Three-dimensional force flexible tactile sensor and preparation method and decoupling method thereof

A tactile sensor, three-dimensional force technology, applied in the field of flexible sensors, can solve the problems of complex sensor decoupling method, inability to achieve decoupling, poor sensitivity, etc., and achieve the effect of increasing effective dielectric constant, improving sensitivity, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

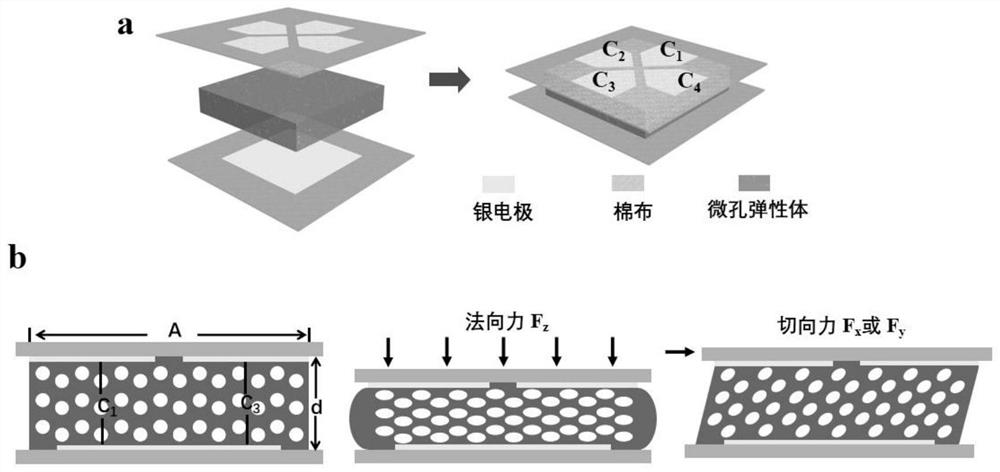

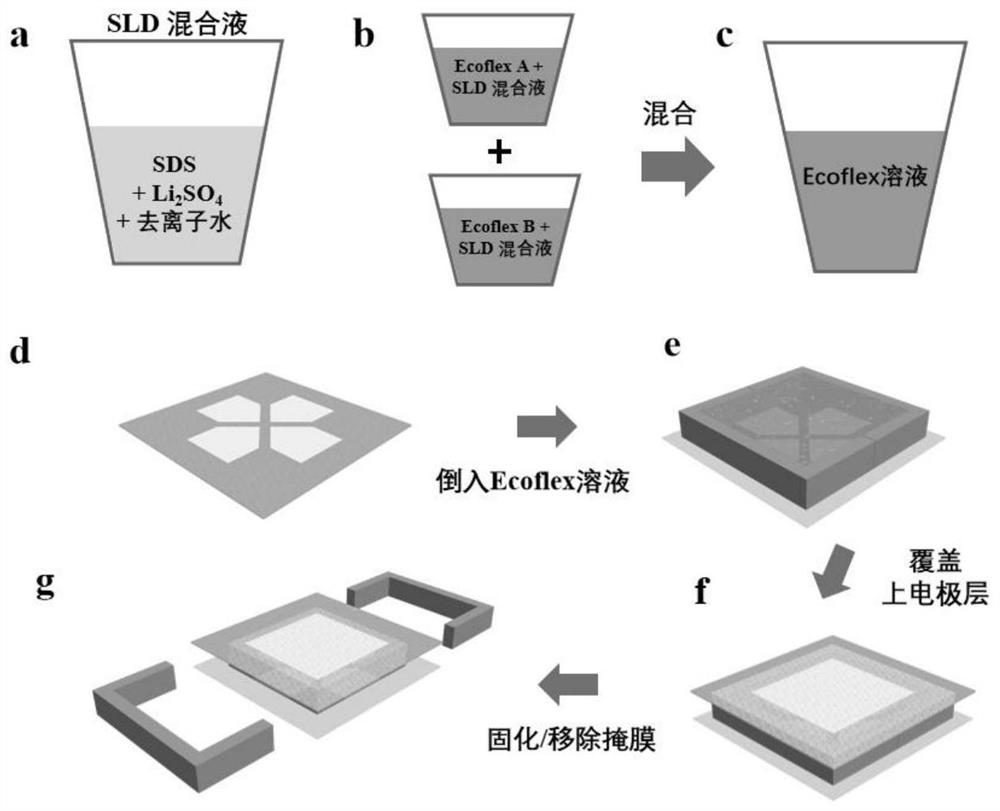

[0053] The invention also discloses a preparation method of a three-dimensional force flexible tactile sensor, comprising the following steps:

[0054] Step 1: Prepare multiple first electrodes on the first elastic layer to obtain the first electrode / elastic composite layer; prepare second electrodes on the second elastic layer to obtain the second electrode / elastic composite layer.

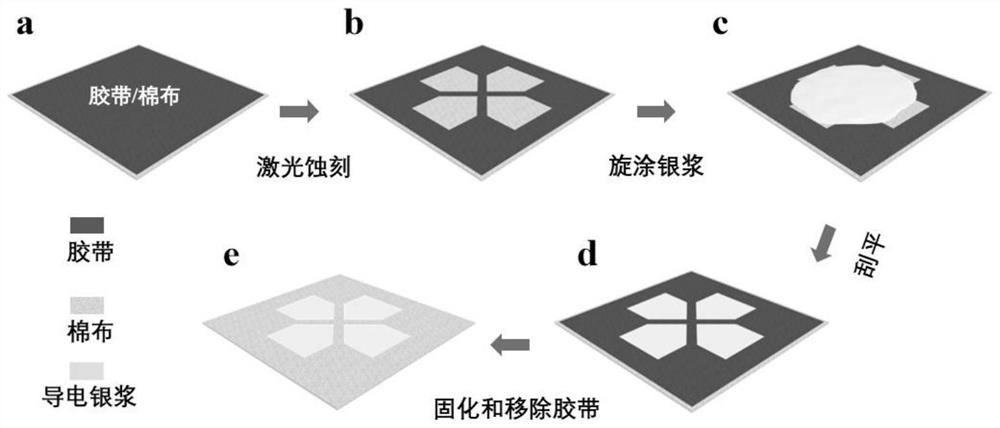

[0055] Wherein, prepare a plurality of first electrodes on the first elastic layer, obtain first electrode / elastic composite layer, comprise the following steps:

[0056] S11. Attach an adhesive layer on one side of the first elastic layer, and etch the adhesive layer to obtain a receiving groove;

[0057] S12. Fill the containing tank with conductive paste, and heat to solidify the conductive paste, wherein the conductive paste is conductive silver paste or conductive polymer;

[0058] S13 , removing the adhesive layer to obtain the first electrode / elastic composite layer.

[0059] Specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com