Double-component nozzle liquid flow performance testing device

A testing device and two-component technology, applied in the directions of injection device, measuring device, injection device, etc., can solve the problems that the dual-component nozzle cannot measure the flow rate at the same time, ablation, uneven distribution of the combustion flow field of the rocket engine, etc. Avoid uneven distribution of combustion flow field, high test efficiency, convenient and reliable measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

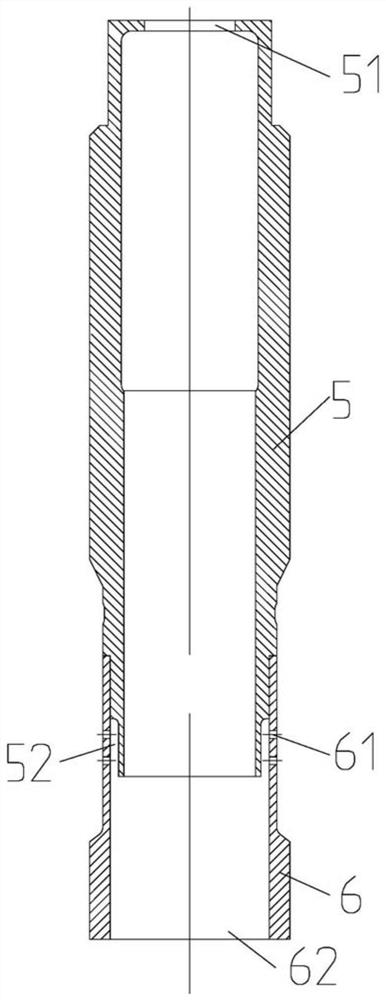

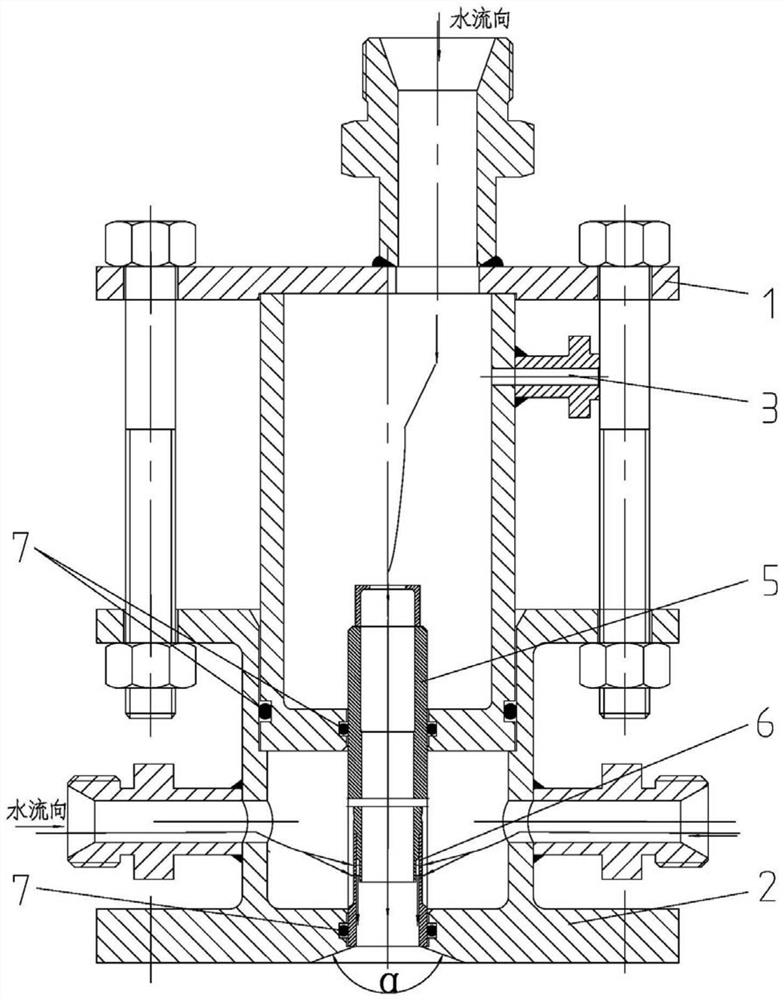

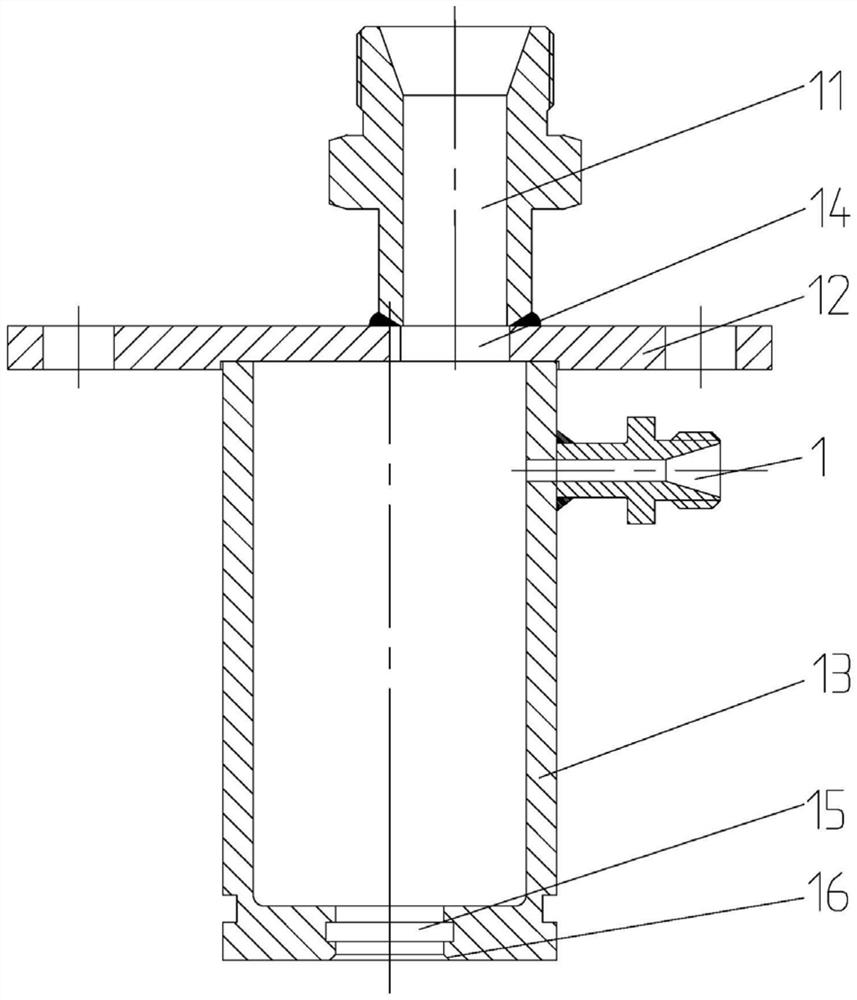

[0026] The invention provides a liquid flow performance testing device of a dual-component nozzle, which can obtain test data of the dual-component nozzle under the condition of two-way interference, and provide basis for model development. The dual-component nozzle liquid flow performance test device simultaneously measures the flow rate and spray angle of the nozzle in the two-way under a given pressure drop, and obtains the performance parameters under the condition of two-way coherence, and tests the water inlet of the upper shell and the lower shell The cavities are designed separately, and the water inlet chamber is arranged up and down. The simulated water inlet position corresponds to the actual water inlet and outlet positions of the product. At the same time, the water inlet nozzle and the pressure measuring nozzle are de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com