Aloe peeling device for aloe gel production

A kind of technology of aloe vera gel and aloe vera, applied in metal processing and other directions, can solve the problems of low production efficiency, aloe vera peeling relying on manual labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

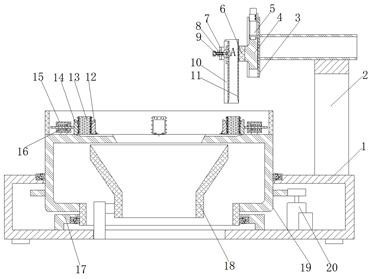

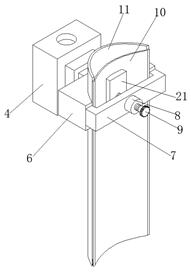

[0029] refer to Figure 1-5 , an aloe vera peeling device for aloe gel production, comprising a workbench 1 with a cavity in a cuboid structure, the middle part of the upper surface of the workbench 1 is rotatably connected with a rotating pallet 19 with a cavity in a cylindrical structure, and Four sets of clamping devices are fixed on the upper surface of the rotating pallet 19 near the edge of the circumference, a support frame 2 is fixed on the upper surface of the workbench 1 near the edge, and a beam tube is fixed on the top of the support frame 2, and the beam tube is far away from the support frame. One end of the 2 is fixed with a C-shaped steel column 3, and a T-shaped slider 4 is slidably connected in the chute of the C-shaped steel column 3, and the side of the T-shaped slider 4 away from the bottom of the groove is fixed with an arc-shaped clamping block 6, and the arc-shaped clamp An arc-shaped blade 11 is welded in the arc-shaped groove of the block 6, and a spr...

Embodiment 2

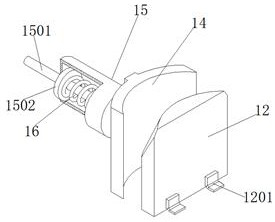

[0039] refer to figure 1 and image 3 , an aloe vera peeling device for aloe gel production. Compared with Embodiment 1, this embodiment also includes that each clamping device includes a block 12 hinged below the spring knife plate 10, fixed on the upper surface of the workbench 1 The positioning barrel 15 and the mobile clamping block 14 arranged at the end of the positioning barrel, the hinge hinge shaft at the bottom of the block 12 are provided with torsion springs, which can ensure that the block 12 always produces an extruding force to the aloe.

[0040] Wherein, the center of positioning barrel 15 is slidably connected with guide rod 1501, and the circumferential outer wall of guide rod 1501 is fixed with annular retaining ring close to the inside of positioning barrel 15, and the side of annular retaining ring away from moving clamping block 14 is fixed with return spring 16 , the moving clamping block 14 is arranged in an arc-shaped plate structure, and the side opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com