Pulse jet damping and depressurizing device and using method

A depressurization device and pulse jet technology, applied in drilling equipment and methods, earthwork drilling, drilling with liquid/gas jets, etc., can solve the problems of low efficiency, narrow safe density window, high working cost, etc., to reduce production The effect of reducing costs, saving operating time, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

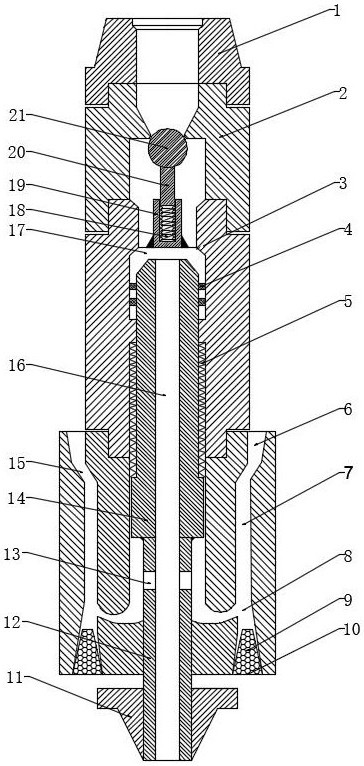

[0022] In order to overcome the problems of high working cost and low efficiency caused by the narrow safe density window of the existing deepwater drilling fluid, the present invention provides a pulse jet shock absorbing and pressure reducing device and its use method. The present invention can absorb the mechanical energy generated by the vibration of the drill string, and then The mechanical energy is converted into hydraulic energy to provide greater pressure for the jet hole, thereby generating greater negative pressure, and finally accelerate the upward return of annular drilling fluid, thereby achieving the purpose of reducing pressure. The invention reduces the annular space pressure, prevents the occurrence of leakage, and makes drilling safe and efficient.

[0023] A pulse jet shock-absorbing and pressure-reducing device, comprising an upper joint 1, an outer cylinder 3, a pressurizing rod 12, a piston 14, a movable sealing device, an injection mechanism and a lower ...

Embodiment 2

[0029] Based on Embodiment 1, in this embodiment, preferably, the lower end of the upper joint 1 and the lower end of the check valve assembly 2 are threaded; the lower joint 11 and the pressure rod 12 are threaded.

[0030]The device is connected to both ends of the drill pipe through a male buckle and a female mouth. The lower end (female thread) of the upper joint 1 is threadedly connected with the upper end (male thread) of the check valve assembly 2 ; the lower joint 11 and the pressure rod 12 are threadedly connected.

[0031] Preferably, the check valve assembly 2 includes a check valve body, a valve seat 19, a spring 18, a valve stem 20 and a valve ball 21, the upper end of the check valve body has a tapered hole, and the check valve The lower end of the body has an inner stepped hole, and the valve ball 21 is located in the inner stepped hole, and the diameter of the valve ball 21 is larger than the minimum inner diameter of the tapered hole; the lower end of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com