Concrete-faced rockfill dam concrete crack inhibitor and preparation method thereof

A technology for concrete and face dams, applied in the field of material science and engineering, can solve the problems of insufficient crack resistance of face concrete, high requirements of concrete crack resistance, complex stress conditions of face dams, etc., so as to reduce concrete cracks and improve crack resistance. ability, the effect of reducing the susceptibility to plastic shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

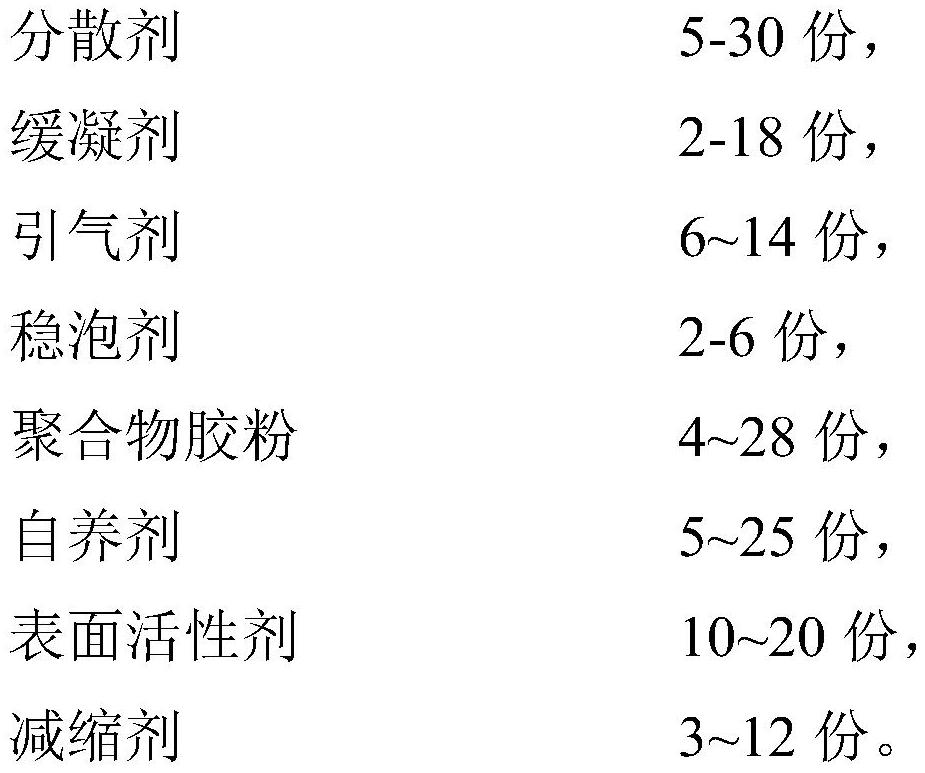

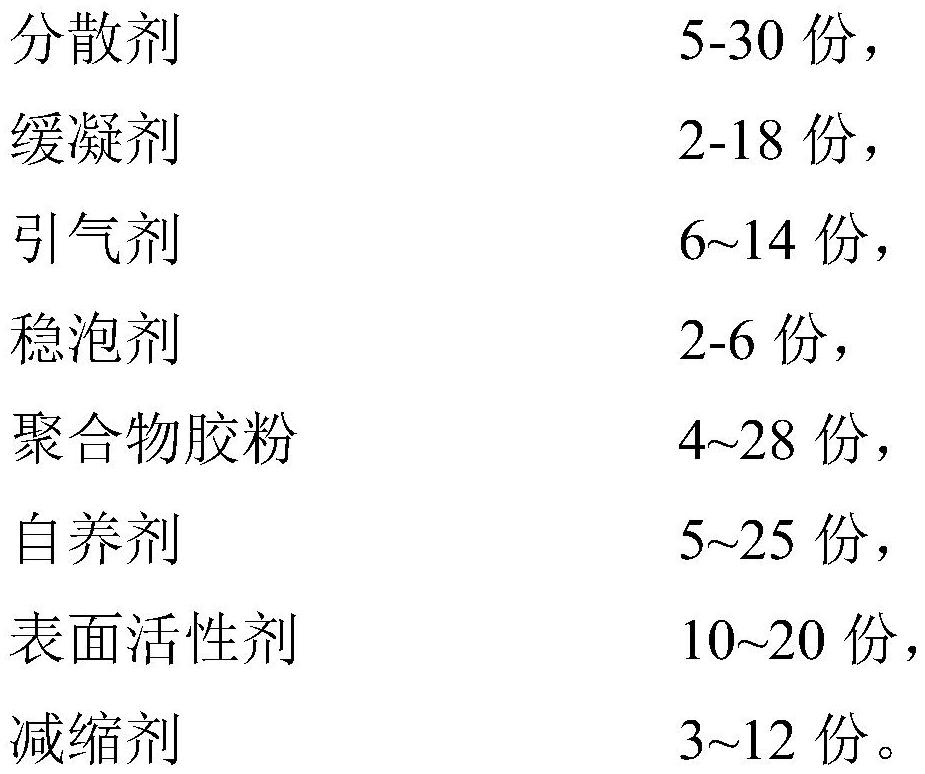

[0022] Embodiment 1-a concrete crack inhibitor for face dams comprises the following raw material components: 5 parts of dispersants, 2 parts of retarders, 6 parts of air-entraining agents, 2 parts of foam stabilizers, 4 parts of polymer rubber powder, 5 parts of nourishing agent, 10 parts of surfactant, 3 parts of shrinkage reducer;

[0023] Wherein, the dispersant includes a mixture of vinyl acetate-higher fatty acid vinyl ester binary copolymer, acrylate and styrene binary copolymer with a mass ratio of 0.5:0.8;

[0024] The retarder includes a mixture of salicylic acid modified hydroxyethyl methylcellulose ether retarder and citric acid modified methylcellulose ether retarder with a mass ratio of 0.6:0.9;

[0025] The air-entraining agent includes a mixture of modified rosin thermopolymer air-entraining agent, alkylbenzenesulfonate polymer air-entraining agent and saponin polymer air-entraining agent with a mass ratio of 0.2:1.0:0.4;

[0026] The foam stabilizer includes ...

Embodiment 2

[0031] Embodiment 2-a concrete crack inhibitor for face dams, according to the ratio of parts by weight, includes the following raw material components: 30 parts of dispersant, 18 parts of retarder, 14 parts of air-entraining agent, 6 parts of foam stabilizer, polymer 28 parts of rubber powder, 25 parts of autotrophic agent, 20 parts of surfactant, 12 parts of shrinkage reducing agent.

