A coagulation and early strength agent for 3D printing cement-based materials

A technology of cement-based materials and accelerated coagulation and early strength, applied in the field of coagulation accelerators, can solve the problems of long setting time and high price of fast-hardening sulfoaluminate cement, and achieve short hardening time, excellent performance over time, shortened The effect of clotting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A coagulation early-strength agent for 3D printing cement-based materials, including random copolymers polymerized from the following monomers: 60 parts by weight of unsaturated polyether, 25 parts by weight of unsaturated carboxylic acid, 20 parts by weight of Polar unsaturated monomer; also includes: 10 parts of chitosan-coated calcium fluoroaluminate.

[0028] Its preparation method comprises the following steps:

[0029] (1) Preparation of chitosan-coated calcium fluoroaluminate: under constant temperature conditions, in an aqueous solution of chitosan and acetic acid, calcium fluoroaluminate and epichlorohydrin are sequentially heated and stirred to react to obtain chitosan-coated calcium fluoroaluminate. Calcium fluoroaluminate; wherein, the mass ratio of calcium fluoroaluminate, chitosan and epichlorohydrin is 1:1:2;

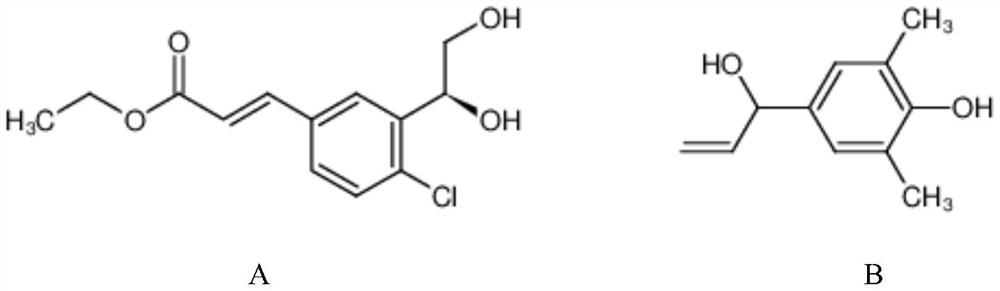

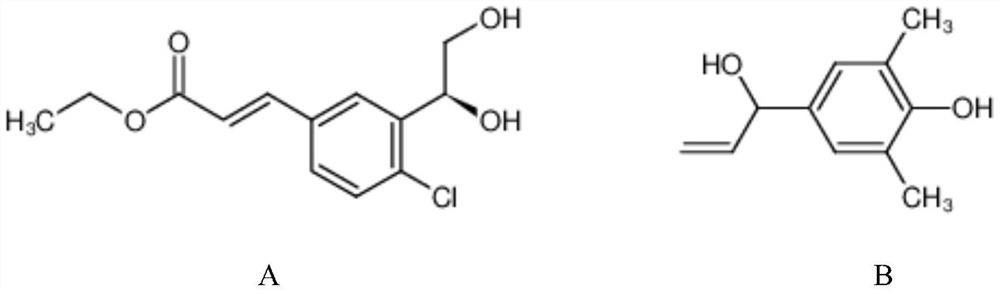

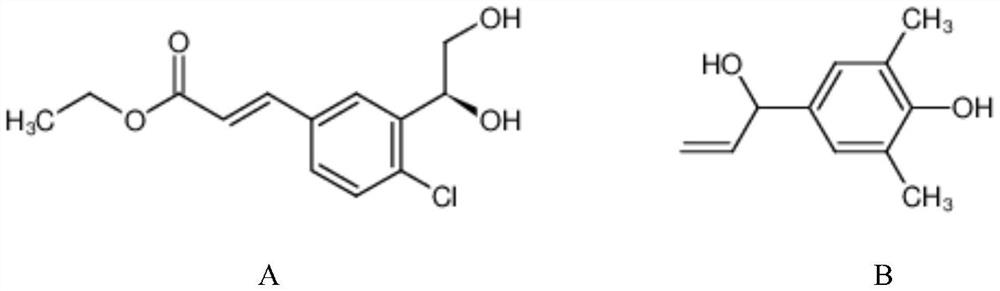

[0030] (2) Preparation of random copolymer: add unsaturated polyether, unsaturated carboxylic acid and polar unsaturated monomer into the reactio...

Embodiment 2

[0040] A coagulation early-strength agent for 3D printing cement-based materials, including a random copolymer polymerized from the following monomers: 70 parts by weight of unsaturated polyether, 15 parts by weight of unsaturated carboxylic acid, 3 parts by weight of Polar unsaturated monomer; also includes: 20 parts of chitosan-coated calcium fluoroaluminate.

[0041] Its preparation method comprises the following steps:

[0042] (1) Preparation of chitosan-coated calcium fluoroaluminate: under constant temperature conditions, in an aqueous solution of chitosan and acetic acid, calcium fluoroaluminate and epichlorohydrin are sequentially heated and stirred to react to obtain chitosan-coated calcium fluoroaluminate. Calcium fluoroaluminate; wherein, the mass ratio of calcium fluoroaluminate, chitosan and epichlorohydrin is 2:1:1;

[0043] (2) Preparation of random copolymer: add unsaturated polyether, unsaturated carboxylic acid and polar unsaturated monomer into the reactio...

Embodiment 3

[0053] A coagulation early strength agent for 3D printing cement-based materials, including a random copolymer polymerized from the following monomers: 65 parts by weight of unsaturated polyether, 20 parts by weight of unsaturated carboxylate, 10 parts by weight The polar unsaturated monomer; also includes: 15 parts of chitosan-coated calcium fluoroaluminate.

[0054] Its preparation method comprises the following steps:

[0055] (1) Preparation of chitosan-coated calcium fluoroaluminate: under constant temperature conditions, in an aqueous solution of chitosan and acetic acid, calcium fluoroaluminate and epichlorohydrin are sequentially heated and stirred to react to obtain chitosan-coated calcium fluoroaluminate. Calcium fluoroaluminate; wherein, the mass ratio of calcium fluoroaluminate, chitosan and epichlorohydrin is 1.5:1:1.5;

[0056] (2) Preparation of random copolymer: add unsaturated polyether, unsaturated carboxylate and polar unsaturated monomer into the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com