Full-automatic marking machine for folding carton

A fully automatic, carton technology, applied in typewriters, printing, etc., can solve the problems of inability to fully realize automatic marking, low marking force control accuracy, and affecting marking effects, so as to achieve good marking effects and save labor costs , Improve the effect of marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

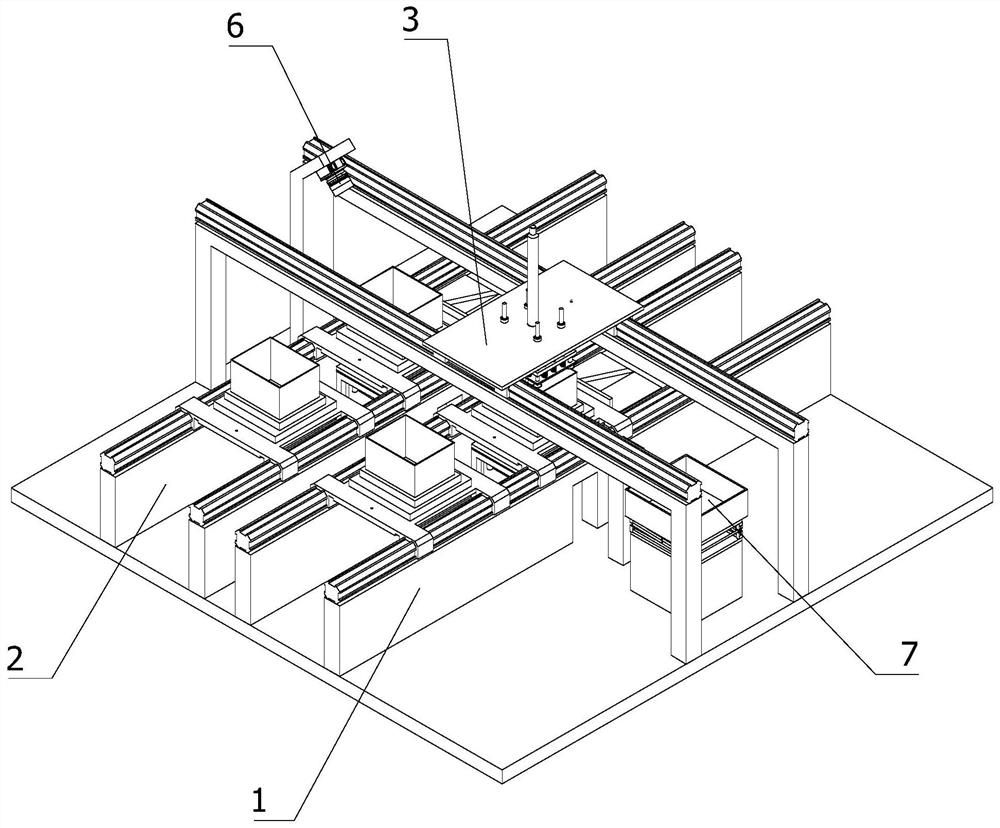

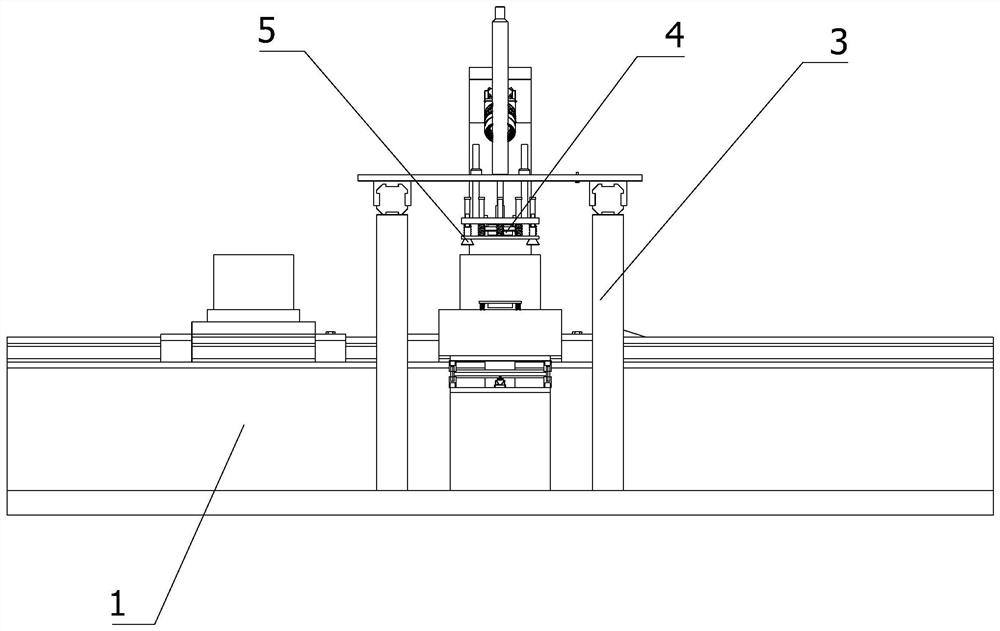

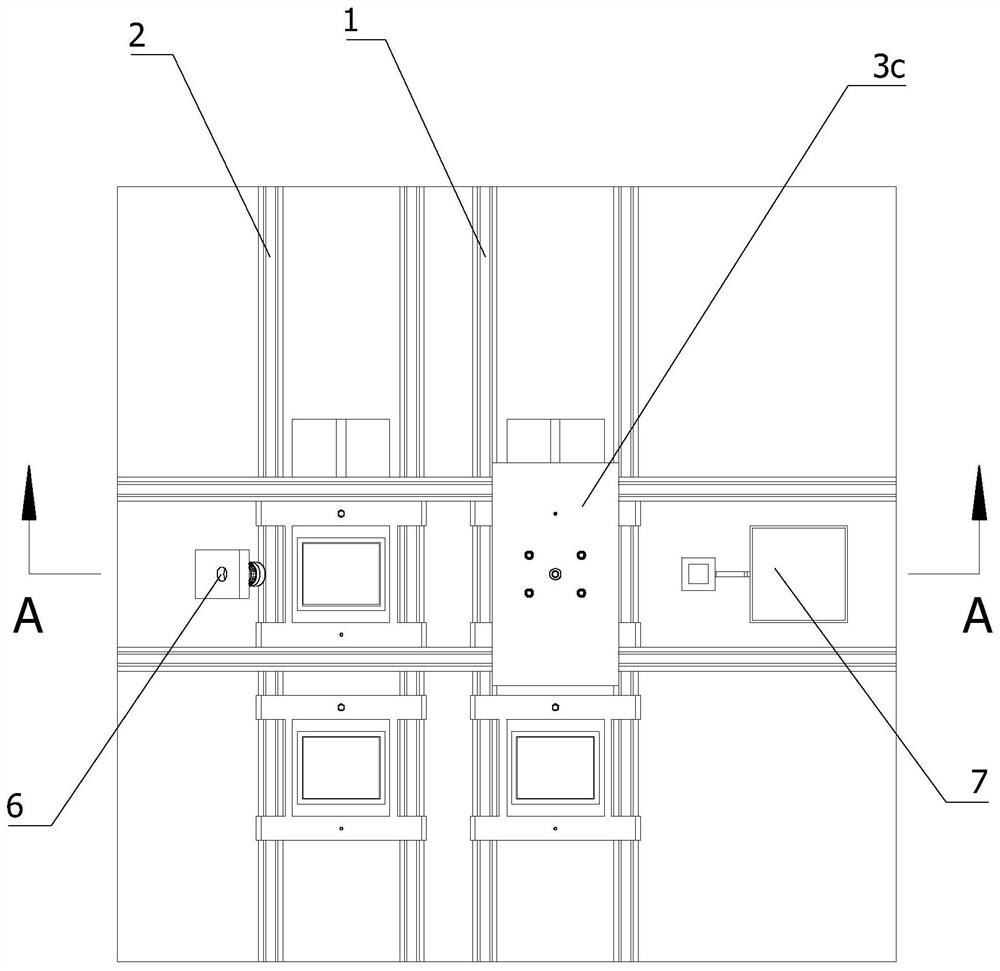

[0084] Such as figure 1 , figure 2 , image 3 and Figure 7 The folding carton automatic marking machine shown includes a first material transfer mechanism 1, a second material transfer mechanism 2, a third material transfer mechanism 3, a marking mechanism 4, a grasping mechanism 5, an ink amount detection mechanism 6 and Ink replenishment mechanism 7;

[0085] The first material shifting mechanism 1 is installed on the frame and is used to move the feeding material box equipped with folding cartons;

[0086] The second material shifting mechanism 2 is arranged on the frame in parallel with the first material moving mechanism 1, and has the same structure as the first material moving mechanism 1, and is used to move the empty material box;

[0087] The third material shifting mechanism 3 is installed on the frame, spans the first material moving mechanism 1 and the second material moving mechanism 2, and is used to drive the marking mechanism 4 and the grasping mechanism...

Embodiment 2

[0134] Such as Figure 8 and Figure 9 As shown, compared with Embodiment 1, in this embodiment, the grabbing mechanism 5 includes a telescopic installation frame 5a, a third guide rod 5b, a first spring 5c and a vacuum suction cup 5d;

[0135] The telescopic installation frame 5a is mounted on the bottom of the working end of the third material shifting mechanism 3 so as to be movable in the vertical direction, and is used for installing the vacuum suction cup 5d;

[0136] The third guide rod 5b is evenly and vertically distributed on the top of the telescopic installation frame 5a, and cooperates with the working end of the third material shifting mechanism 3 in the vertical direction;

[0137] The first spring 5c is sleeved on the first spring 5c and is between the top of the telescopic installation frame 5a and the bottom of the working end of the third material transfer mechanism 3, so that the vacuum suction cup 5d is lower than the marking mechanism 4 in the non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com