[0032] Wherein, the dispersant includes a mixture of vinyl acetate-higher fatty acid vinyl ester binary copolymer, acrylate and styrene binary copolymer with a mass ratio of 2.5:2.8;

[0033] The retarder includes a mixture of salicylic acid modified hydroxyethyl methylcellulose ether retarder and citric acid modified methylcellulose ether retarder with a mass ratio of 2.8:1.8;

[0034] The air-entraining agent includes a mixture of modified rosin thermopolymer air-entraining agent, alkylbenzenesulfonate polymer air-entraining agent and saponin polymer air-entraining agent with a mass ratio of...

Embodiment 3

[0040] Embodiment 3-a concrete crack inhibitor for face dams comprises the following raw material components according to the ratio in parts by weight: 20 parts of dispersants, 10 parts of retarders, 12 parts of air-entraining agents, 5 parts of foam stabilizers, polymers 20 parts of rubber powder, 20 parts of autotrophic agent, 16 parts of surfactant, 9 parts of shrinkage reducing agent.

[0041] Wherein, the dispersant includes a mixture of vinyl acetate-higher fatty acid vinyl ester binary copolymer, acrylate and styrene binary copolymer with a mass ratio of 1.5:1.8;

[0042] The retarder includes a mixture of salicylic acid modified hydroxyethyl methylcellulose ether retarder and citric acid modified methylcellulose ether retarder with a mass ratio of 1.7:1.3;

[0043] The air-entraining agent includes a mixture of modified rosin thermopolymer air-entraining agent, alkylbenzenesulfonate polymer air-entraining agent and saponin polymer air-entraining agent with a mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com