Chemical experiment test stand facilitating vessel cleaning and using method thereof

A technology of chemical experiments and test benches, applied in the field of chemical experiments, can solve the problems of wasting water resources, time-consuming and labor-intensive, etc., and achieve the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

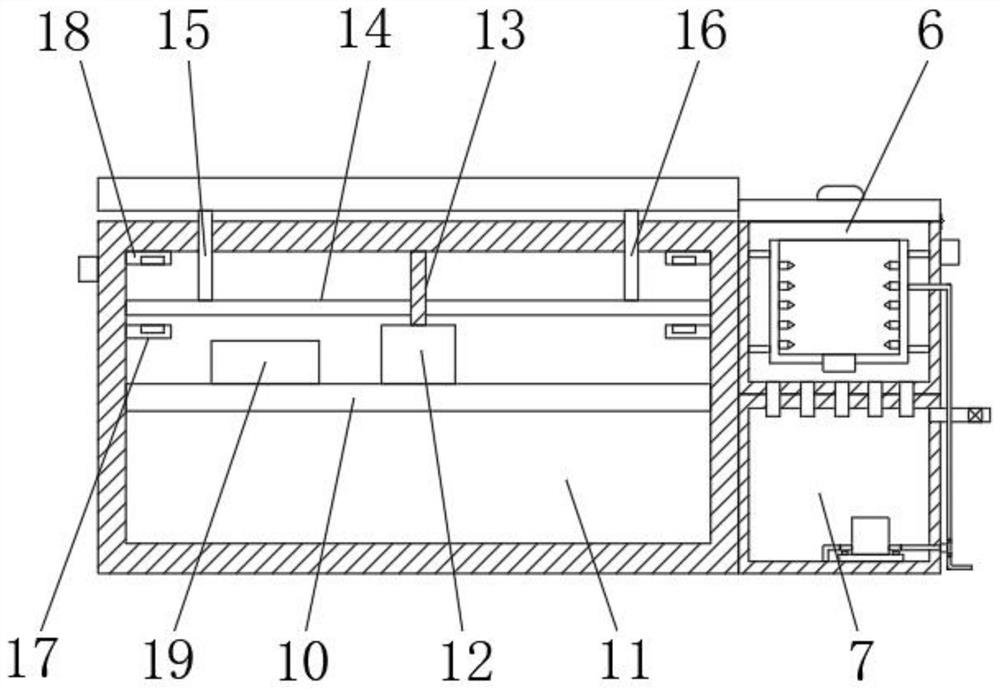

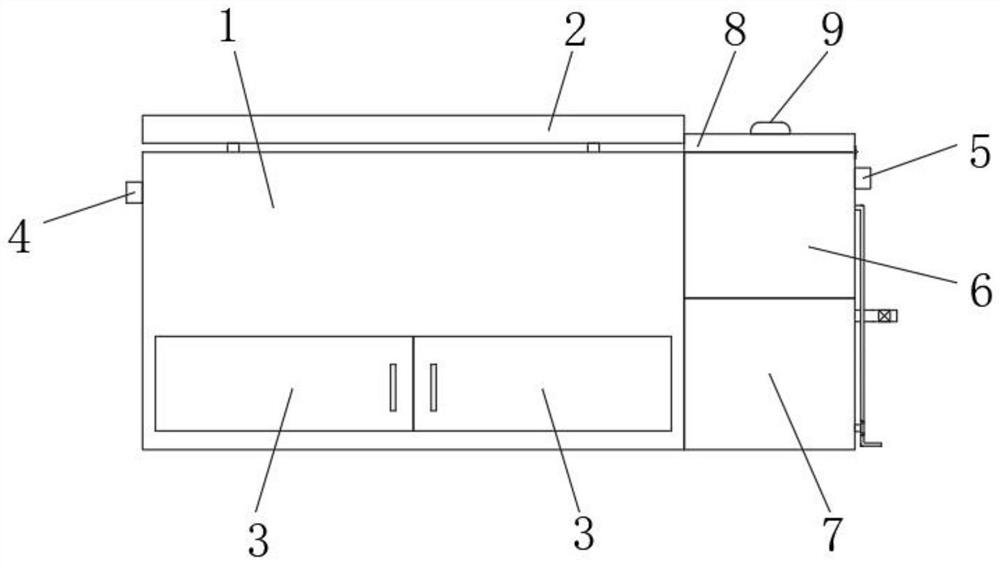

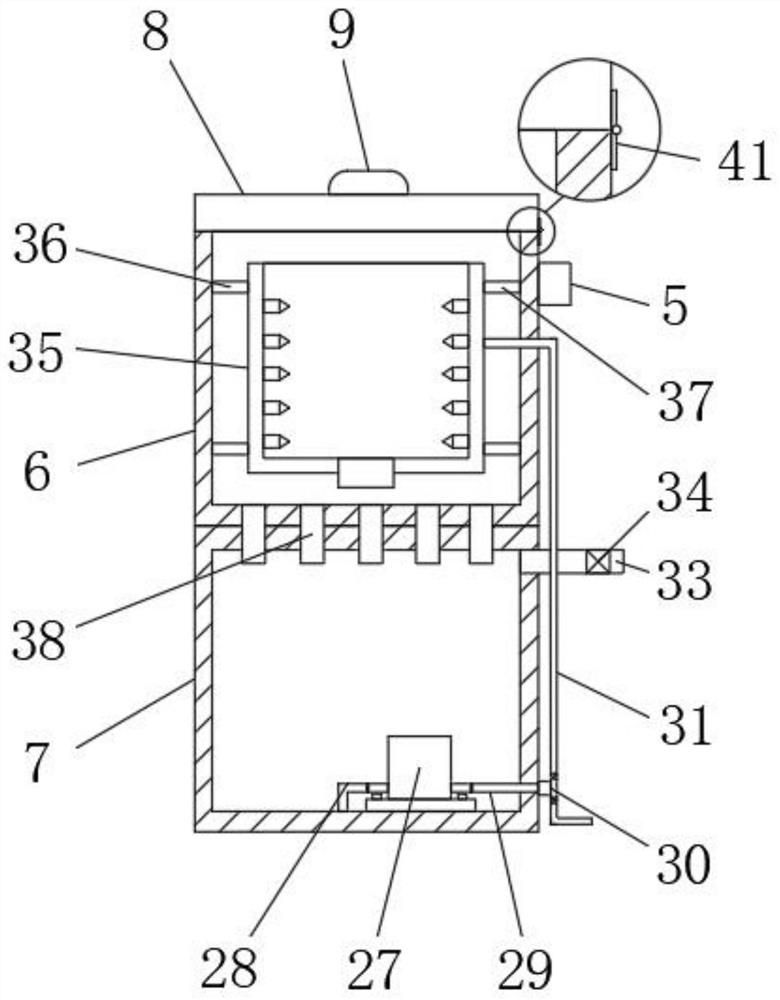

[0054] see Figure 1-Figure 11 , the present invention provides a technical solution:

[0055] A test bench for chemical experiments that is convenient for cleaning utensils, comprising: an experimental box 1, an experimental platform 2 is arranged above the experimental box 1, a water tank 7 is welded to the lower part of the outer wall of the experimental box 1, and the experimental box The outer wall of 1 is located at the top of the water tank 7 and is welded with a cleaning box 6. The bottom side of the inner cavity of the water tank 7 is screwed with a submersible pump 27. The inner cavity of the cleaning box 6 is provided with a vessel cleaning tank 35. The inner wall of the cleaning box 6 The upper and lower parts of one side are welded with a third pole 36 horizontally, and the cleaning box 6 is welded with a fourth pole 37 with respect to the upper and lower parts of the inner wall of one side of the third pole 36. The third pole 36 One end of each end is welded wit...

Embodiment 2

[0084] S1. The user opens the box cover 8 by pulling the handle 9 under the action of the hinge 41, and places the chemical experiment utensils in the utensil cleaning tank 35. After all the placement is completed, the box cover 8 is closed for Prevent water from splashing when cleaning;

