High-temperature alloy complex thin-walled workpiece casting system

A pouring system and high-temperature alloy technology, applied in the field of alloy investment casting, can solve the problems of difficult casting process, difficult forming of thin-walled parts, large alloy paste area, etc. Good effect, the effect of improving casting qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

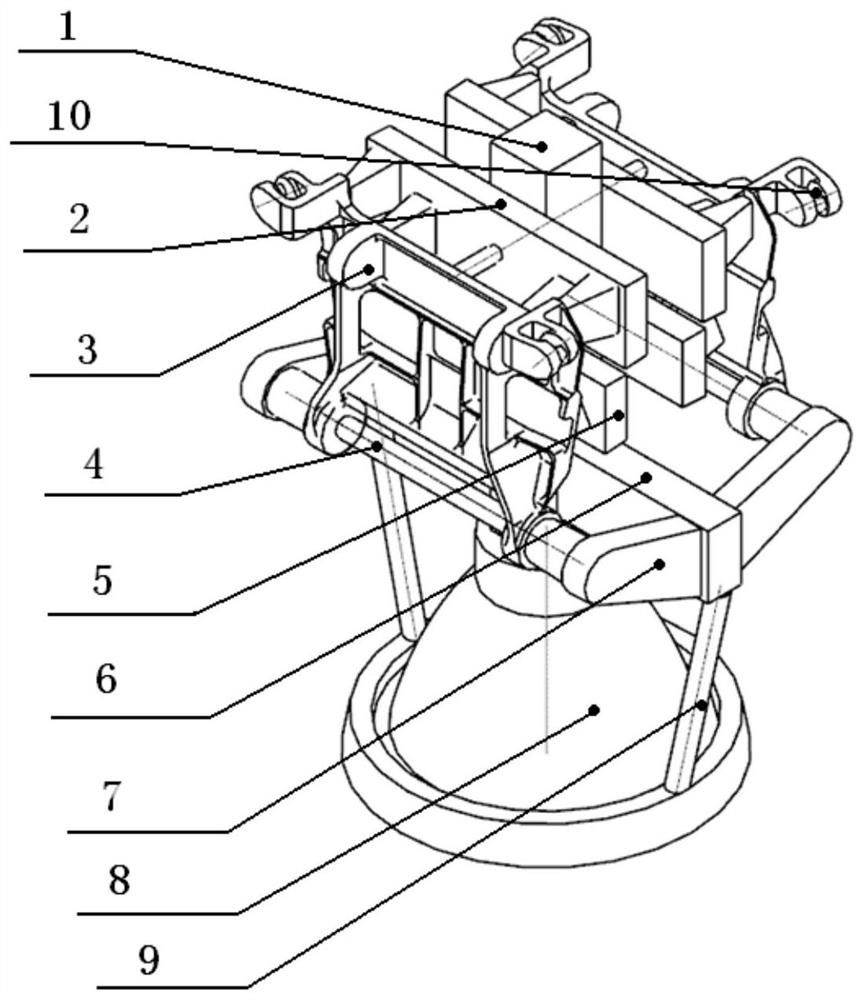

[0031] like figure 2 As shown, a high-temperature alloy complex thin-walled gating system, the gating system is a set of two-piece mold:

[0032] The pouring system is provided with a basic pouring unit, a sprue cup 8 and an exhaust channel 9, and the basic pouring unit is composed of a sprue 1, a runner A2, a runner B5, a runner C6, a runner D7, Composed of anti-deformation rod M4 and anti-deformation rod N10, the specific structure of the gating system is as follows:

[0033] The basic pouring unit structure is that two runners C6 are symmetrically arranged on the left and right sides of the bottom of the sprue 1, and two runners B5 and two runners A2 are symmetrically arranged on the front and rear sides of the sprue 1 in sequence, and The runner A2 is located below the runner B5, a pair of runners D7 are arranged symmetrically at the outer ends of the front and rear sides of the runner C6, and the anti-deformation rod M4 is arranged between the two front pin hole seats 3...

