A drive shaft with a dust-proof oil seal structure

A technology for transmission shaft and dust-proof oil, applied in the field of auto parts, can solve the problems of reducing the sealing performance of the oil seal, failing to maintain the sealing performance of the oil seal, and degeneration and damage of the oil seal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

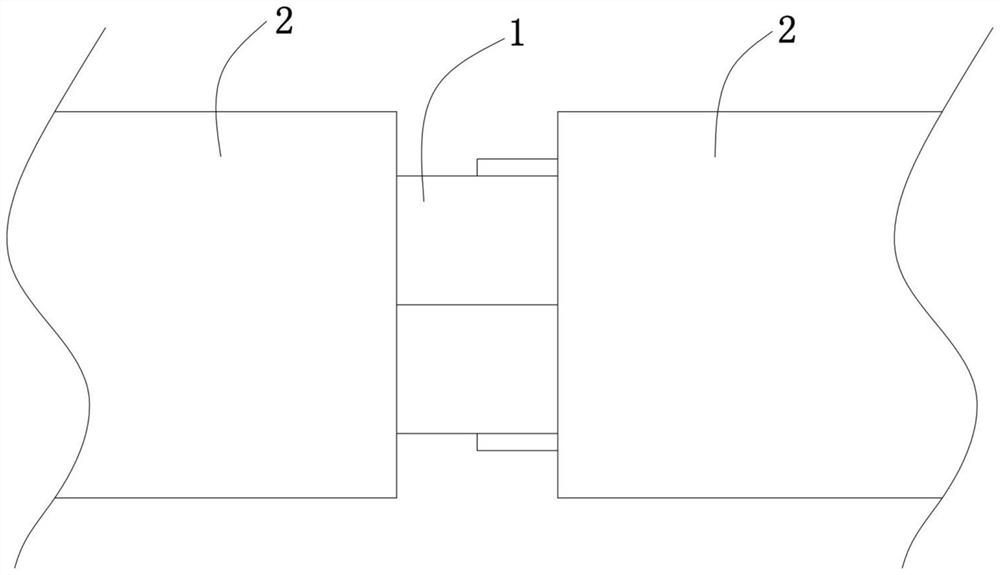

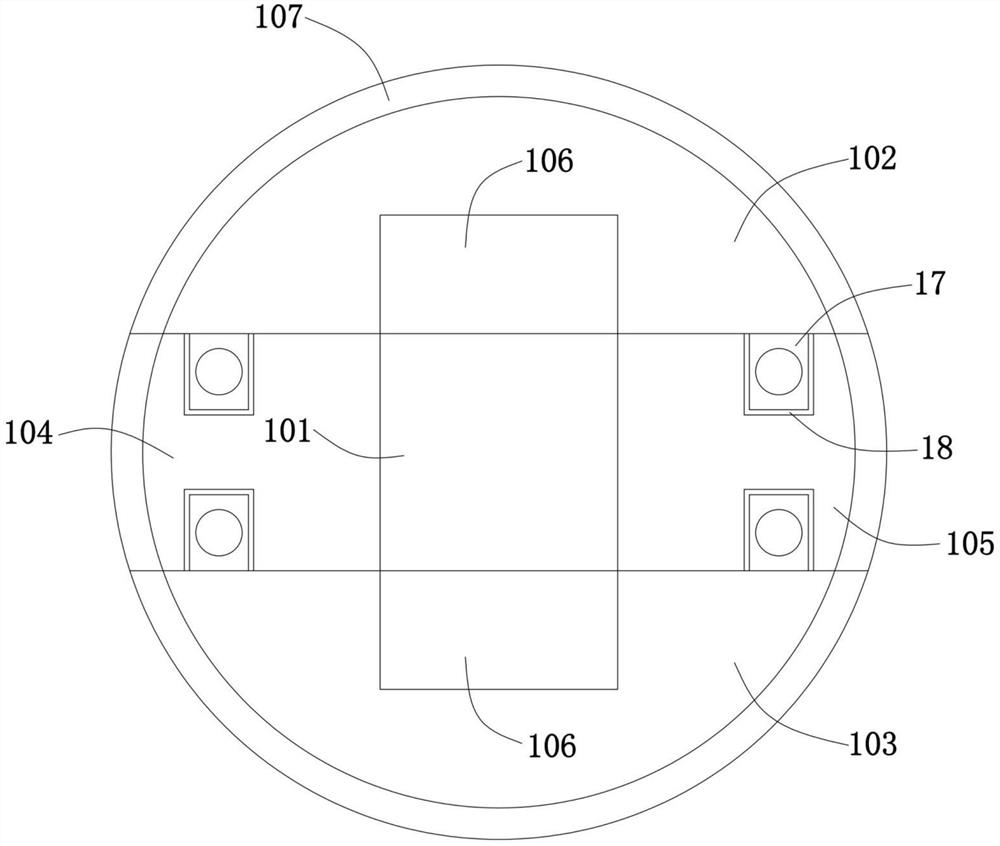

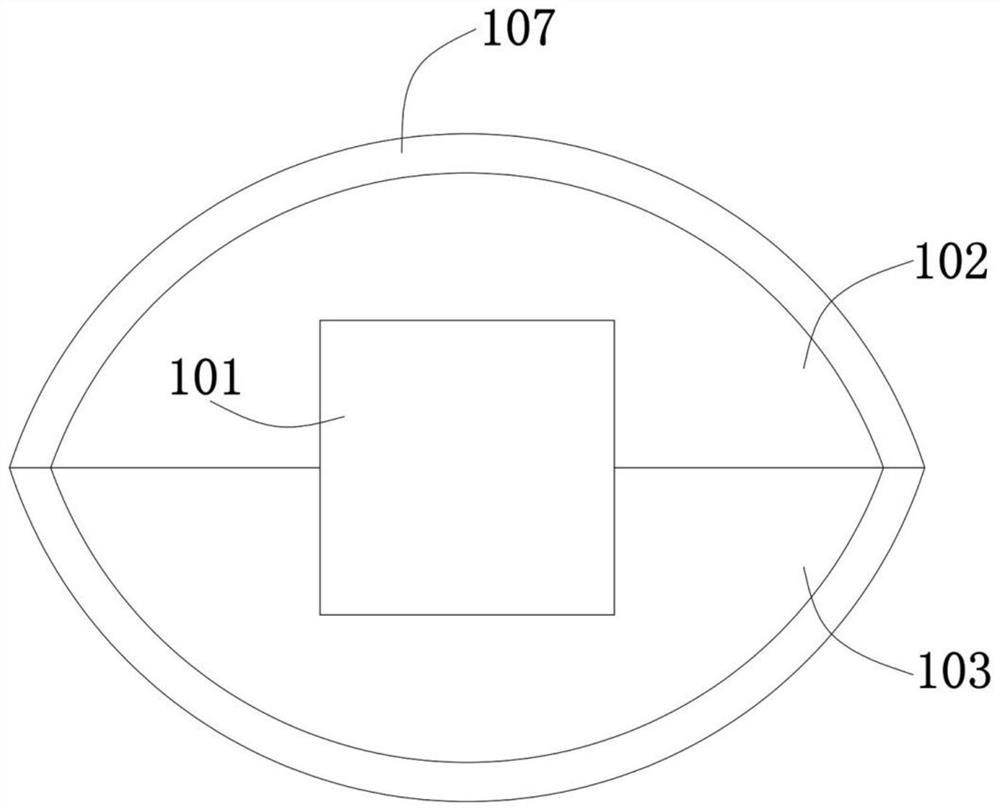

[0035] Such as Figure 1 to Figure 5As shown, a transmission shaft with a dust-proof oil seal 3 structure, which includes a central shaft 1, and a main shaft 2 with an outer diameter smaller than the central shaft 1, which is arranged on both sides of the central shaft 1, and the central shaft 1 includes a transmission mechanism for driving The driving mechanism of the transmission mechanism and the connecting part 101 integrally formed with the main shaft 2 on both sides are slidably installed between the main shafts 2 and symmetrically arranged on the first arc-shaped block 102 and the second arc-shaped block 103 at the upper and lower ends of the connecting part 101 , the first movable piece 104 and the second movable piece 105 that are located at the left and right ends of the connecting portion 101, the connecting portion 101 is provided with a driving chamber 101a, and the driving mechanism is installed in the driving chamber 101a and is connected to the first arc-shaped ...

Embodiment 2

