A large-scale composite winding body mandrel device

A technology of composite material and winding body, which is applied in the field of composite material winding shell mandrel, can solve the problems such as the reduction of the support span of the outer mold, and achieve the effects of solving deflection deformation, ensuring performance, and improving molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the following describes the specific implementation and operation of a large-scale composite material wound core mold device according to the present invention with reference to the accompanying drawings and preferred embodiments. The principle is explained in detail.

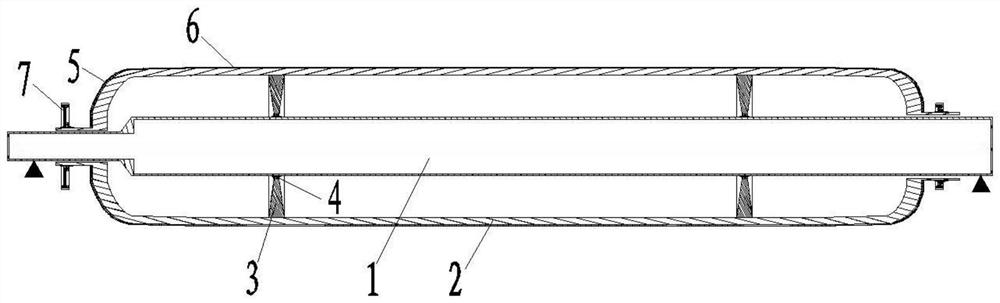

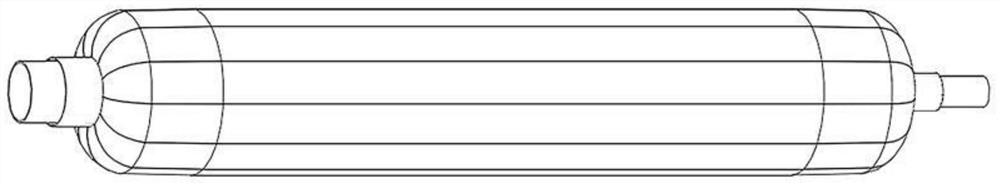

[0037] like figure 1 As shown, the large-scale composite material wound body core mold device provided by the embodiment of the present invention uses the mandrel 1 to park on the winding station, and connects the outer mold 2 through the driving device to realize the rotation of the outer mold 2, thereby realizing the winding function.

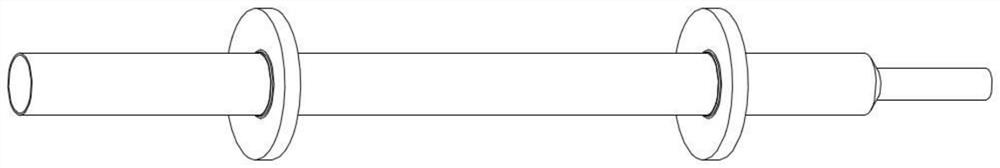

[0038] The connection structure between the mandrel 1, the self-aligning bearing 4, and the bearing seat 5 is as follows: figure 2 As shown, the inner rings of the two self-aligning bearings 4 are connected to the mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com