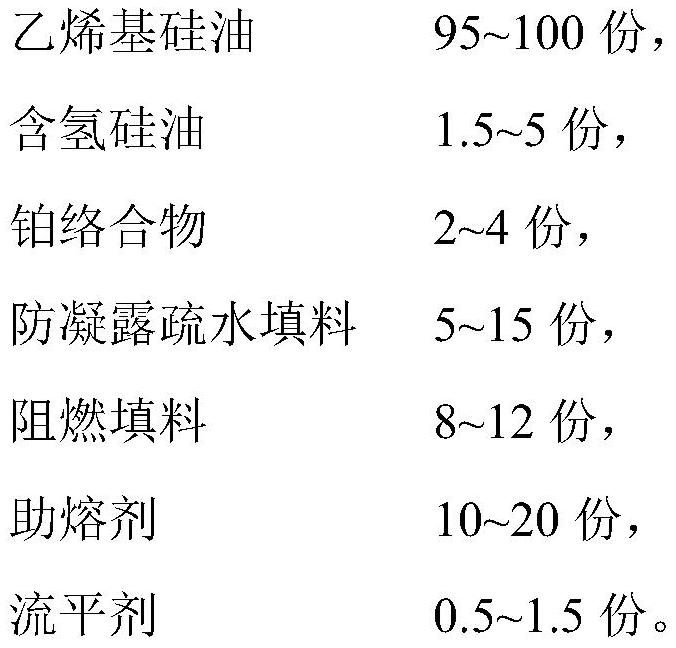

Method used

Image

Examples

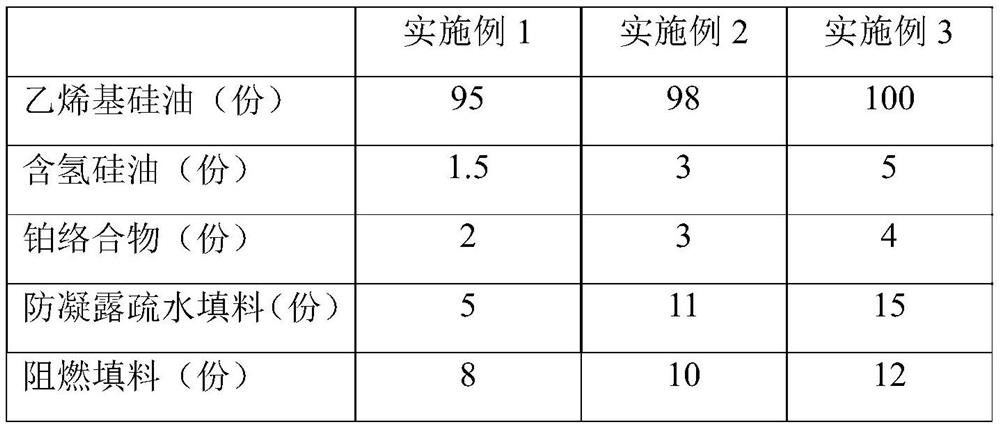

Embodiment 1

[0036] The preparation method of the fire prevention anti-condensation material in the present embodiment comprises the following steps:

[0037] (1) Add ethyl orthosilicate, methyltriethoxysilane, ethanol and water into the stirring device at a molar ratio of 1:0.5:18:4, adjust the pH to 5 with hydrochloric acid, and heat to 65°C, Hydrolyze for 80 minutes under stirring; then add ammonia water to adjust the pH to 8, continue stirring for 40 minutes, and then stand still for 10 minutes to obtain silica gel.

[0038] (2) Put the silica gel into a mixed solution of ethyl orthosilicate and ethanol (the volume ratio of ethyl orthosilicate and ethanol is 1:0.8), heat to 40°C, age for 40 hours, and dry. An anti-condensation hydrophobic filler is obtained.

[0039] (3) Ball mill the glass powder with a melting point of 400°C for 40 minutes, and then add a silane coupling agent (the mass ratio of the silane coupling agent to the low-temperature glass powder is 1:80) to prepare a flux...

Embodiment 2

[0045] The preparation method of the fire prevention anti-condensation material in the present embodiment comprises the following steps:

[0046](1) Add ethyl orthosilicate, methyltriethoxysilane, ethanol and water into the stirring device at a molar ratio of 1:0.6:19:5, adjust the pH to 5.5 with hydrochloric acid, and heat to 68°C, Hydrolyze for 70 minutes under stirring; then add ammonia water to adjust the pH to 8.2, continue stirring for 45 minutes, and then let stand for 20 minutes to obtain silica gel.

[0047] (2) Put the silica gel into the mixed solution of ethyl orthosilicate and ethanol (the volume ratio of ethyl orthosilicate and ethanol is 1:0.9), heat to 43°C, age for 35 hours, and dry. An anti-condensation hydrophobic filler is obtained.

[0048] (3) Ball mill the glass powder with a melting point of 400°C for 55 minutes, and then add a silane coupling agent (the mass ratio of the silane coupling agent to the low-temperature glass powder is 1:85) to prepare a f...

Embodiment 3

[0054] The preparation method of the fire prevention anti-condensation material in the present embodiment comprises the following steps:

[0055] (1) Add ethyl orthosilicate, methyltriethoxysilane, ethanol and water into the stirring device at a molar ratio of 1:0.7:20:6, adjust the pH to 6 with hydrochloric acid, and heat to 70°C, Hydrolyze for 60 minutes under stirring; then add ammonia water to adjust the pH to 8.5, continue stirring for 50 minutes, and then stand still for 30 minutes to obtain silica gel.

[0056] (2) Put the silica gel into a mixed solution of ethyl orthosilicate and ethanol (the volume ratio of ethyl orthosilicate and ethanol is 1:1.1), heat to 45°C, age for 30 hours, and dry. An anti-condensation hydrophobic filler is obtained.

[0057] (3) Ball mill the glass powder with a melting point of 400°C for 70 minutes, and then add a silane coupling agent (the mass ratio of the silane coupling agent to the low-temperature glass powder is 1:90) to prepare a fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com