Embodiment 2

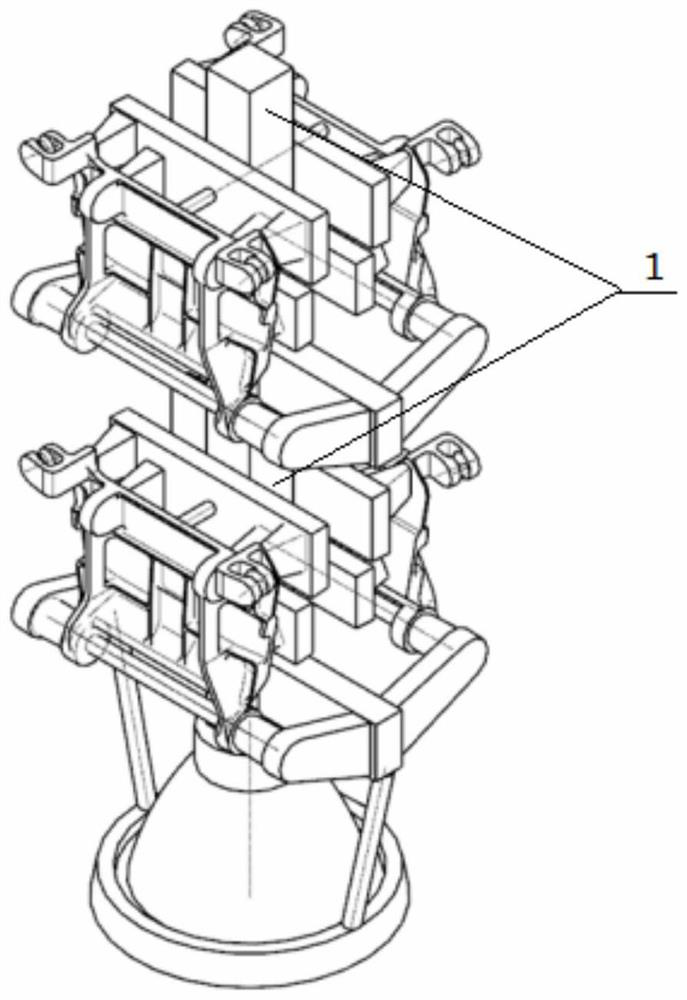

[0044] like image 3 As shown, a high-temperature alloy complex thin-walled gating system, the gating system is a set of four-piece mold:

[0045] The pouring system is provided with two basic pouring units, a sprue cup 8 and an exhaust channel 9. The basic pouring unit consists of a sprue 1, a runner A2, a runner B5, a runner C6, and a runner D7, anti-deformation rod M4, anti-deformation rod N10, the specific structure of the pouring system is as follows:

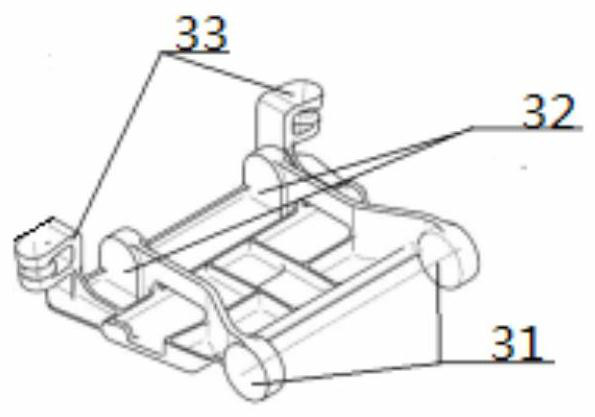

[0046] The basic pouring unit structure is that two runners C6 are symmetrically arranged on the left and right sides of the bottom of the sprue 1, and two runners B5 and two runners A2 are symmetrically arranged on the front and rear sides of the sprue 1 in sequence, and The runner A2 is located below the runner B5, a pair of runners D7 are arranged symmetrically at the outer ends of the front and rear sides of the runner C6, and the anti-deformation rod M4 is arranged between the two front pin hole seats 31 of the wax m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com