Hot-line work type overhead bare conductor insulating material automatic coating equipment

A technology for wire insulation and live work, which is applied to coatings, devices for coating liquid on the surface, etc., can solve the problems of low efficiency, low efficiency of power failure operations, difficult operation, etc., and achieve compact overall structure, good action consistency, The effect of optimal automation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

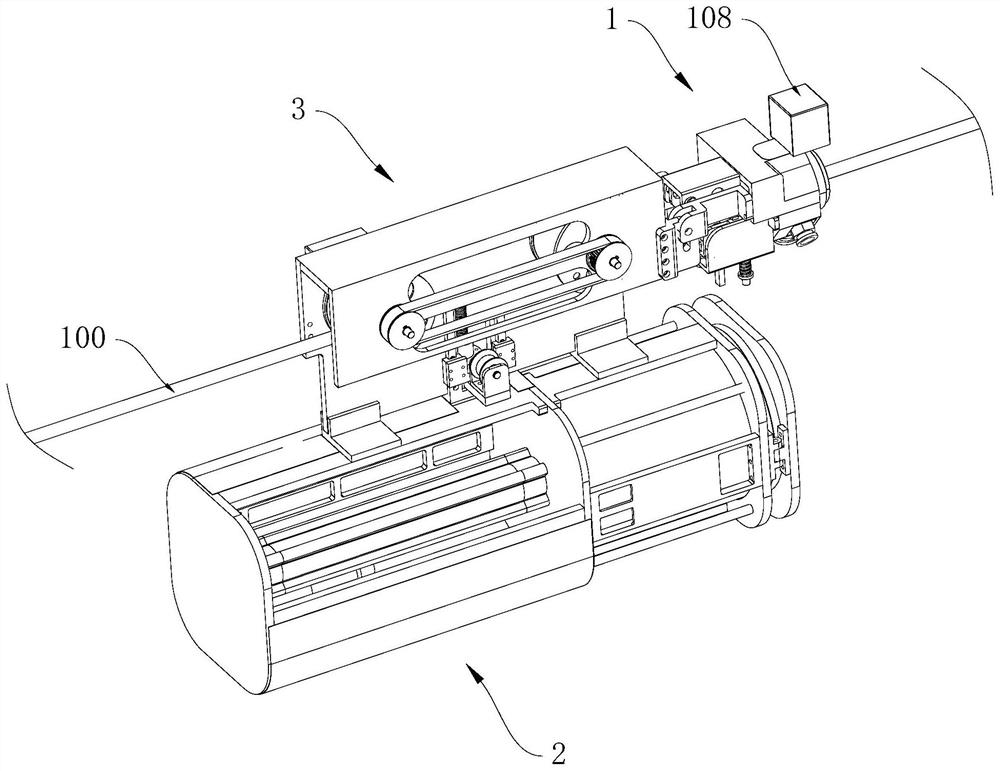

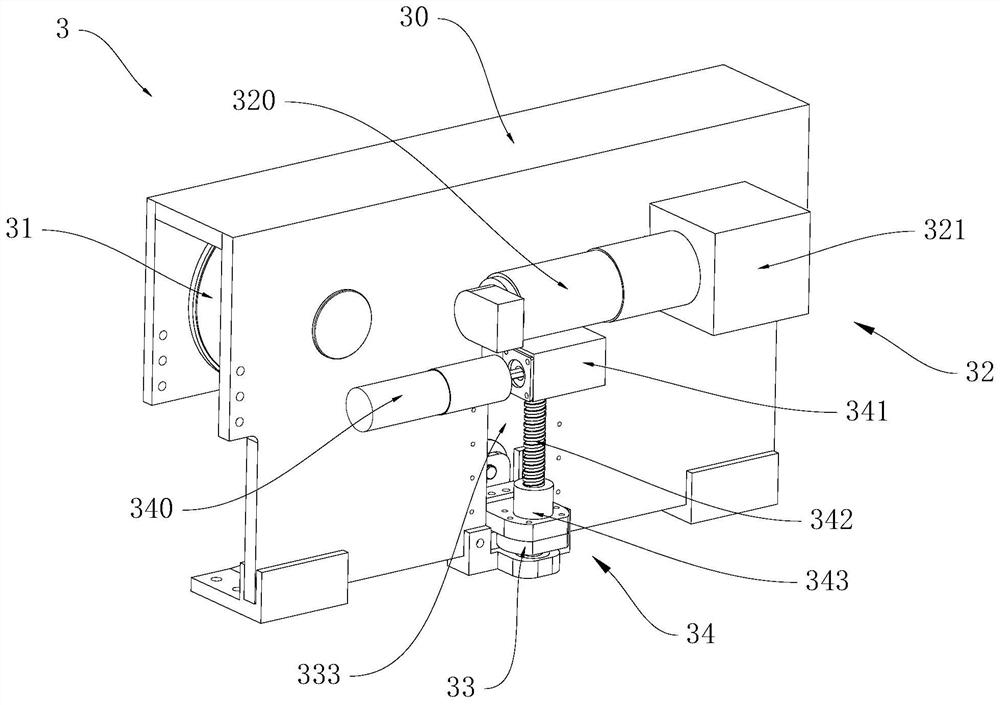

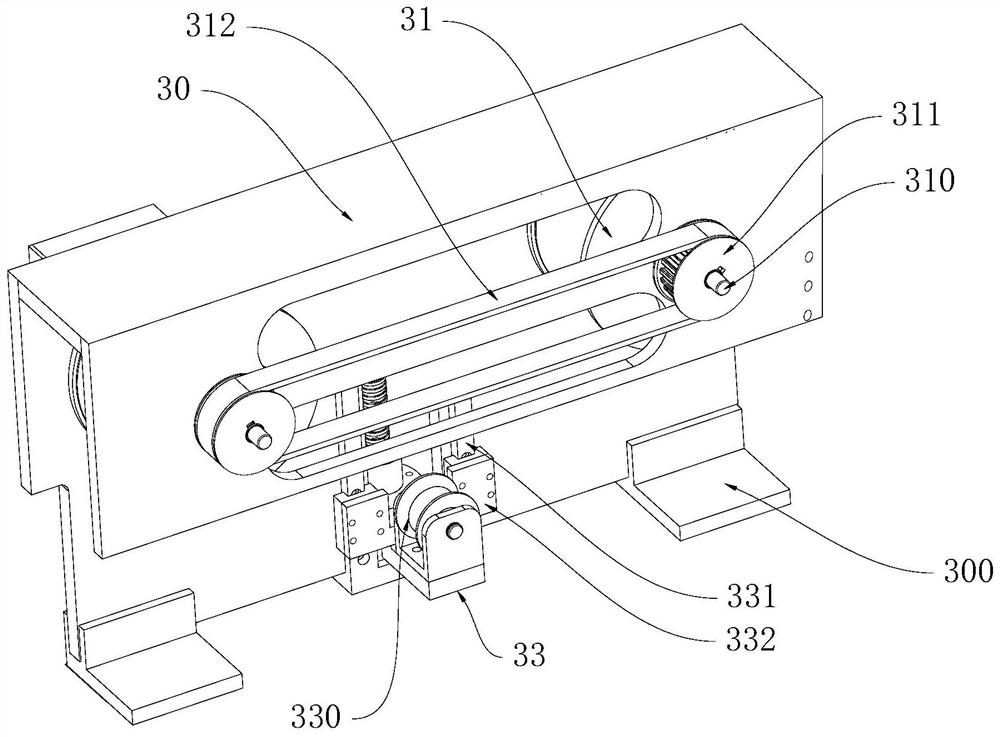

[0042] This embodiment proposes an automatic coating equipment for live-work type overhead bare wire insulation material, combined with Figure 1 to Figure 6 As shown, it includes:

[0043] A coating device 1, used to coat the surface of the bare wire 100 with an insulating material;

[0044] A material supply device 2, used to deliver insulating material to the coating device 1;

[0045] A traction device 3, placed on the bare wire 100, the coating device 1 and the material supply device 2 are respectively connected to the traction device 3, the traction device 3 is used to walk on the bare wire 100 and drive the The coating device 1 and the material supply device 2 move relative to the bare wire 100 .

[0046] In the above equipment, the traction device 3 is directly connected to the front end of the coating device 1, and the material supply device 2 is arranged on the traction device 3, driven by the traction device 3, the coating device can be driven 1 Coating insulatin...

Embodiment 2

