Motor caravan forehead and carriage staggered lap joint structure and assembling method

A caravan and joint structure technology, which is applied to the superstructure, the connection between superstructure subassemblies, vehicle components, etc., can solve problems such as sealant failure at lap joints, uneven roof outer guards, and water leakage in the compartment , to achieve the effect of eliminating water accumulation, improving reliability and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

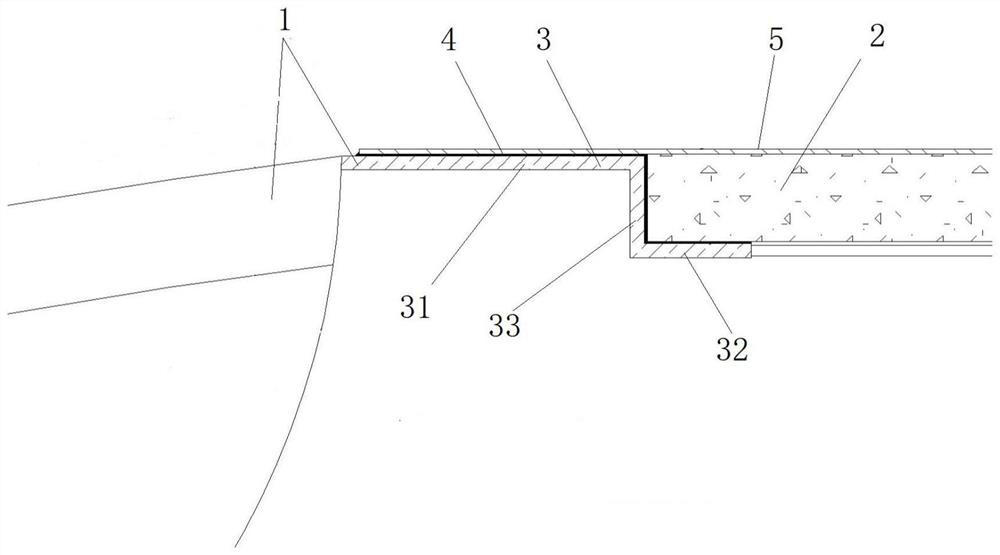

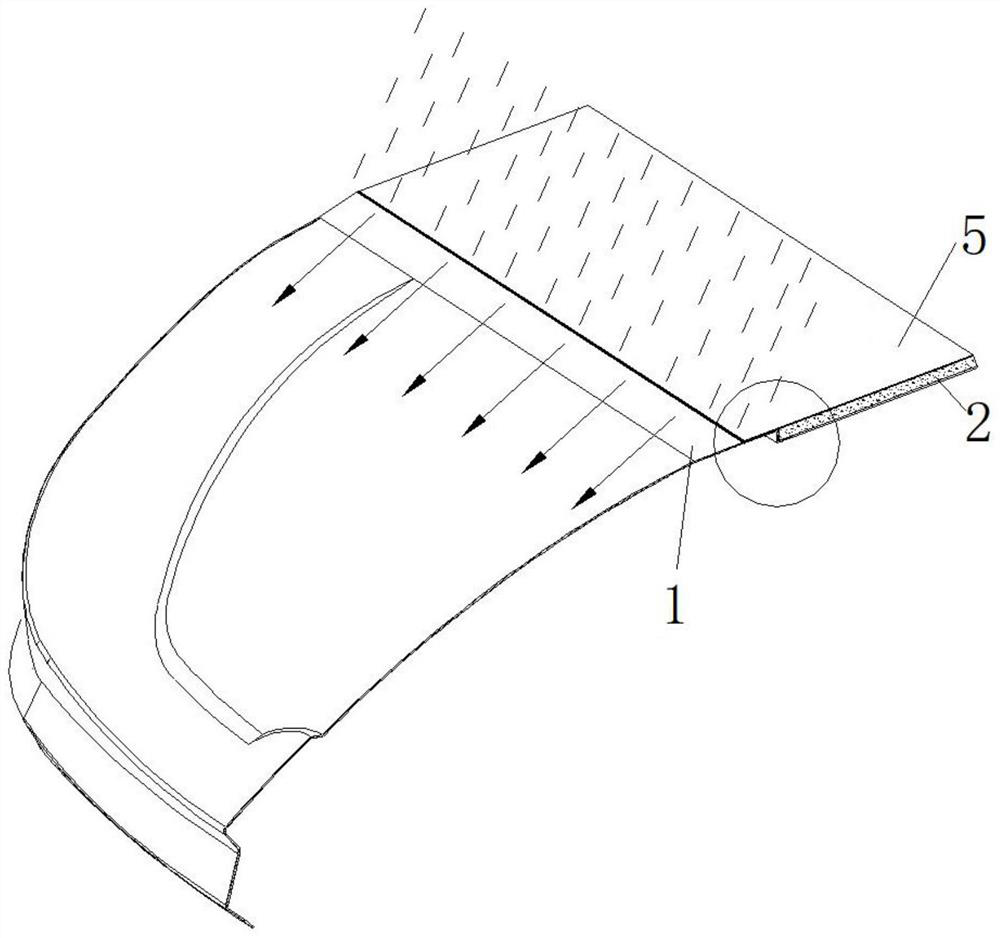

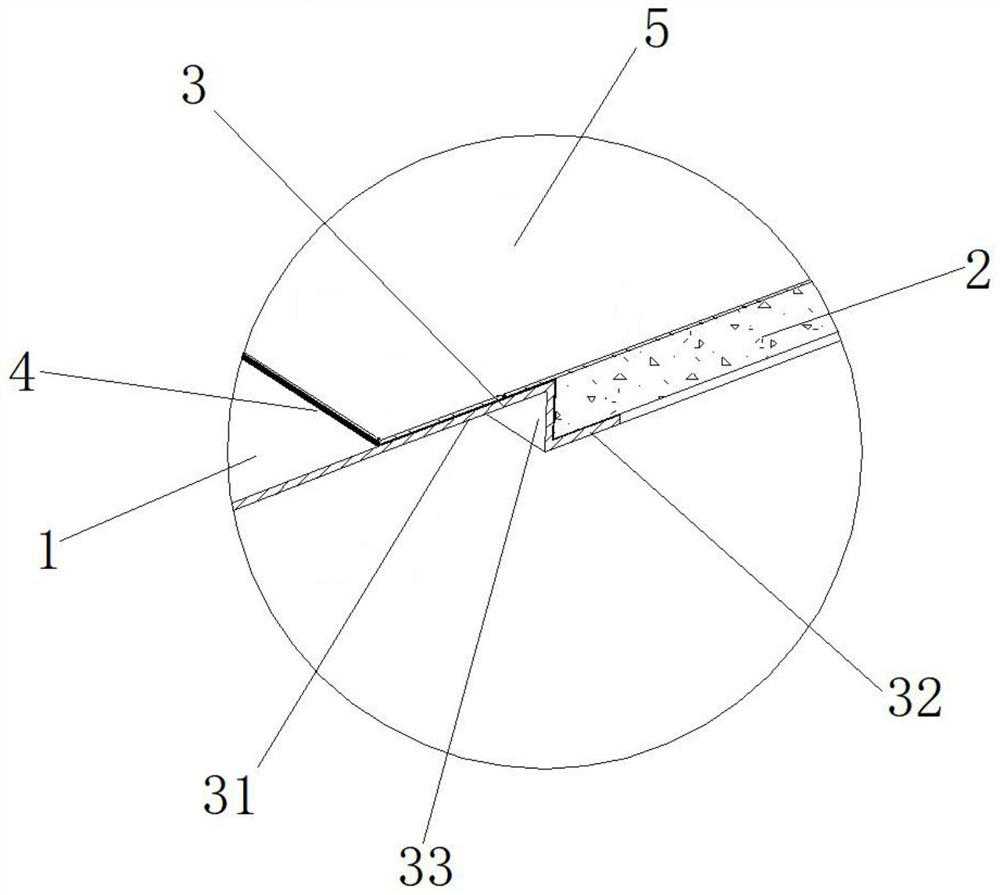

[0028] like figure 1 As shown, a caravan with a forehead and a car body split-level overlapping structure, including a forehead 1 and a car body roof 2, the forehead 1 is provided with a bending plate 3 at the junction of the forehead 1 and the car body roof 2, and the bending plate 3 includes The first connecting plate 31 and the second connecting plate 32 parallel to each other are connected by the third connecting plate 33 between the first connecting plate 31 and the second connecting plate 32, the first connecting plate 31, the third connecting plate 33, the second connecting plate 31 The connecting plates 32 are sequentially connected to form a stepped structure, the first connecting plate 31 is located above the second connecting plate 32, the second connecting plate 32 and the third connecting plate 33 form an L-shaped structure, and the top plate 2 of the car body is arranged on the top plate through the sealant 4. In the L-shaped cavity of the L-shaped structure, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com