Execution system for driving automobile gearbox to shift gears

A technology for automotive gearboxes and executive systems, applied in the field of executive systems, can solve the problems of expensive software and hardware, complex and bloated structures, and complicated driving methods, and achieve the effects of low cost, compact layout, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

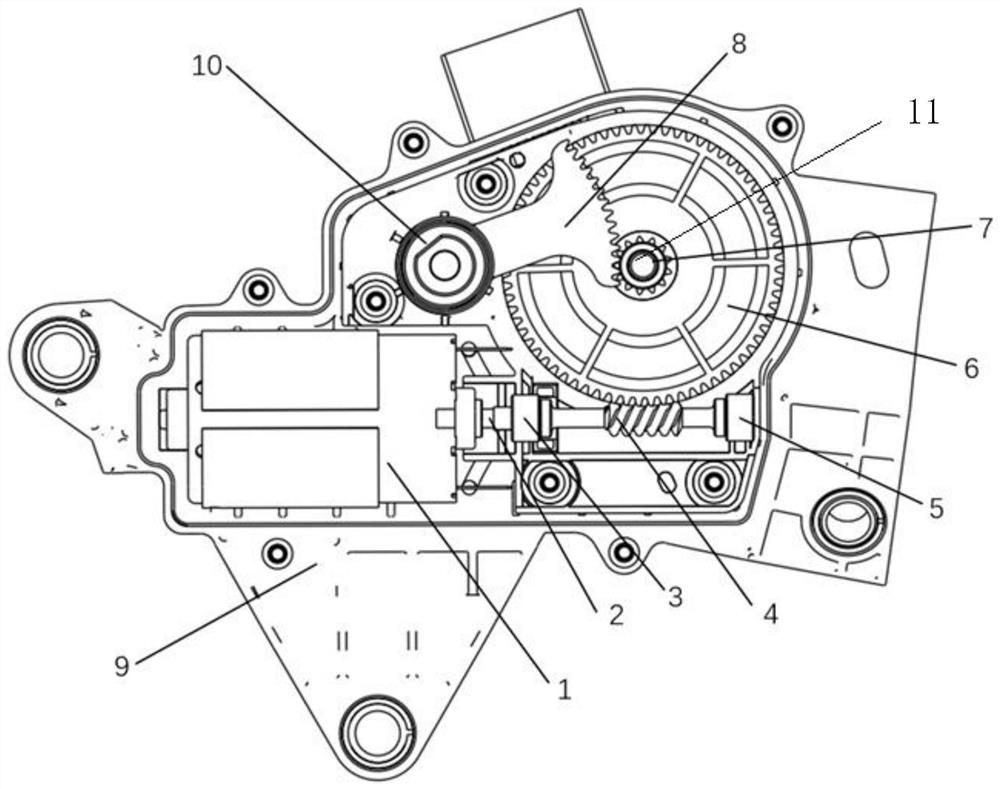

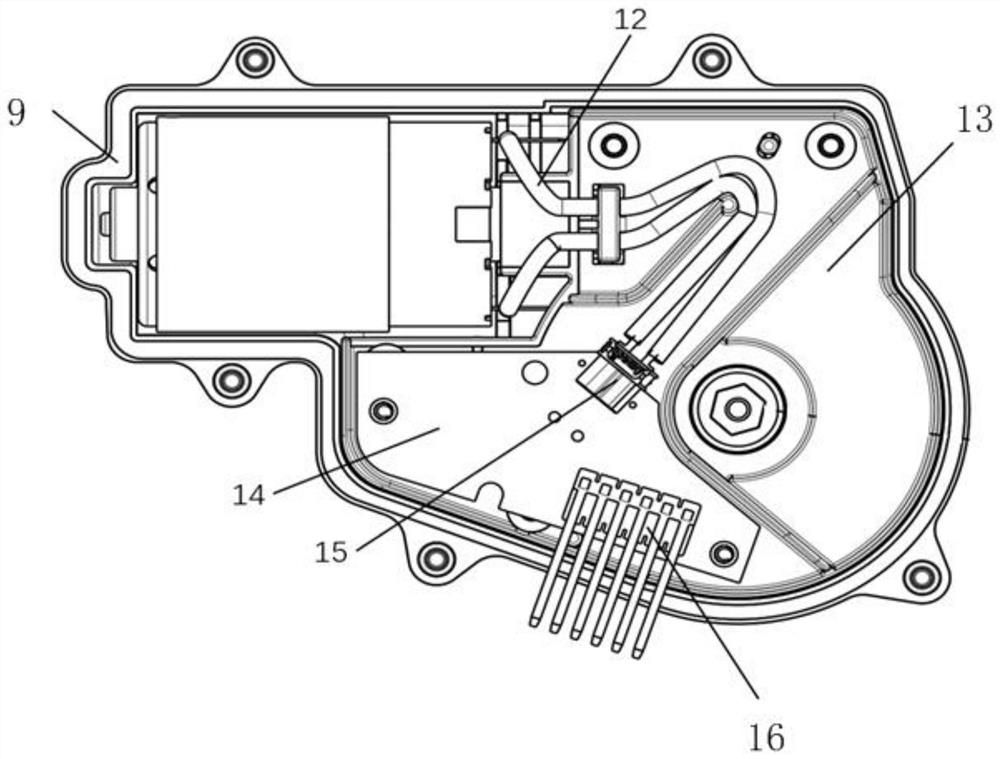

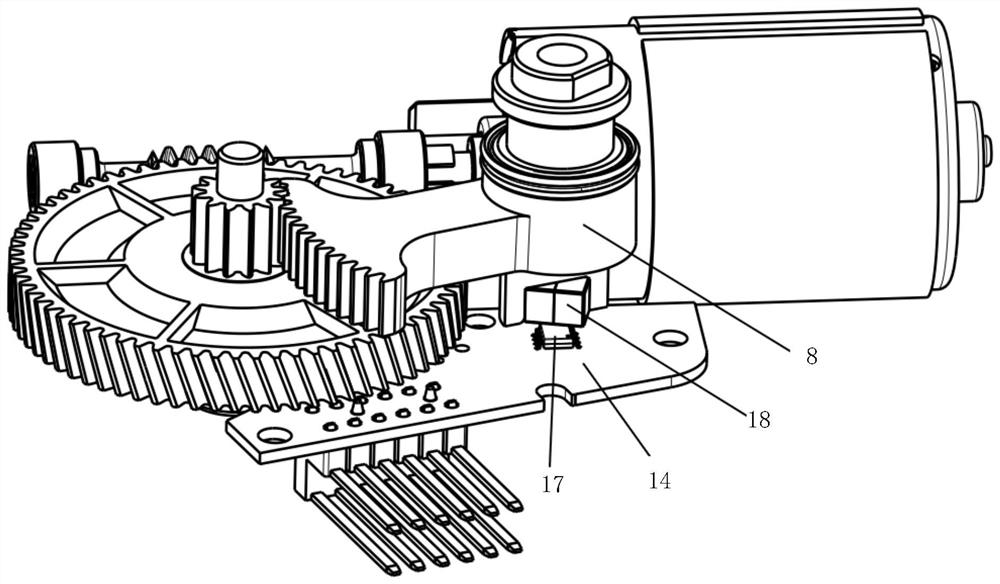

[0026] Such as Figure 1 to 3 As shown, an execution system for driving the automotive gearbox shift, includes a housing 9, a DC motor 1 is provided on one side of the casing 9, the DC motor 1 by output shaft 2 and a worm The 4 phase drive is connected, the worm 4 is located on the other side of the housing 9, and the housing 9 is provided with a turbine 6 by the rotating shaft 11, the turbine 6 is located above the worm 4, and the worm 4 is engaged with the turbine 6. A gear 7 is provided on the rotating shaft 11, and the gear 7 is also fitted at the center of the turbine 6, and the gear 7 is rotatably provided with the turbine 6, and the housing 9 is provided with a rotary output shaft 10, The sector gear 8 in which a synchronous rotation is provided on the rotation output shaft 10, and the sector gear 8 is provided with the gear 7, and the housing 9 is provided with a control circuit board 14, and the front side of the control circuit board 14 is set. With a sensor 17, a magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com