Batten bending device

A technology of bending device and slat, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of slat waste, error, easy deformation of slat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A slat bending device such as figure 1 As shown, it includes a bottom plate 1, a placing table 2, an inner bending mechanism 3 and an outer bending mechanism 4. An outer bending mechanism 4 is provided, and the inner bending mechanism 3 is located in the inner middle of the outer bending mechanism 4 .

[0028] When people need to bend the slats, people first place the untreated slats on the placement table 2, and then manually push the parts, the operation of the device parts drives the operation of the parts to clamp and fix the slats, and the outer bending The 4 parts of the mechanism perform external bending on the slats. After the operation of the 4 components of the external bending mechanism is completed, the 4 components of the external bending mechanism are reset. After the bending is completed, the bending work of the slats is completed, and people take off the folded slats. After the required slats are bent and processed, people manually close the device so t...

Embodiment 2

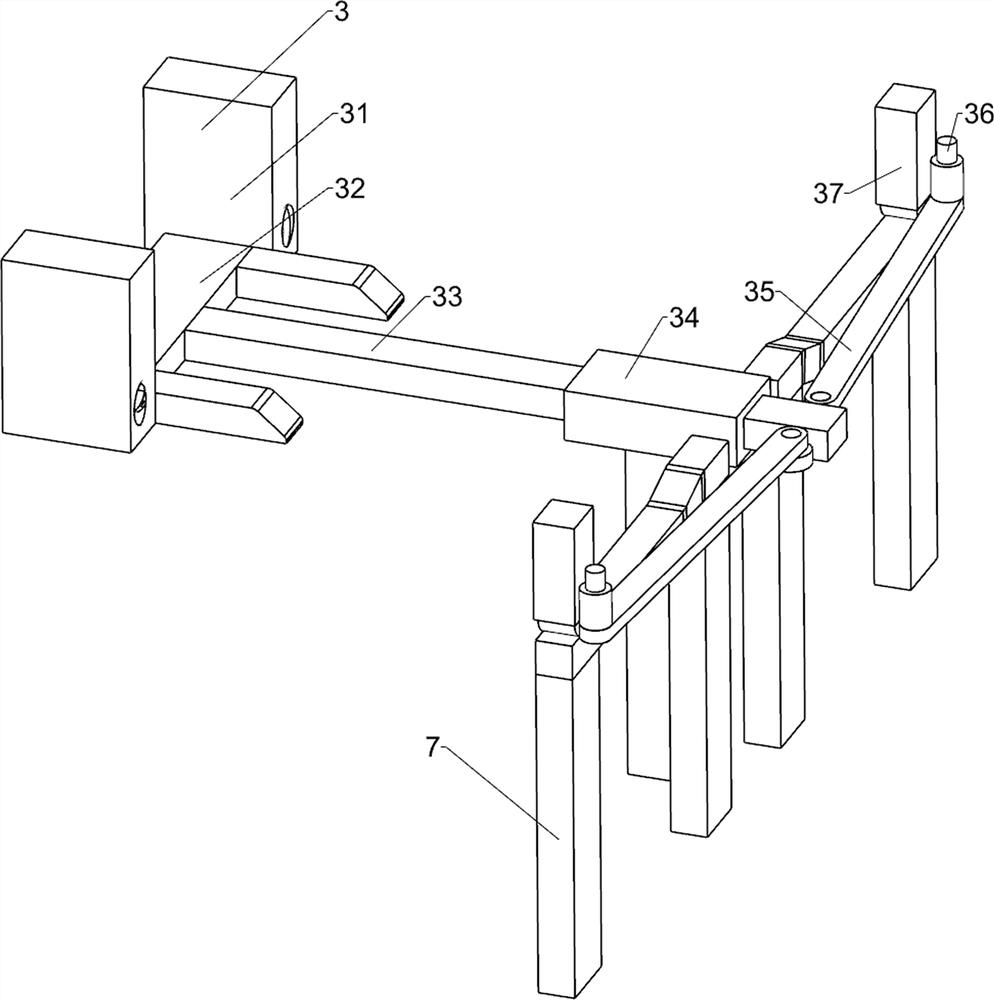

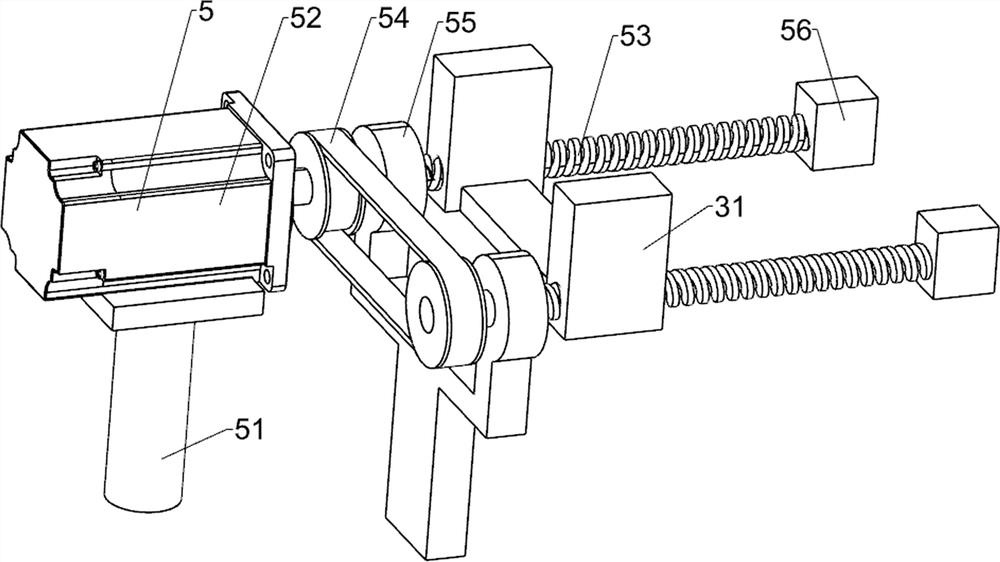