[0062] At present, the coating device for overhead bare wires mostly adopts a wheel structure to support the wire to the coating head. However, due to the weight of the coating head itself and the tension of the pipeline for conveying insulating materials, The edge generally has a tendency to sink, which causes the insulating coating to be eccentric, that is, the thickness of the upper half arc surface of the bare wire coating is thinner, and the thickness of the lower half arc surface coating is thicker. Due to the short plate effect of the voltage resistance, It is necessary to consume a large amount of insulating material to achieve the thickness of the insulating coating to withstand the voltage requirement, which not only leads to waste of insulating material, but also unsatisfactory coating effect. In addition, the shell covering the upper and lower sides of the bare wire cannot be installed automatically, so it is difficult to meet the operating requirements of the live ...

Embodiment 3

[0075] At present, overhead transmission lines are widely distributed, long distance, and line environment is complex. Overhead lines have become the main form of power transmission. The complete and stable operation of overhead lines directly affects the reliability of the power supply system. Regular inspection and maintenance of overhead lines is a must for all The important work content of the municipal power supply department. In the existing technology, manual inspection is mostly used for inspection and maintenance of overhead lines. This method has low efficiency, poor precision, and high risk factor. With the development of robot technology, more and more robots replace humans. Working in harsh environments and complex processes, how to quickly and reliably hoist the robot to the designated line position and remove the robot after the robot completes the specific task is the key to the large-scale application and promotion of the robot technology. At present, in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com