Automatic bricklaying trolley for building construction

A building construction and automatic technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of workers sticking to cement bricks, inconvenience, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

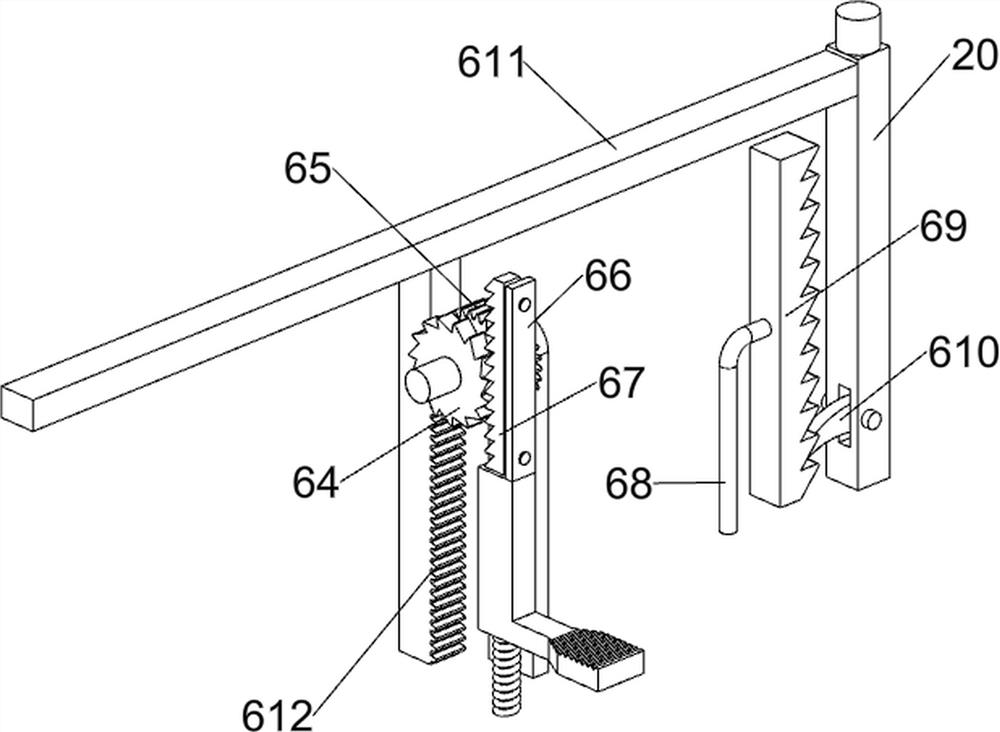

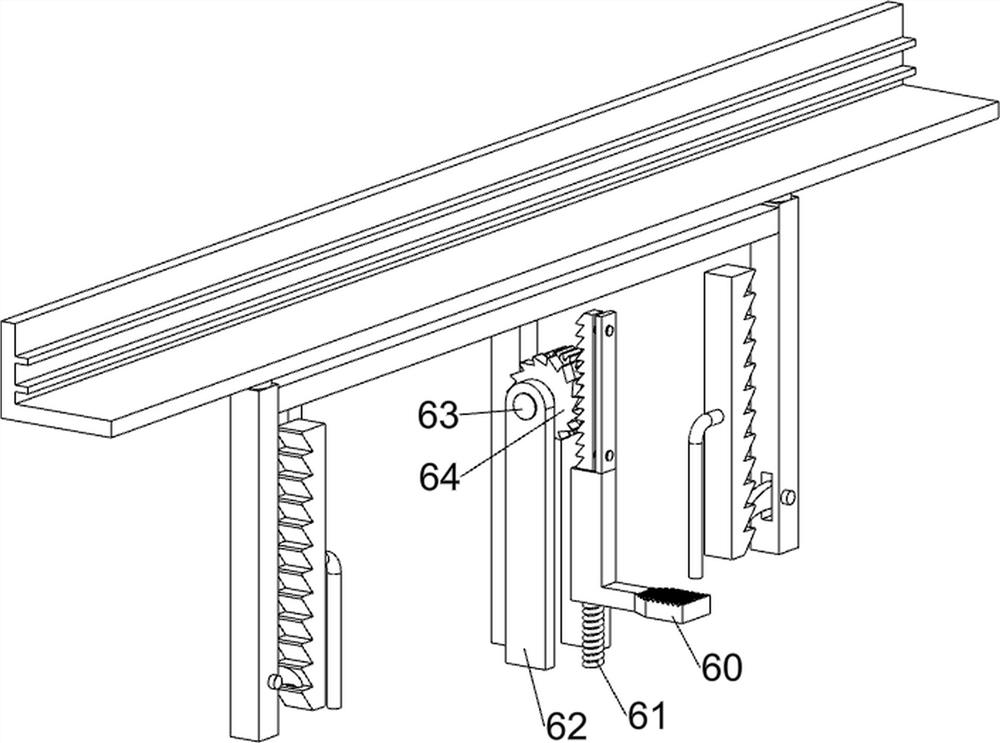

[0032] An automatic bricklaying trolley for building construction, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a moving mechanism 2 and a brick transporting mechanism 3, a moving mechanism 2 is arranged between the base 1, and a brick transporting mechanism 3 is provided on the moving mechanism 2.

[0033] When people need to use this device, first people place this device on the wall that needs bricklaying, and then people can place the cement-coated brick board on the brick transport mechanism 3, and then start the movement mechanism 2 to operate, because The moving mechanism 2 operates intermittently, and the moving mechanism 2 will drive the brick transport mechanism 3 to operate intermittently, so that the brick transport mechanism 3 drives the brick boards to move to the left intermittently, so that when the cement-coated brick boards fall from the left side of the mobile mechanism 2 to the wall After getting on, the moving mechanism 2 can m...

