Mine curve car pusher

A technology of carts and curves, which is applied in the direction of mechanical equipment, engine components, railway car body parts, etc., and can solve the problems of shortened service life of carts, inability of carts to work, and lack of protection and maintenance of carts Measures and other issues to achieve the effect of increasing the moving speed and convenient and efficient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

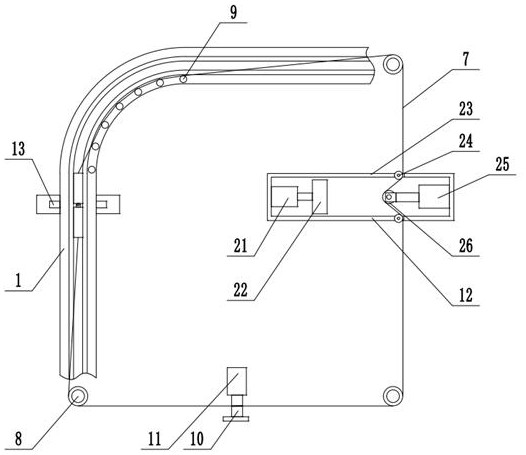

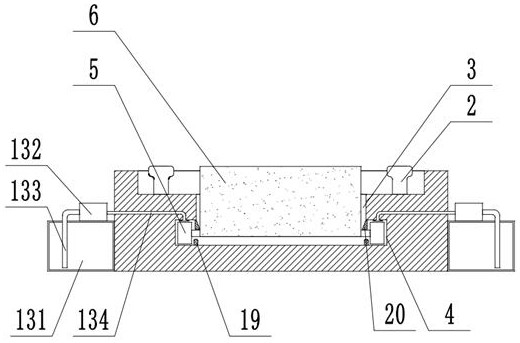

[0023] see Figure 1-3 , mine curve cart machine, including a slideway 1 with a curve, two sets of guide rails 2 are fixedly installed in the slideway 1, and a trolley groove 3 is opened on the slideway 1 between the two sets of guide rails 2, and the pusher The left and right inner walls of the car groove 3 are respectively provided with rolling grooves 4 in the slideway 1. The cart body 6 is placed in the cart groove 3. The bottom of the body 6 is rotated around and installed with a roller 5 located in the rolling groove 4. The curved part There are multiple sets of guide shafts 9 distributed at equal intervals on the top of the slideway 1, multiple sets of turning rollers 8 are installed on the foundation outside the slideway 1, and the front and rear ends of the body 6 are fixedly connected with the guide shafts 9 and the turning rollers 8. The closed steel rope 7 is slidably connected. The transmission drum 10 is slidably connected to the steel rope 7. The transmission dr...

Embodiment 2

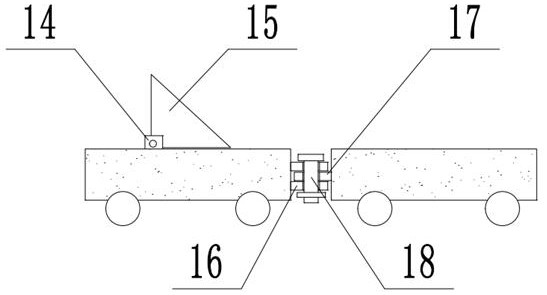

[0025] On the basis of Embodiment 1, a connection plate 16 and a clamping plate 17 are fixedly installed on the opposite side walls of the left and right groups of bodies 6, respectively, and the connecting plate 16 and the clamping plate 17 are respectively provided with through holes. The fixed pin shaft 18 is detachably installed with the clamping plate 17 through the through hole, and the left and right two groups of bodies 6 can be rotated and connected through the fixed pin shaft 18 to facilitate movement on the curved part of the slideway 1. The lubricating part 13 includes a fixed On the fuel tank 131 on the left and right sides of the slideway 1, a pump 132 is fixedly installed on the top of the fuel tank 131. The pump 132 is connected with an oil guide pipe 133 leading to the inside of the fuel tank 131. The pump 132 is connected with a rolling groove 4 extending to the slideway 1. The oil delivery pipe 134 inside pumps the lubricating oil in the oil tank 131 into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com