Reinforced concrete frame column steel reinforcement cage and manufacturing method thereof

A technology of reinforced concrete and production method, applied in the direction of columns, piers, pillars, etc., can solve the problems of a large number of unconventional steel cages, lack of mature experience of workers, time-consuming and laborious production, etc., so as to save the amount of steel bars and ensure the quality of the project , the effect of excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

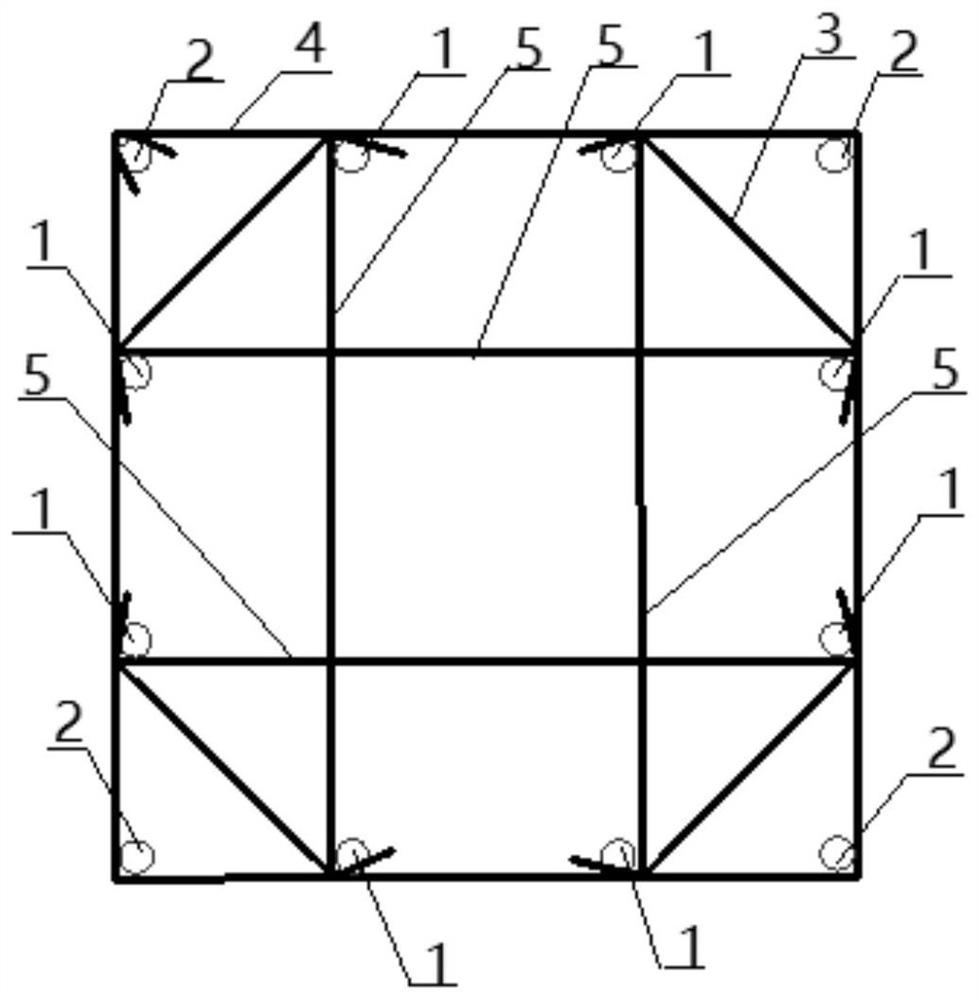

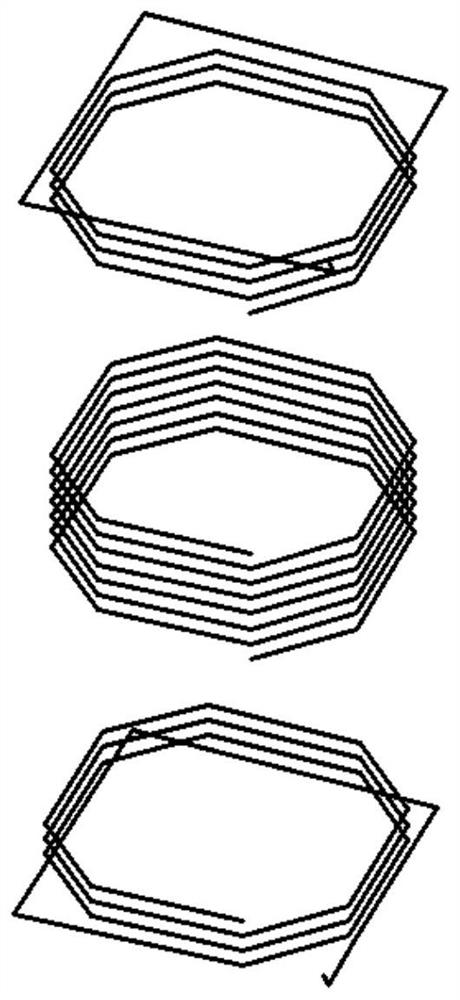

[0028] This embodiment provides a reinforced concrete frame column reinforcement cage, including a grouting sleeve reinforcement cage and a column reinforcement cage, the grouting sleeve reinforcement cage is arranged at the lower part of the column reinforcement cage, and the column reinforcement cage includes an inner longitudinal main reinforcement 1, an outer longitudinal reinforcement cage Main reinforcement 2, octagonal spiral stirrup 3, rectangular stirrup 4 and tie reinforcement 5, one end of the inner longitudinal main reinforcement 1 is fixedly installed on the top of the grouting sleeve reinforcement cage, and the inner longitudinal main reinforcement 1 is set to 8 and is octagonal Arranged, one end of the outer longitudinal main reinforcement 2 is fixedly installed on the top of the grouting sleeve reinforcement cage. The outer layer longitudinal main ribs 2 are set to 4 and distributed in a rectangular shape, the height of the inner layer longitudinal main ribs 1 a...

Embodiment 2

[0030] In this embodiment, the present invention is further explained and illustrated by taking the steel cage required for making a reinforced concrete frame column with a height of 6.3 meters and a width of 2.4 meters as an example. The manufacturing method of this embodiment includes the following steps:

[0031] Step 1. Make 3 units of octagonal spiral stirrups: Cut the original steel bars according to the longitudinal main bars of the required length of the column reinforcement cage on the design drawing, and then put a cut ribbed rebar with equal cross-section on the spiral stirrup forming machine Bending continuously to form an octagonal spiral stirrup;

[0032] Step 2. Piercing the longitudinal main reinforcement of the outer layer 2: Piercing the rectangular stirrup 4 main reinforcement at the four corner holes of the reinforcement cage of the grouting sleeve.

[0033] Step 3. Piercing the longitudinal main reinforcement of the inner layer 1: Piercing the main reinfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com