Remediation agent for heavy metal industrial contaminated site and remediation method thereof

A technology for repairing chemicals and heavy metals, applied in the restoration of contaminated soil, chemical instruments and methods, agriculture, etc., can solve problems such as small scope of application, monotonous and fixed formula, and lack of standardized operating procedures, so as to improve the repair effect and improve the restoration efficiency. Efficiency, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

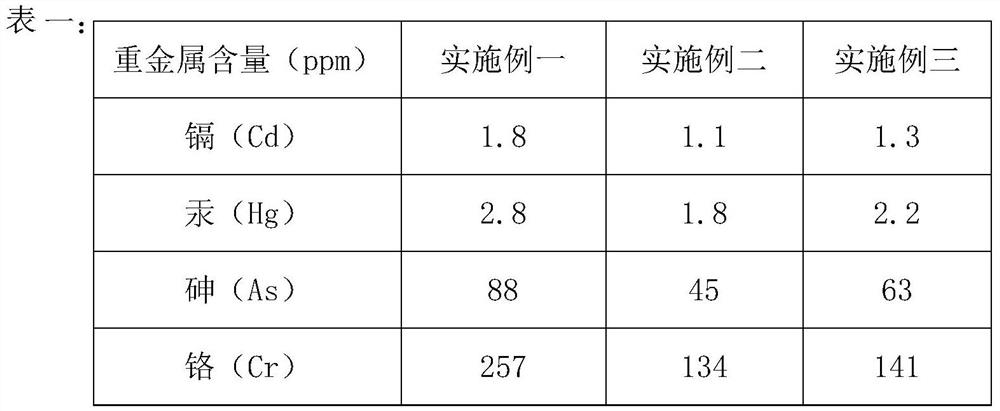

Embodiment 1

[0024] A remediation agent for heavy metal industrial contaminated sites, including 60% of agent a, 20% of agent b and 20% of agent c,

[0025] The mass components of the agent a are as follows: 30 parts of inorganic alkaline substances, 40 parts of fly ash;

[0026] Wherein, the inorganic alkaline substance is any one or more of limestone, quicklime, soda ash, caustic soda, magnesium oxide, magnesium hydroxide, cement, and industrial composite alkali.

[0027] The mass components of agent b are as follows: 30 parts of phosphates (calcium hydrogen phosphate), 30 parts of calcium polysulfide, 20 parts of dithiocarbamate-based salts, 12 parts of humic acid, 5 parts of molasses, iron manganese oxide 8 copies;

[0028] Among them, any one or more of calcium hydrogen phosphate, trisodium phosphate, sodium dihydrogen phosphate, tripotassium phosphate, and potassium dihydrogen phosphate is used as the phosphate.

[0029] The mass components of the agent c are as follows: 20 parts o...

Embodiment 2

[0036] A remediation agent for heavy metal industrial contaminated sites, including 70% of agent a, 15% of agent b and 15% of agent c,

[0037] The mass components of the agent a are as follows: 35 parts of inorganic alkaline substances, 45 parts of fly ash;

[0038] Wherein, the inorganic alkaline substance is any one or more of limestone, quicklime, soda ash, caustic soda, magnesium oxide, magnesium hydroxide, cement, and industrial composite alkali.

[0039] The mass components of agent b are as follows: 25 parts of phosphates (calcium hydrogen phosphate), 5 parts of calcium polysulfide, 15 parts of dithiocarbamate salts, 10 parts of humic acid, 4 parts of molasses, iron manganese oxide 7 copies;

[0040] Among them, any one or more of calcium hydrogen phosphate, trisodium phosphate, sodium dihydrogen phosphate, tripotassium phosphate, and potassium dihydrogen phosphate is used as the phosphate.

[0041] The mass components of the agent c are as follows: 15 parts of diato...

Embodiment 3

[0048] A remediation agent for heavy metal industrial contaminated sites, including 80% of agent a, 10% of agent b and 10% of agent c,

[0049] The mass components of the agent a are as follows: 40 parts of inorganic alkaline substances, 50 parts of fly ash;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com