Cavitation jet sludge cleaning device

A technology for clearing equipment and sludge, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. It can solve problems such as low work efficiency, poor operation stability, and short service life, and achieve work High efficiency, long service life and good operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

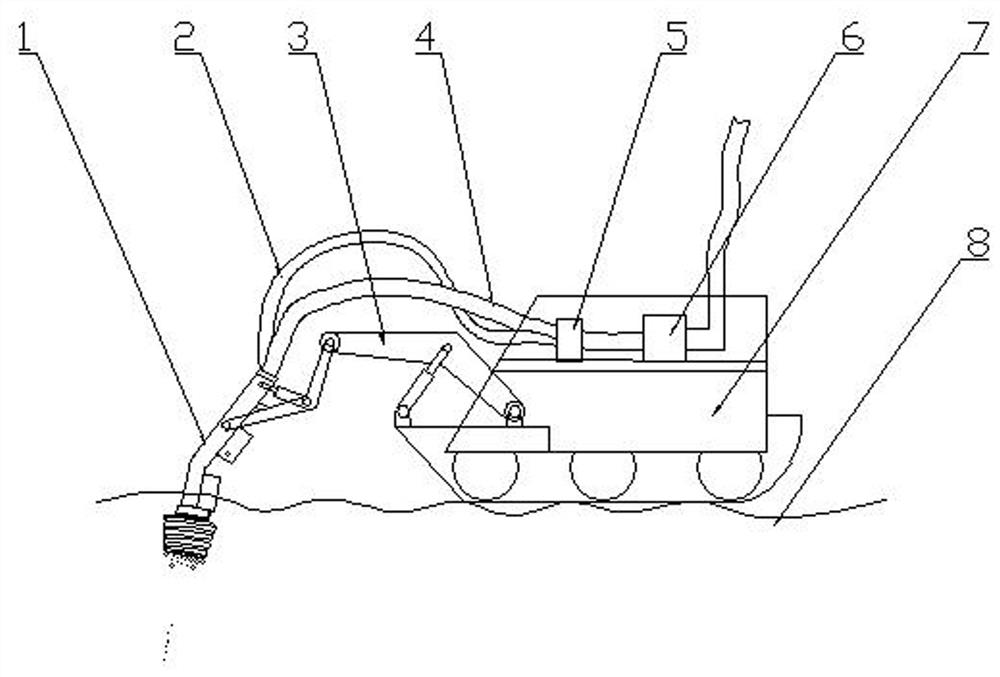

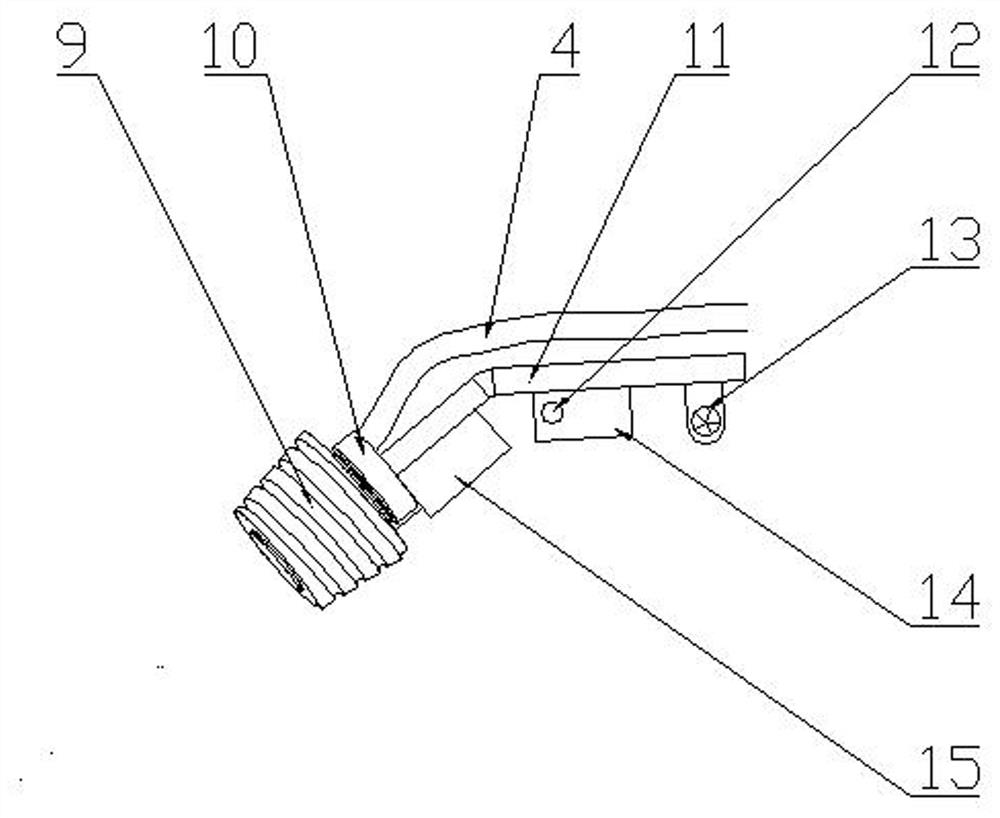

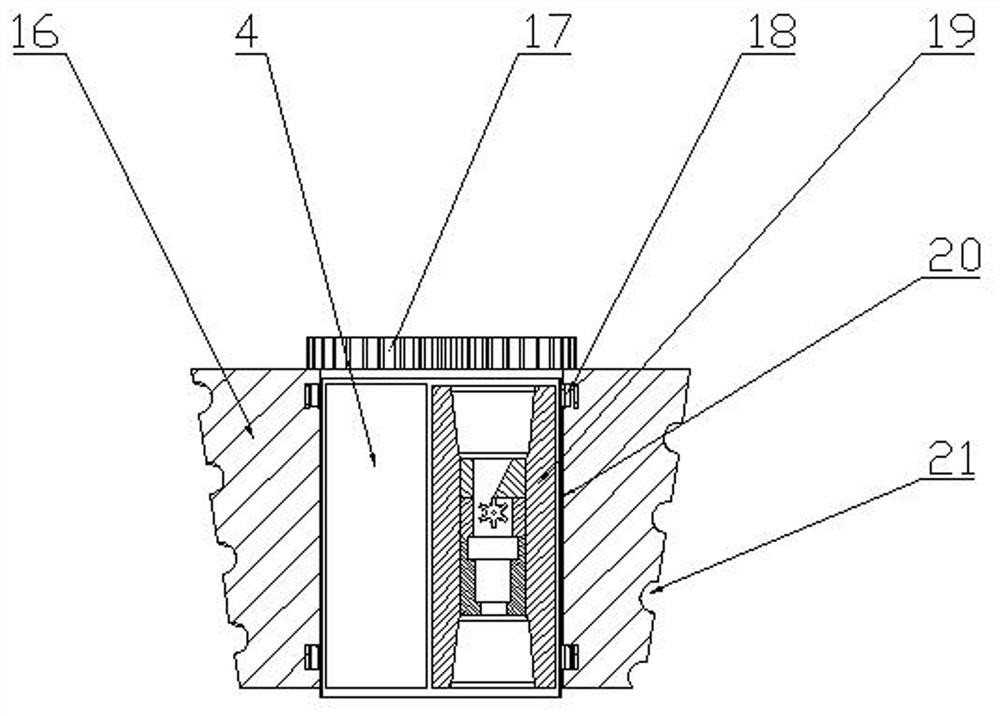

[0023] Example: as Figure 1-4 As shown, a cavitation jet sludge cleaning device includes an underwater sludge layer 8, and the underwater sludge layer 8 is provided with a dredging underwater operation vehicle 7, and the front end of the dredging underwater operation vehicle 7 is provided with a cavitation jet sludge cleaning Mechanism 1, a mechanical arm 3 is provided between the cavitation jet sludge cleaning mechanism 1 and the dredging underwater operation vehicle 7, and a suction pump 6 is provided on the dredging underwater operation vehicle 7, and the suction pump 6 and the cavitation jet sludge cleaning A sludge conveying pipe 4 extending out of the water surface is provided between the mechanism 1, a jet pump 5 is provided on the side of the suction pump 6, and a jet pipe 2 is provided between the jet pump 5 and the cavitation jet sludge cleaning mechanism 1. The cavitation jet sludge cleaning mechanism 1 includes a stirring and suction assembly 9 , a rocker arm 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com