Parallel radial magneto-rheological valve and damper

A magneto-rheological valve, parallel technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problem of the reduction of the buffering efficiency of the magnetorheological damper, the small dynamic range of the magnetorheological damper, Problems such as impact load cannot be effectively alleviated to achieve the effect of improving controllability, increasing the range of damping force and dynamic range, and protecting life safety and equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

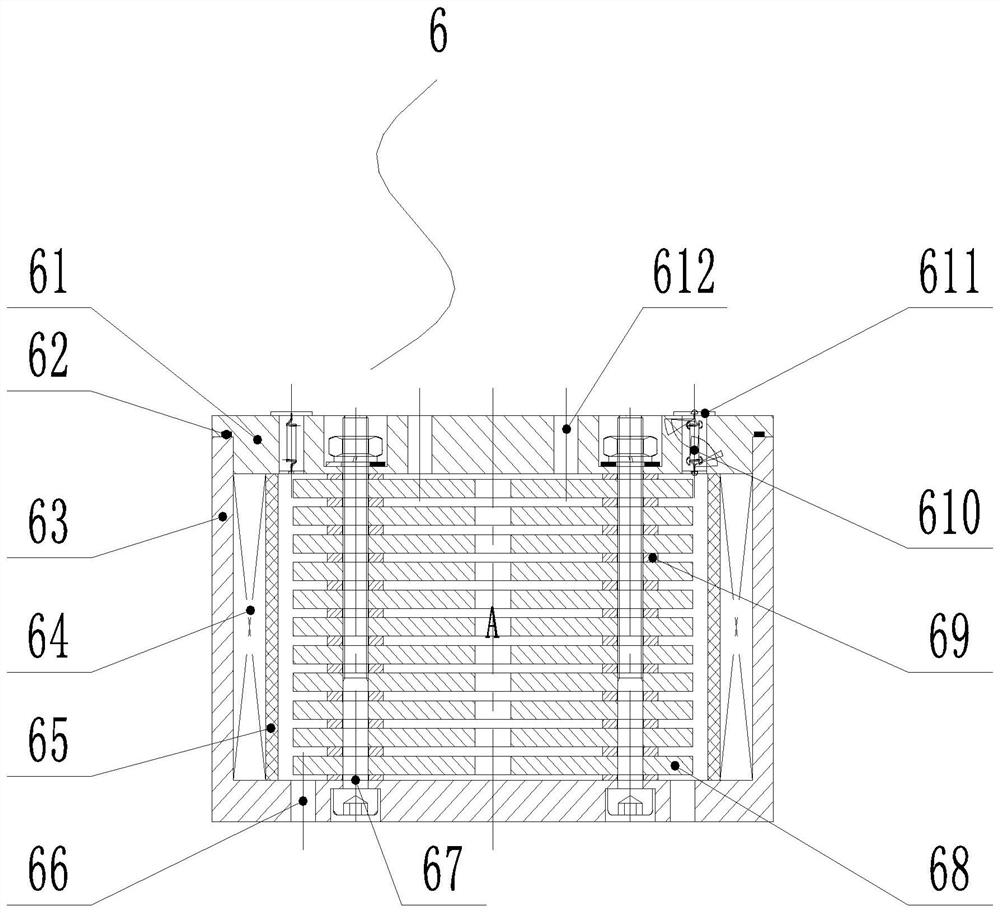

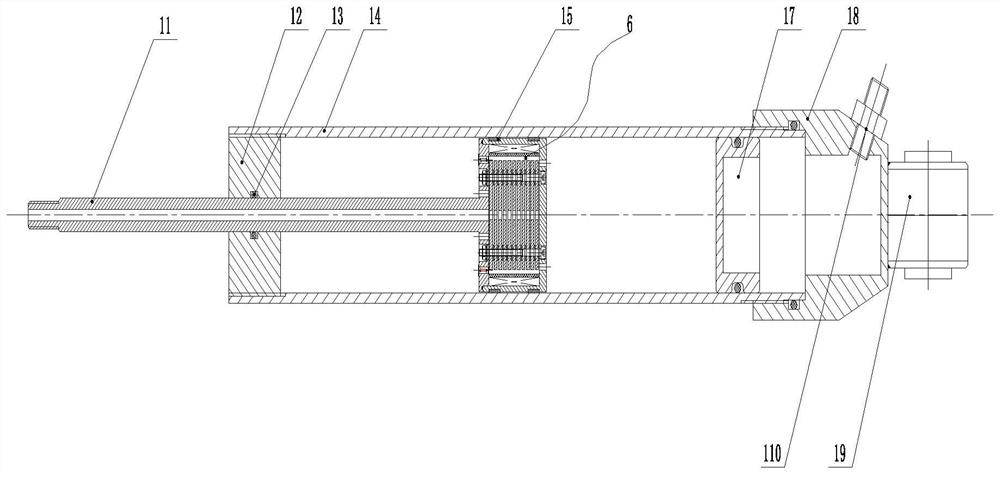

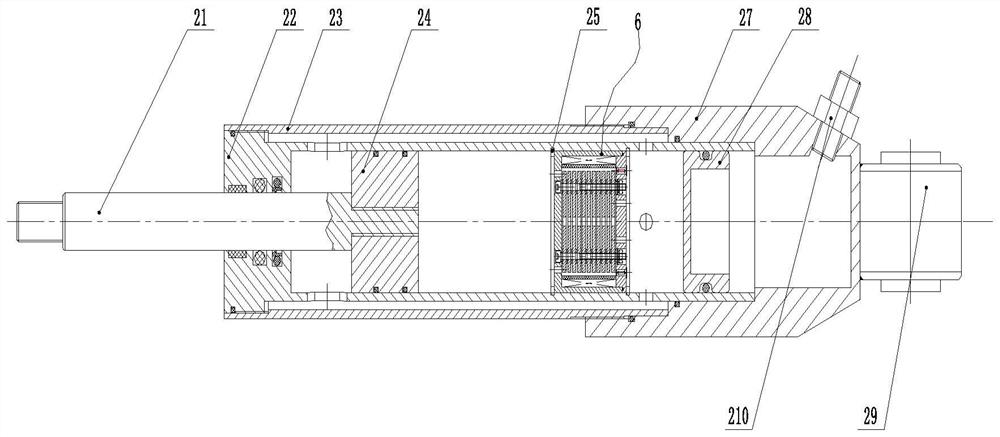

[0021] figure 1 It is a structural schematic diagram of a parallel radial magneto-rheological valve of the present invention; figure 2 It is a structural schematic diagram of the first shock absorber of the present invention; image 3 It is a structural schematic diagram of the second shock absorber of the present invention; Figure 4 It is a structural schematic diagram of the third shock absorber of the present invention; as shown in the figure, a parallel radial magneto-rheological valve 6 includes a piston outer cylinder 63 and a piston upper end cover 61 arranged at the end of the piston outer cylinder 63, and the upper end cover A sealing ring 62 is also provided between 61 and the piston outer cylinder 63, and an O-shaped sealing ring 62 is used to ensure a good internal sealing effect; the piston outer cylinder 63 is evenly spaced with a plurality of magnetic plates 68 along the axial direction, so A coil spacer 65 is arranged between the magnetically conductive she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com