A kind of assembly method of evaporator liquid reservoir

An assembly method and technology of accumulator, which are applied in evaporator/condenser, biological packaging, refrigeration and liquefaction, etc., can solve the problems of unsatisfactory shape of welded part, affect the use effect, poor quality of welding seam, etc., and achieve optimized assembly method, easy welding, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

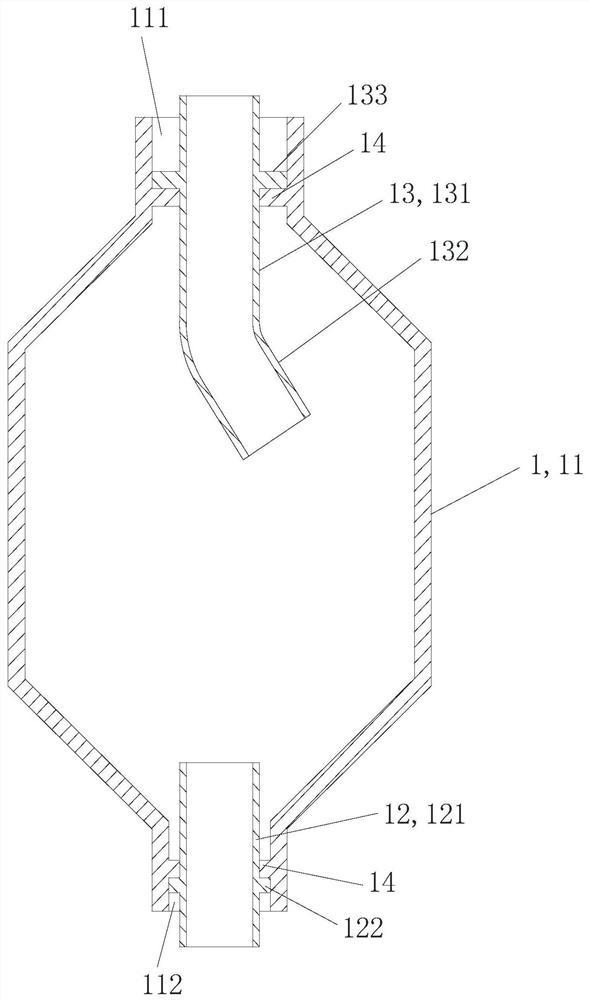

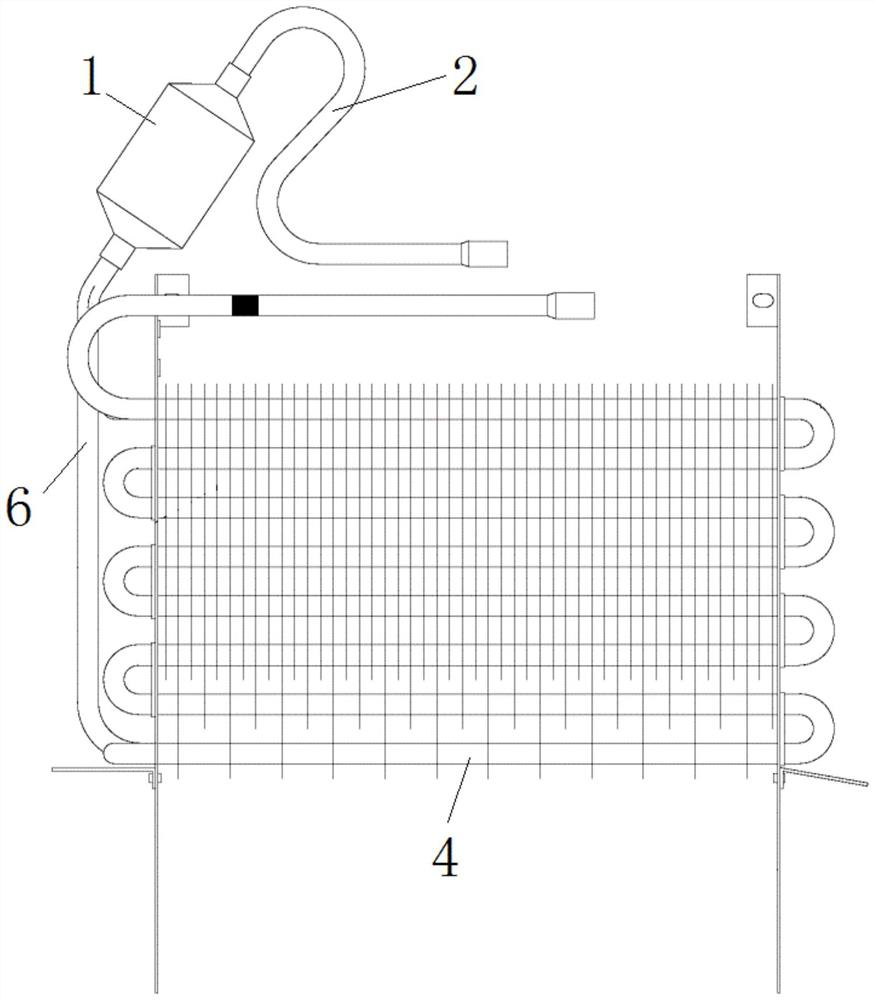

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] Such as Figure 1 to Figure 4 A liquid reservoir 1 of an evaporator includes a body 11, a first lining 12 and a second lining 13; the upper end of the body 11 is provided with an inlet 111, and the lower end is provided with an outlet 112, and the inner diameter of the inlet 111 is larger than that of the outlet 112 inner diameter. And the first liner 12 is arranged in the outlet 112, the second liner 13 is arranged in the inlet 111, and the inner wall of the body 11 is provided with a limit step 14 at the inlet 111 and the outlet 112; The piece 12 includes a first straight pipe 121 and a first stop ring 122 arranged on the outer wall 121 of the first straight pipe, and the first stop ring 122 abuts against the stop step 14 at the outlet; the second inner The liner 13 includes a connected second straight pipe 131 and a second bent pipe 132, and a second limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com