Embodiment 2

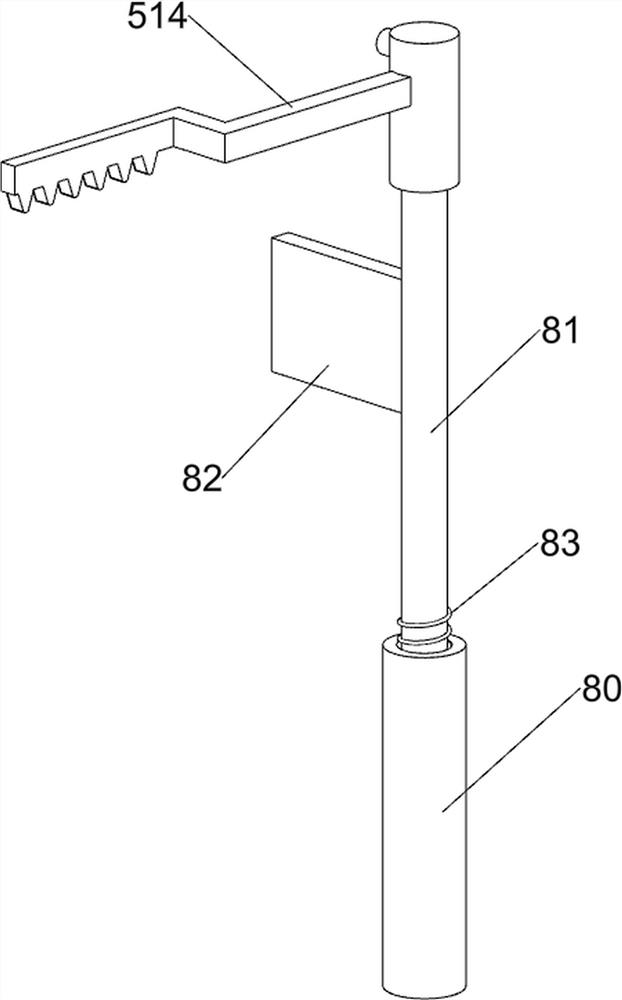

[0038] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, it also includes a spreading mechanism 4, and the spreading mechanism 4 includes a support rod 40, a material box 41, a third bearing seat 42, a fifth rotating shaft 43, a first gear 44, a second support column 45, and a second slide rail 46. Blocking plate 47, guide rod 48, first spring 49, top block 410, first fixed block 411, slide bar 412, second spring 413, wedge block 414, first support block 415, arc-shaped slide rail 416 , slider 417, the third spring 418 and the second bevel gear 419, the left side of the top of the mounting plate 21 is symmetrically provided with support rods 40, the support rods 40 are provided with a material box 41, and the left side of the mounting plate 21 is symmetrically provided with the third Bearing block 42, the fifth rotating shaft 43 is arranged between the third bearing seat 42, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com