Automatic cap-pressing residue-removing wine fermentation tank

A technology for slag wine and fermentation tank, which is applied in the field of automatic cap-pressing and slag removal wine fermentation tank, and can solve the problems of difficult operation, high labor intensity of slag removal, and difficult control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

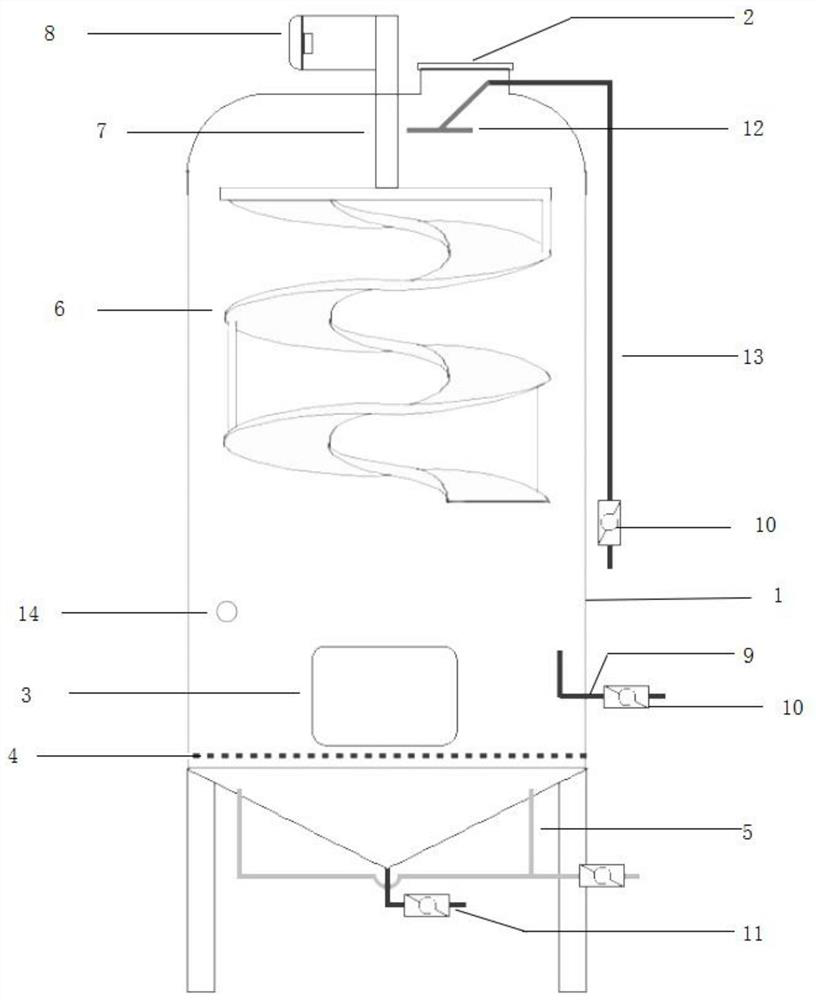

[0020] refer to figure 1 , the present embodiment provides a wine fermentation tank with automatic capping and deslagging, comprising a tank body 1, an upper manhole 2 and a lower manhole 3 are opened on the upper end and the lower side of the tank body 1, and the lower manhole 3 is located inside the tank body 1. 3 is horizontally provided with a sieve plate 4, the bottom of the tank body 1 is connected with a backwash pipe 5, and the upper part of the tank body 1 is also vertically rotated with a spiral blade 6, and the outer diameter of the spiral blade 6 is smaller than that of the tank body. The inner diameter of the body 1 is 10 cm smaller, and the middle part of the upper end of the helical blade 6 is fixedly connected with a telescopic rod 7 arranged vertically. The telescopic rod 7 is an electrically controlled telescopic rod, preferably an anti-twist electronically controlled telescopic rod. Body 1 and stretches out to the top of tank body 1, and the top of tank body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com