Calcium carbonate liquid stirring equipment for calcium carbonate production

A mixing equipment and calcium carbonate technology, which is applied to mixer accessories, mixers with rotating stirring devices, products, etc., can solve the problems of inconvenient feeding, inconvenient collection, and inability to control the ratio of calcium carbonate and water, etc., to achieve convenient feeding , easy to collect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

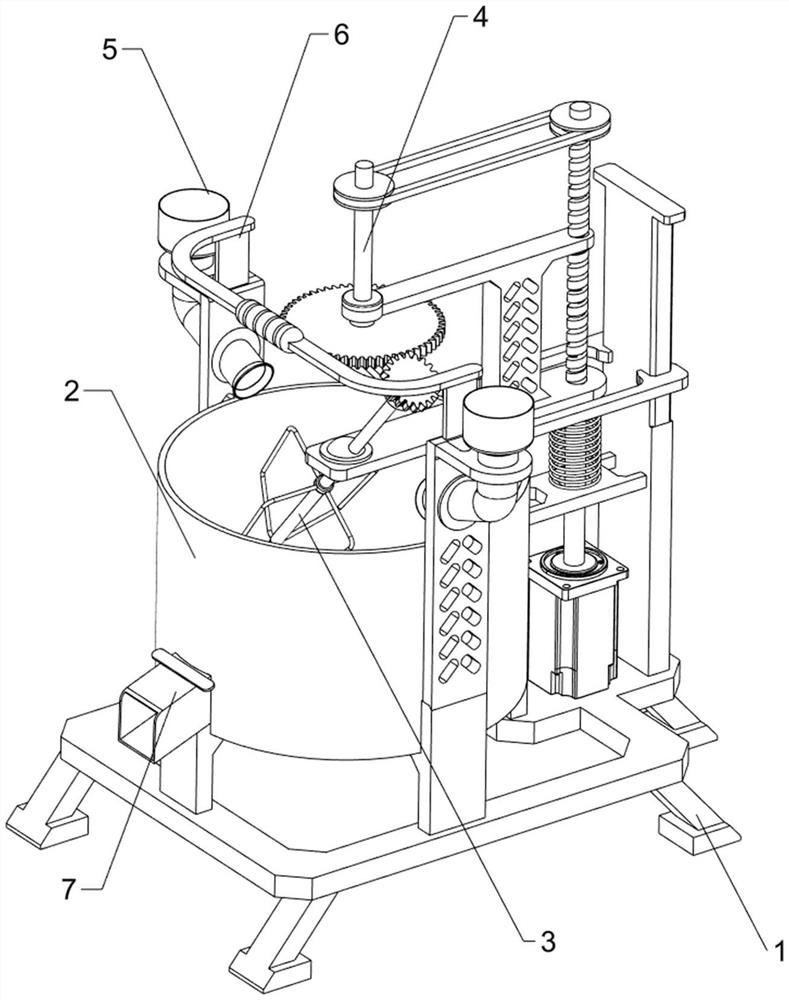

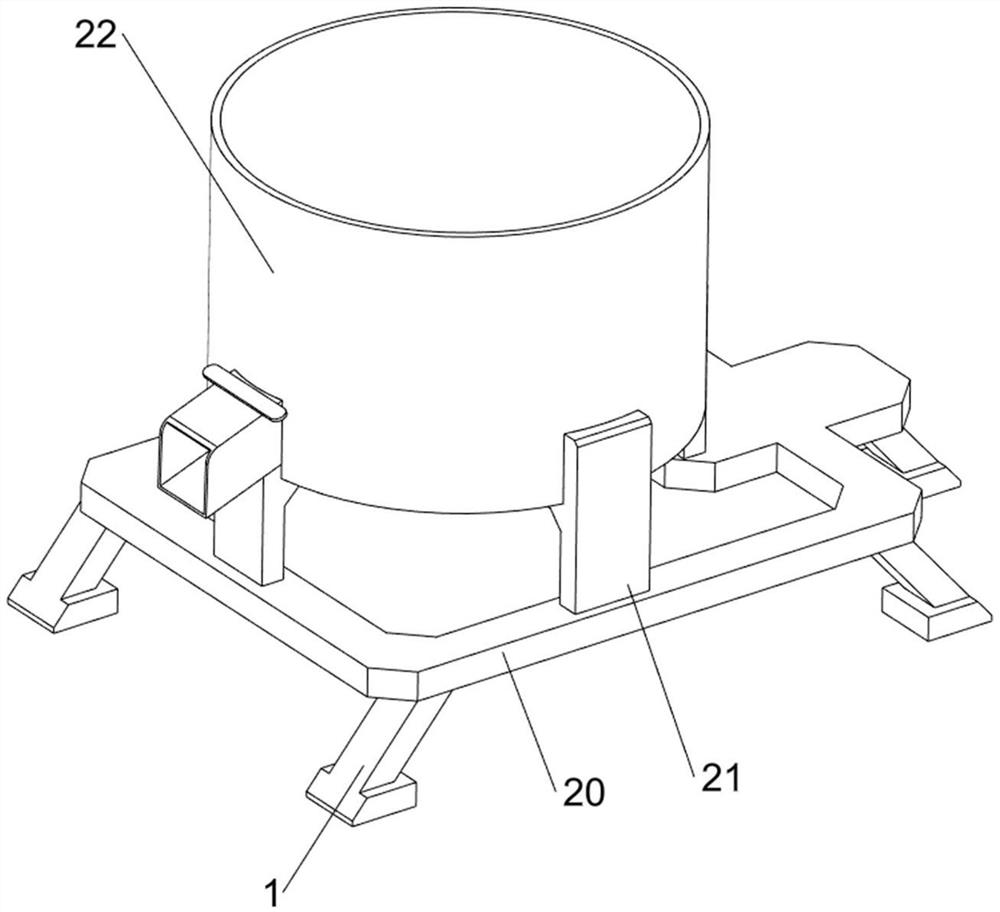

[0059] A kind of calcium carbonate liquid stirring equipment for calcium carbonate production, such as Figure 1-3 As shown, it includes a support 1, a holding mechanism 2 and a stirring mechanism 3. A holding mechanism 2 is arranged between the supports 1. There are five supports 1. A stirring mechanism 3 is placed in the holding mechanism 2.

[0060] When people need to stir the calcium carbonate liquid, this device can be used. First, people take out the stirring mechanism 3 from the holding mechanism 2, then put calcium carbonate and a certain amount of water into the holding mechanism 2, and then people Put the stirring mechanism 3 back in the holding mechanism 2, and then manually rotate the stirring mechanism 3, so that the stirring mechanism 3 fully stirs the calcium carbonate and water. After the calcium carbonate liquid is stirred, people stop rotating the stirring mechanism 3 and get final product.

