A method for stable coiling of ultra-thin patterned plate

A checkered plate and specification technology, which is applied in the field of stable coiling of ultra-thin checkered plate, can solve the problems of increasing roll consumption, affecting rolling stability, and difficulty in achieving uniform thickness changes of the plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

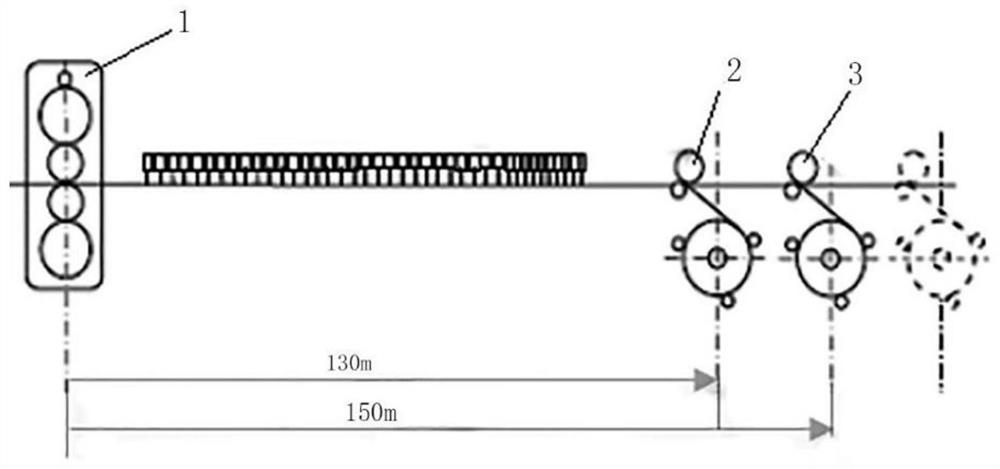

Image

Examples

Embodiment

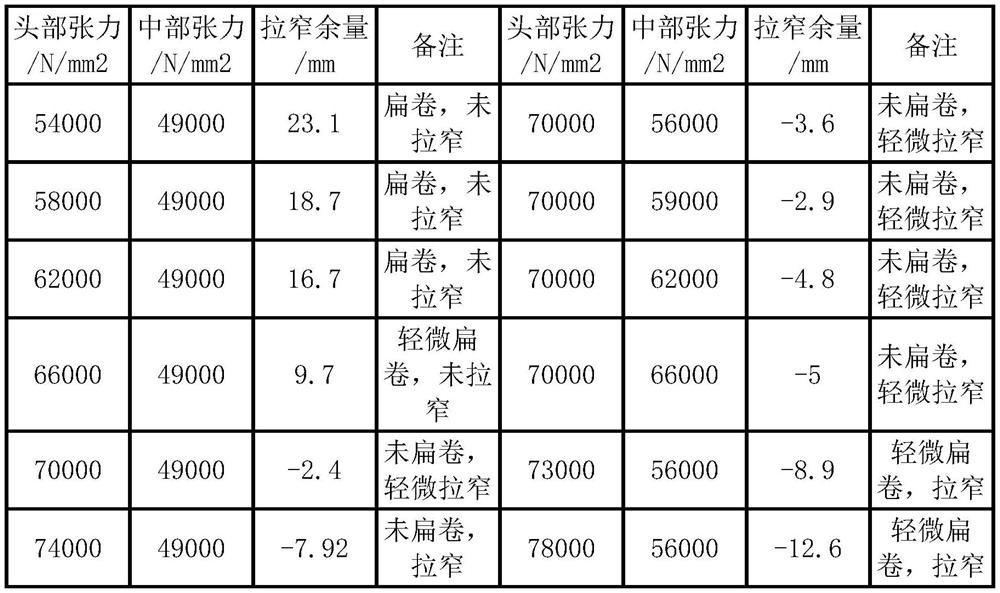

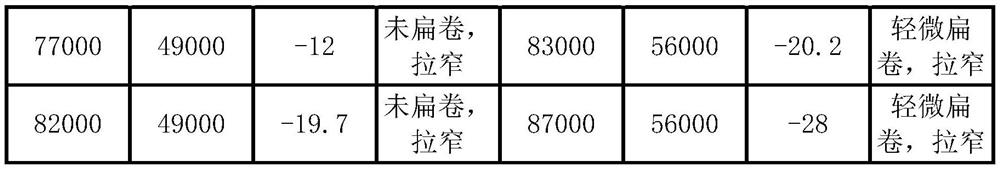

[0026] In this example, the production steel symbol GR3180F2 of the strip, the specification is changed from 1.5mm×1000mm to 1.2mm×1000mm, the target coiling temperature is 590°C, and the measured temperature range is 571°C~613°C at 590°C±30°C scope.

[0027] The method for stably coiling the ultra-thin size pattern plate of the present embodiment includes the following steps:

[0028] Step 1. In the finishing rolling stage, it is determined whether the strip steel is variable thickness rolling. If it is variable thickness rolling, according to the initial strip thickness and target thickness, in the coiling stage, step 2-step 4 is performed in sequence. In this embodiment, the specification of the strip is changed from 1.5mm×1000mm to 1.2mm×1000mm, so it is rolling with variable thickness, and steps 2-4 are performed in sequence during the coiling stage.

[0029] If it is not rolling with variable thickness, the target thickness is used as the initial strip thickness, and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com