Production equipment for high-toughness polypropylene film

A polypropylene film and production equipment technology, applied in the field of tough polypropylene film production equipment, can solve the problems of uneven end faces on the left and right sides, and achieve the effect of ensuring the accuracy of the film width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] as attached figure 1 to attach Figure 5 Shown:

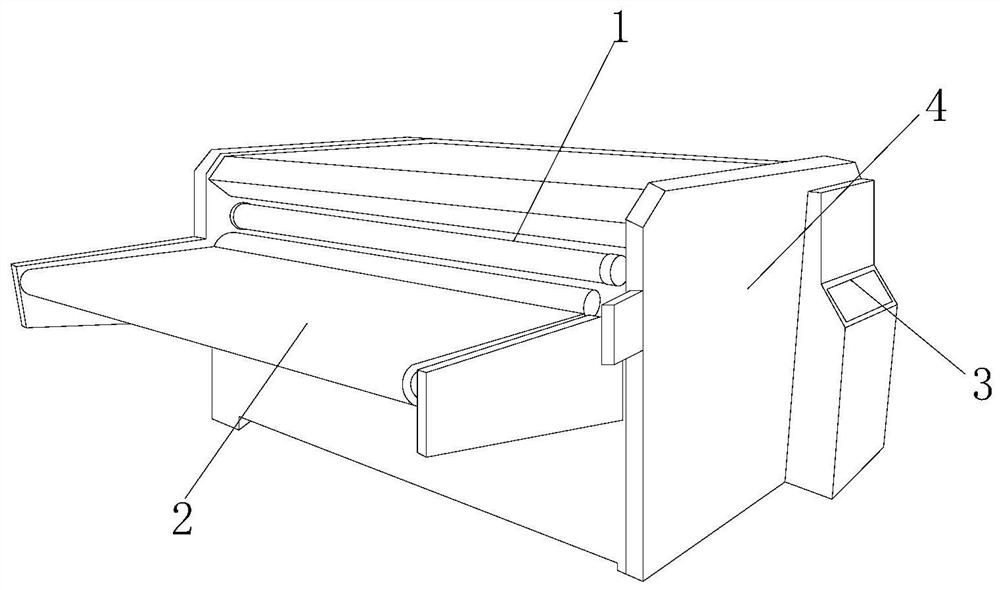

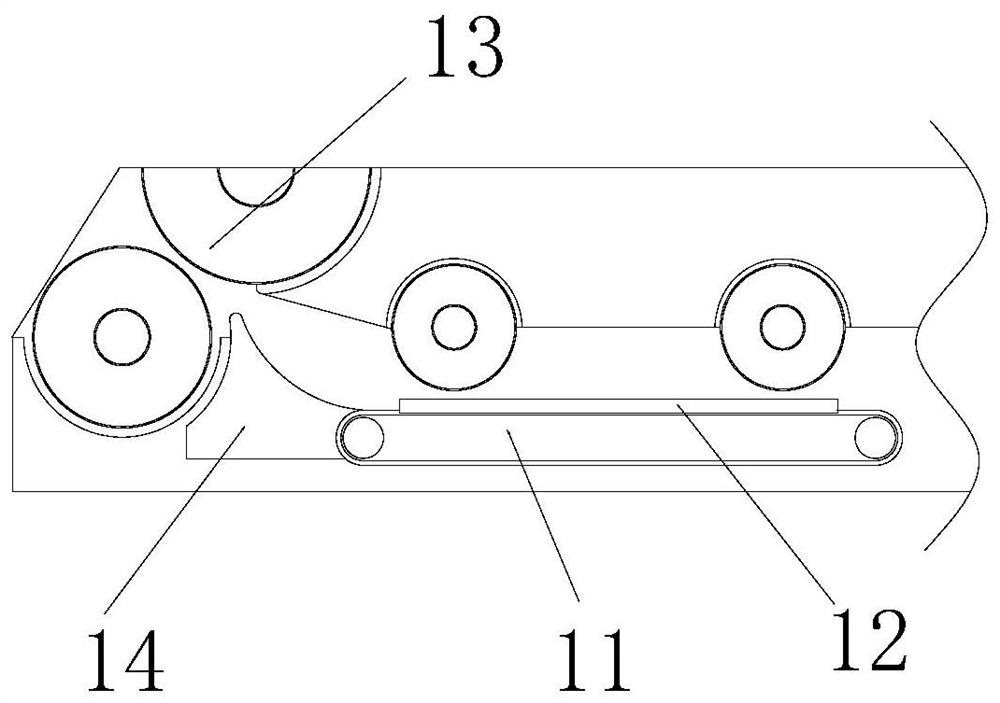

[0026] The present invention provides a kind of strong and tough polypropylene film production equipment, its structure comprises extruding mechanism 1, placing table 2, control panel 3, machine body 4, and described extruding mechanism 1 is inlayed on the top of machine body 4, and described placing The platform 2 is embedded and installed on the left end surface of the body 4, and the control panel 3 is installed on the outer side of the extrusion mechanism 1 by welding, and the outer end surface of the body 4 is attached to the control panel 3; the extrusion mechanism 1 It includes a transmission mechanism 11, a shaping mechanism 12, an extrusion wheel 13, and an arc block 14. The transmission mechanism 11 is embedded and installed on the right side of the arc block 14, and the shaping mechanism 12 is embedded so that it can be fitted on On the upper end surface of the transmission mechanism 11 , the extrusion wheel...

Embodiment 2

[0032] as attached Figure 5 to attach Figure 7 As shown: the transmission mechanism 11 includes a conveyor belt 111, a power wheel 112, and a cutting mechanism 113. The conveyor belt 111 is attached and wrapped on the outer end surface of the power wheel 112. The power wheel 112 is symmetrically installed on the upper and lower ends of the cutting mechanism 113. The cutting mechanism 113 is inlaid and connected to the conveyor belt 111, and the left and right sides of the outer contour of the conveyor belt 111 are provided with grooves inlaid with the cutting mechanism 113, which can effectively guide the protruding part of the film to be fixed.

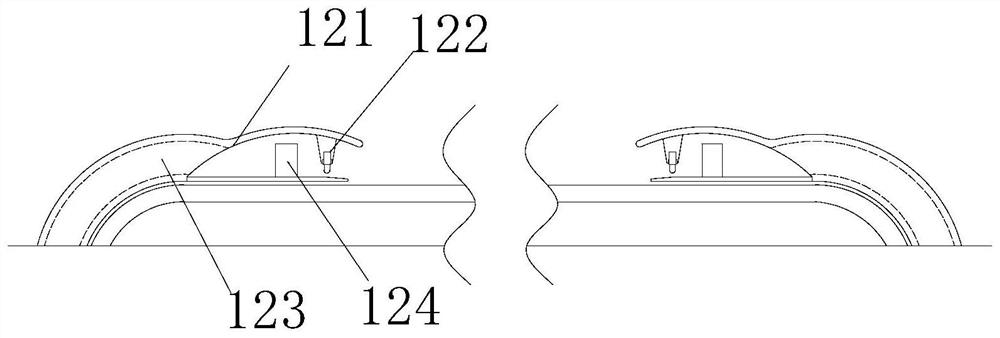

[0033] Wherein, the cutting mechanism 113 includes a cutting wheel 131, an inlay groove 132, and a fitting wheel 133. The cutting wheel 131 is symmetrically installed on the left and right ends of the fitting wheel 133, and the inlay groove 132 is inlaid in the cutting mechanism. 113, the fitting wheel 133 fits and connects the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com