[0061] The holding mechanism 2 includes a frame 20, a support rod ...

Embodiment 2

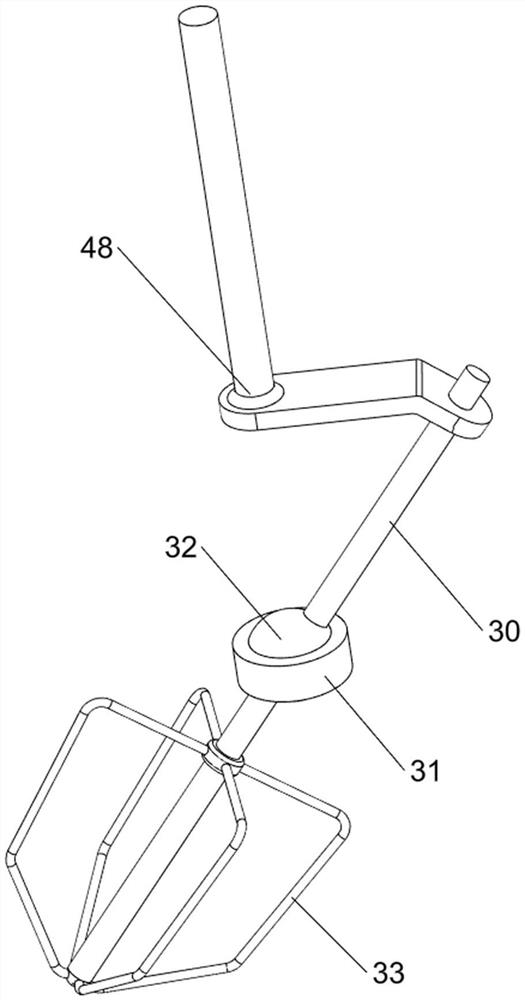

[0066] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 and Figure 6Shown, also comprise elevating mechanism 4, elevating mechanism 4 comprises servomotor 40, screw mandrel 41, guide rail 42, guide bar 43, first mounting base 44, fixed cover 45, first full gear 46, belt pulley group 47, rocker Rod 48, the second full gear 49, fixed seat 410 and spring 411, the right side of frame 20 top is provided with servo motor 40, and the output shaft of servo motor 40 is provided with screw mandrel 41, and frame 20 top right side is provided with guide rail 42 , slide type is provided with guide rod 43 on guide rail 42, and guide rod 43 is threadedly connected with screw mandrel 41, and guide rod 43 is connected with mounting sleeve 31, and the right side of guide rod 43 top is provided with first mounting base 44, and first mounting base 44 Threaded with the screw mandrel 41, the left side of the first mount 44 top is provided with a fixed sleeve 45, the fixed sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com