A non-uniform curved surface fly-eye lens and its preparation method

A curved surface compound eye and lens technology, applied in the direction of lenses, instruments, optics, etc., can solve problems such as defocusing, and achieve the effect of uniform surface morphology, good repeatability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

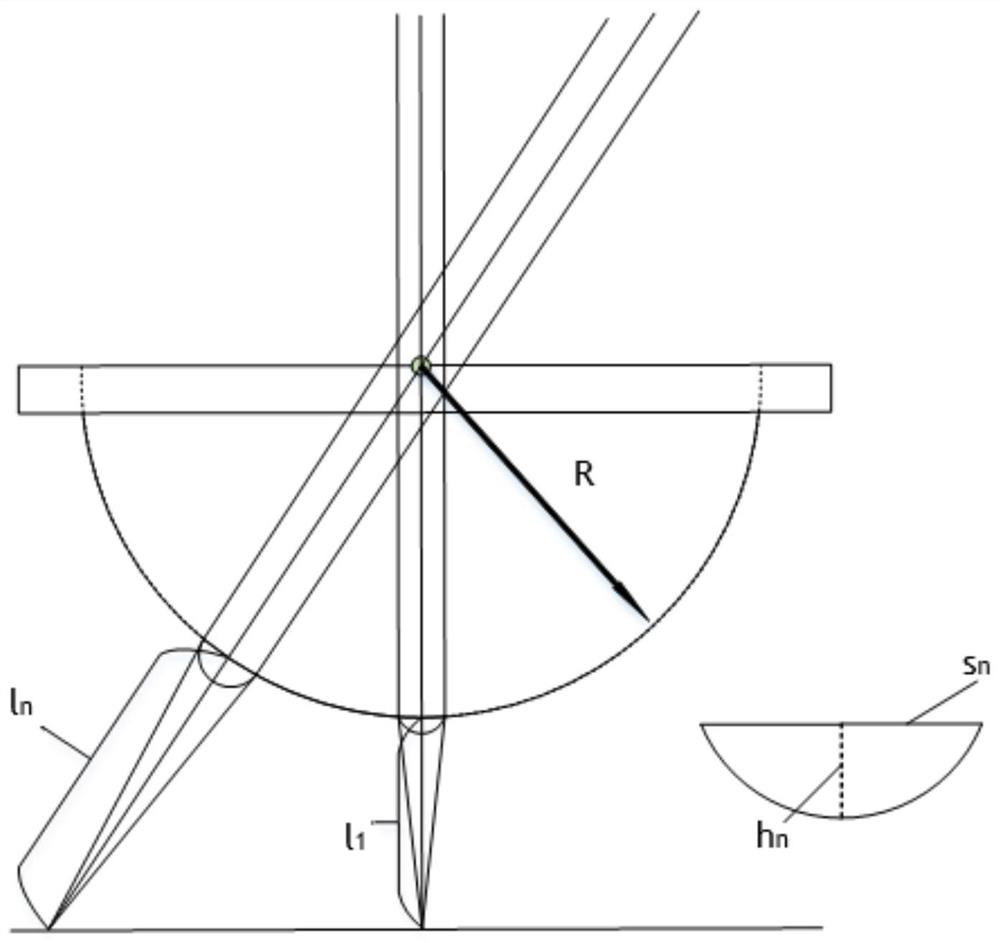

[0050] figure 1 A schematic diagram of the design method of a non-uniform curved surface compound eye lens of the present invention is shown.

[0051] Such as figure 1 As shown, it is an innovative design scheme of a double pumping curved surface fly eye lens. The core idea of the design of the non-uniform sub-eye is to make the focal length of each sub-eye different. non-uniform arrangement to achieve. Light rays of different angles enter from the plane end of the curved surface fly-eye lens and exit from the curved surface end, which coincides with the optical axis of each sub-eye. Assuming that the central sub-eye is a first-level sub-eye, the distance from it to CMOS is l 1 , it can be defaulted that its object-space focal length f′ is equal to l 1 , extending from the first-level sub-eye to the periphery, respectively l 2 , l 3 ...l m , l m As the number of sub-eyes increases, the larger the value, the defocus problem of the curved surface fly-eye lens is solved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com