Municipal garbage solid-liquid separation device

A technology for solid-liquid separation and municipal waste, which is applied in filtration separation, separation methods, metal processing, etc., can solve the problems of inconvenient waste disposal, unsatisfactory separation effect, single operation method, etc., to increase the up and down reciprocating vibration and ensure solid-liquid The effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

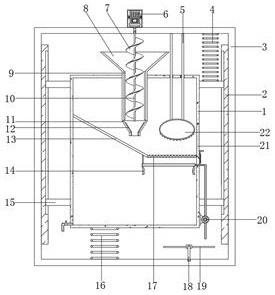

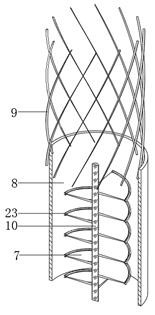

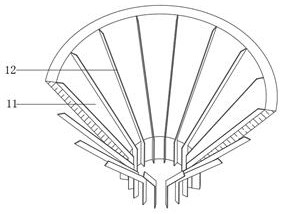

[0029] Refer Figure 1-4 , A municipal land-solid solution, including separation tank 1, and the outer wall of the separation tank 1 is provided with an outer fixing frame 3, and both sides of the outer fixing frame 3 are fixedly mounted, and the rail 2 is mounted, and the inner wall of the guide rail 2 is slid. The end portion of the slider 15 is connected to the separation tank 1, and the top end of the separation tank 1 is welded with the tower 8, and the bottom end welding of the purse 8 is welded to the bodies 11, the tuning 8 and the fight The inner wall of the outer housing end 11 is fixedly mounted, respectively, the spiral wall knife 9 and the straight knife 12 are fixed, and the top outer wall of the outer fixing frame 3 secure the rotary electric machine 6, and the output shaft of the rotary motor 6 is passed through the coupling. The outer wall of the transfer column 10 is connected, and the mounting of the mounting blade 7 is fixedly mounted, and the edge of the strap ...

Embodiment 2

[0038] Refer figure 1 with Figure 5 , A municipal waste solid solution separation device, which is also attached to the first end of the inner bottom portion of the outer fixing frame 3, which is also attached to the embodiment.

[0039] In the present invention, the anti-winding mechanism includes rotation of the rotary rod 18 connected to the outer fixing frame 3, and the top end of the rotary rod 18 is rotatably coupled to the winding 19, and the top outer wall of the wind pad 19 is fixedly mounted with a top arc plate 25; The arrangement of the air mechanism is used to block the output of the pump 20 by the winding 19, the top arc plate 25 is blocked, so that the extra gas pump 20 can be protected by reaction.

[0040] Among them, the specifications of the top arc plate 25 are different, and the top outer wall of the top arc plate 25 is fixedly mounted, and the air-shaped-distributed air-blown strip 26 is mounted; the air-blown strip 26 mates the air flow output by the pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com