Pulp embrittling device and pulp embrittling process thereof

A technology of embrittlement and pulp, applied in the directions of transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of not being able to satisfy consumers, no solution proposed, long processing time, etc., and achieve high practical value And the effect of promoting value, thorough embrittlement process, and improving embrittlement quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

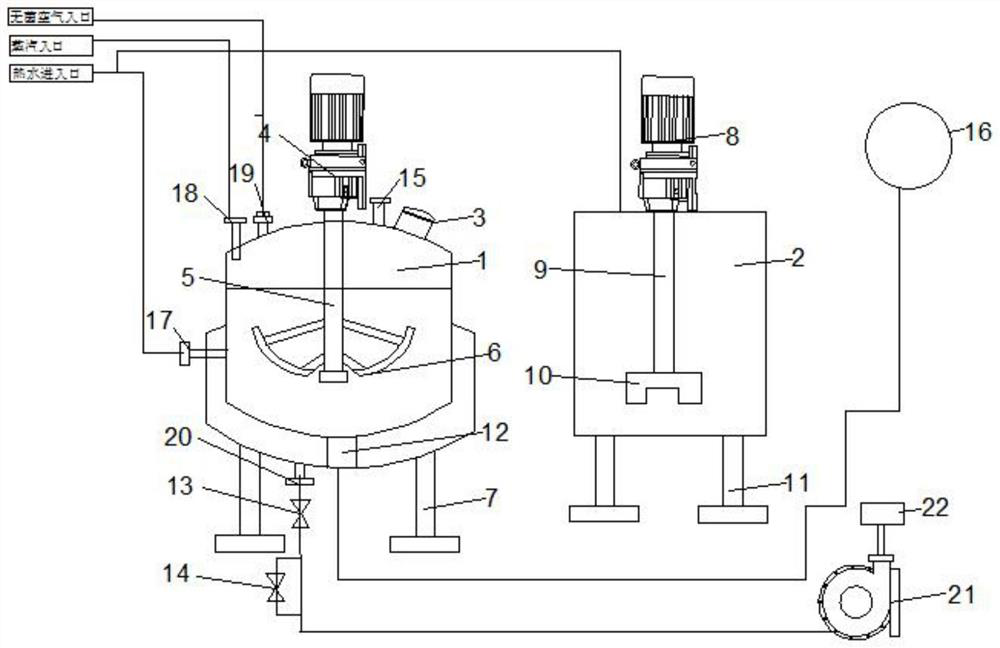

[0050] A pulp embrittlement process, the pulp embrittlement process comprising:

[0051] A. Add the cleaned pulp raw material and water into the embrittlement tank 1, the bottom of the embrittlement tank 1 is connected with a CIP recovery pump 21, and the CIP recovery pump 21 is connected with a CIP return terminal 22;

[0052] B. The embrittlement tank 1 is connected with sterile air through the sterile air inlet 19, and then an alkaline deodorant is added to the inside of the embrittlement tank 1, and the rotating shaft-5 is driven by the drive motor-4 to rotate, so that The stirring blade-6 on the rotating shaft-5 stirs the inside of the embrittlement tank 1 evenly, and the stirring time is 60-90min; the alkaline deodorant is sodium hydroxide and sodium carbonate, and the alkaline deodorant The ratio of pulp raw materials is 0.6-1.2wt‰;

[0053] C. The embrittlement tank 1 is connected to hot water through the hot water inlet 18, so that hot water enters the inner upper en...

Embodiment 2

[0059] A pulp embrittlement process, the pulp embrittlement process comprising:

[0060] A. Add the cleaned pulp raw material and water into the embrittlement tank 1, the bottom of the embrittlement tank 1 is connected with a CIP recovery pump 21, and the CIP recovery pump 21 is connected with a CIP return terminal 22;

[0061] B. The embrittlement tank 1 is connected with sterile air through the sterile air inlet 19, and then an alkaline deodorant is added to the inside of the embrittlement tank 1, and the rotating shaft-5 is driven by the drive motor-4 to rotate, so that The stirring blade-6 on the rotating shaft-5 stirs the inside of the embrittlement tank 1 evenly, and the stirring time is 60-90min; the alkaline deodorant is sodium hydroxide and sodium bicarbonate, and the alkaline deodorant The ratio of 0.6-1.2wt‰ of the pulp raw material is added;

[0062] C. The embrittlement tank 1 is connected to hot water through the hot water inlet 18, so that hot water enters the ...

Embodiment 3

[0068] A pulp embrittlement process, the pulp embrittlement process comprising:

[0069] A. Add the cleaned pulp raw materials and water into the embrittlement tank 1, the bottom of the embrittlement tank 1 is connected with a CIP recovery pump 21, and the CIP recovery pump 21 is connected with a CIP return terminal 22;

[0070] B. The embrittlement tank 1 is connected with sterile air through the sterile air inlet 19, and then an alkaline deodorant is added to the inside of the embrittlement tank 1, and the rotating shaft-5 is driven by the drive motor-4 to rotate, so that The stirring blade-6 on the rotating shaft-5 stirs the inside of the embrittlement tank 1 evenly, and the stirring time is 60-90min; the alkaline deodorant is sodium bicarbonate and sodium carbonate, and the alkaline deodorant The ratio of pulp raw materials is 0.6-1.2wt‰;

[0071] C. The embrittlement tank 1 is connected to hot water through the hot water inlet 18, so that hot water enters the inner upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com