Production device and process for recycling, granulating and reusing high-quality bottle flakes

A technology of production equipment and production process, which is applied in the field of production equipment for high-quality bottle flake recycling, granulation and reuse, which can solve the problems of unequal pellet weight, substandard, uneven dyeing, etc., to achieve uniform product quality and improve production High efficiency and high degree of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

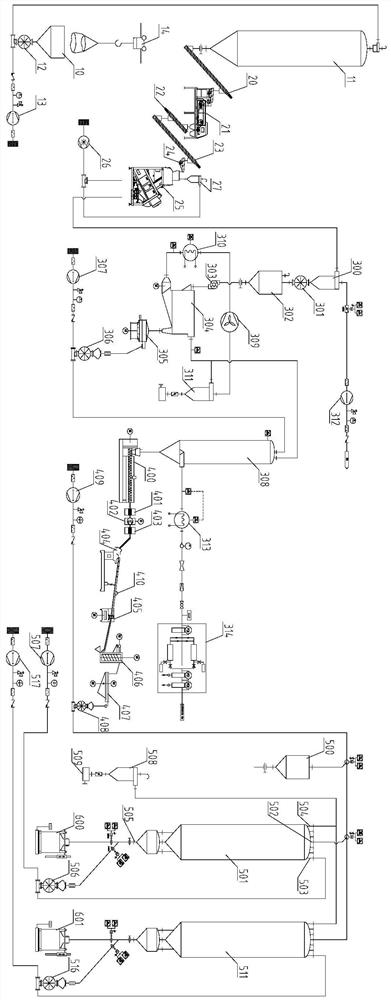

[0043] Example: such as figure 1 As shown, a production device for recycling, granulating and reusing high-quality bottle flakes, including a bottle flake feeding device, an impurity removal and drying device, a screw extrusion pelletizing device and a multi-silo mixing device,

[0044] Wherein the bottle flake feeding device mainly comprises a bottle flake feeding hopper 10 and a bottle flake storage bin 11, the outlet of the bottle flake feeding hopper communicates with the inlet of the bottle flake storage bin through a material pipeline, and the discharge of the bottle flake feeding hopper The material pipeline at the mouth is provided with a first rotary valve 12 and a first conveying fan 13,

[0045] The impurity removal and drying device includes an eddy current sorter 21, a material sorter 25, a fluidized bed 304, a circular vibrating screen 305 and a drying reaction tower 308 arranged in sequence, wherein, at the outlet of the bottle flake storage bin 11 A first scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com