[0085] S2, the single-chip microcomputer 21 is set by the computer, so that the working time of the single-chip microcomputer 21 to control the submersible pump 27 is 5 minutes, and the working intensity is a normal mode;

[0086] S3, open the water injection valve 34, add water to the water tank 7 through the water injection port 33, close the water injection valve 34 after the filling is completed, open the valve at the place where the three-way valve 30 is connected with the third water pipe 31, and close the three-way valve. The through valve 30 is a valve communicating with the drain pipe 32;

[0087] S4. Press the second switch 5 to start the submersible pump 27 under the control of t...

Embodiment 3

[0092] S1. The user opens the box cover 8 by pulling the handle 9 under the action of the hinge 41, and places the chemical experiment utensils in the utensil cleaning tank 35. After all the placement is completed, the box cover 8 is closed for Prevent water from splashing when cleaning;

[0093] S2, the single-chip microcomputer 21 is set by the computer, so that the working time of the single-chip microcomputer 21 to control the submersible pump 27 is 4 minutes, and the working intensity is a normal mode;

[0094]S3, open the water injection valve 34, add water to the water tank 7 through the water injection port 33, close the water injection valve 34 after the filling is completed, open the valve at the place where the three-way valve 30 is connected with the third water pipe 31, and close the three-way valve. The through valve 30 is a valve communicating with the drain pipe 32;

[0095] S4. Press the second switch 5 to start the submersible pump 27 under the control of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com