Textile dye filtering and recycling treatment method

A technology of textile dyes and treatment methods, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of textile waste discarding, affecting filtration efficiency, wasting costs, etc., to avoid waste, save costs, and increase work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

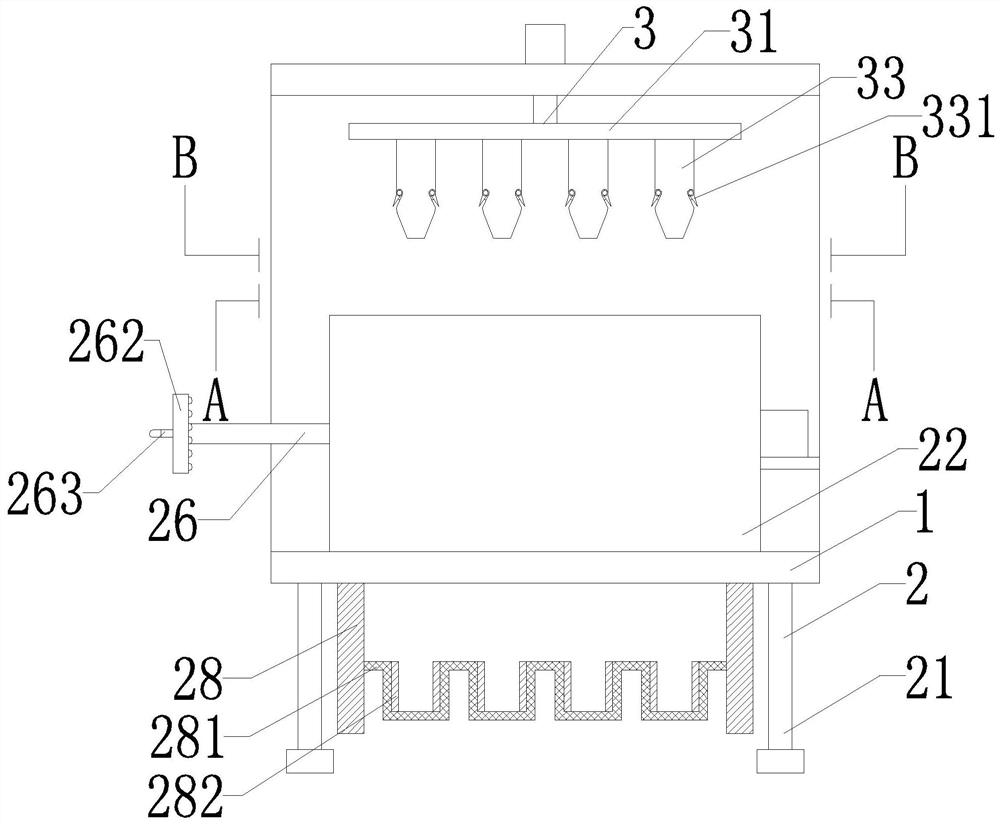

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

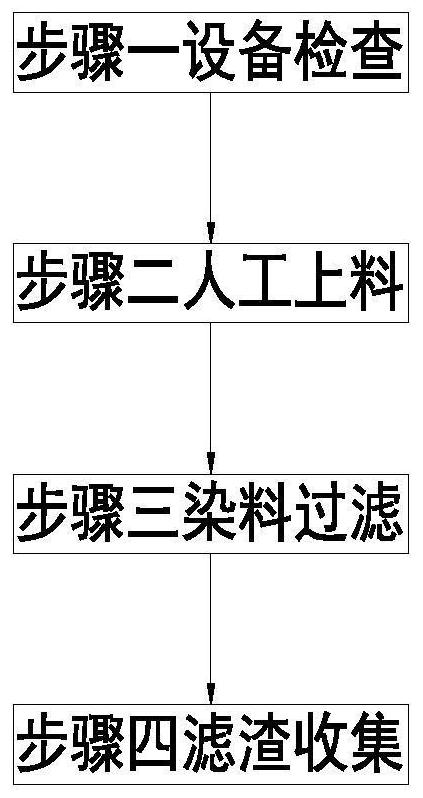

[0032] Such as Figure 1 to Figure 8 Shown, a kind of textile dye filtration reuse processing method mainly comprises the following steps:

[0033] Step 1: Equipment inspection: before enabling the textile dye filtration equipment to filter textile dyes, check the operation of the equipment;

[0034] Step 2: Manual feeding: Manually push the connecting rod 26 so that the connecting rod 26 passes through the filter plate 24 and docks with the docking block 27, and then manually pours the textile dye liquid into the water tank 22 to achieve manual feeding the goal of;

[0035] Step 3: Dye filtration: After completing the manual feeding operation in step 2, the No. 1 motor works, and drives the connecting rod 26 to rotate through the docking block 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com