[0046] Such as Figure 7 and Figure 9 As shown, in this embodiment, one of the optimized designs is made on the basis of the above-mentioned embodiment 1. A torsion spring 15 is fixed on the first movable block 104 on the side of the guide plate 14, and any force arm of the torsion spring 15 is fixed. There is a baffle plate 16, and the baffle plate 16 is fixed with the guide plate 14 at the same time. When the first movable block 104 and the second movable block 105 are separated from the slot 201, the torsion spring 15 restores the deformation to drive the baffle plate 16, and the baffle plate 16 drives the guide plate 14 to move toward the step, so that the step can abut against the guide plate 14 again, preventing the first movable block 104 and the second movable block 105 from shifting.

Embodiment 3

[0048] Such as figure 2 As shown, the present embodiment makes one of the optimized designs on the basis of the above-mentioned embodiment 1, the first arc-shaped block 102 and the second arc-shaped block 103 are formed with clamping plates 17, the first movable block 104 and the second The movable block 105 is provided with a draw-in groove 18 that can be engaged with the clamp plate 17, and the clamp plate 17 and the draw-in groove 18 are provided with corresponding screw holes. After the oil seal 3 is installed, the first arc-shaped block 102, The second arc-shaped block 103 , the first movable block 104 and the second movable block 105 are fixed to each other, thereby avoiding relative movement and affecting the oil sealing effect of the oil seal 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com