[0030] On the basis of Example 1, such as figure 2 As shown, the inner bending mechanism 3 includes a large pressing block 31, a connecting plate 32, a push rod 33, a rod seat 34, a movable rod 35, a connecting column 36 and a middle pressing block 37, and the middle part of the left side of the platform 2 is opened horizontally and symmetrically. There are rectangular slots, the number of rectangular slots is 2, and a large pressing block 31 is slidingly arranged in the two rectangular slots, a connecting plate 32 is arranged between the large pressing blocks 31, a push rod 33 is arranged in the middle of the right side of the connecting plate 32, and the bottom plate 1 The middle part is provided with a rod seat 34, and the right end of the push rod 33 is slidably connected with the rod seat 34, and both sides of the right end of the push rod 33 are rotatably provided with a movable rod 35, and the movable rod 35 is positioned at the right side of the rod seat 34, and the mo...

Embodiment 3

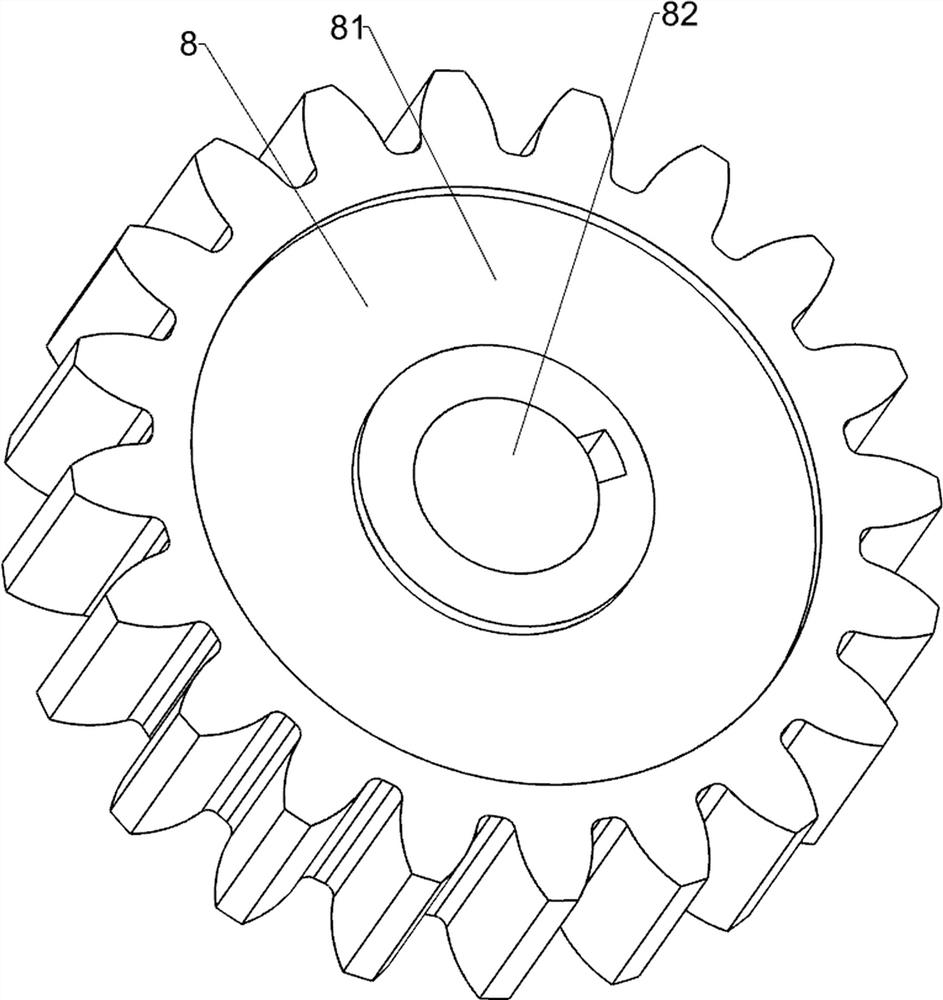

[0033] On the basis of Example 2, such as image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7As shown, the outer bending mechanism 4 includes a synchronous rod 41, a connecting rod 42, a connecting seat 43, a slide plate 44, a chute 45, and a small pressing block 46. Groove 45 is positioned at two vertical slide rail both sides, all slides are provided with slide plate 44 in the chute 45, and the left side of slide plate 44 is all provided with small pressing block 46, and small pressing block 46 is positioned at positioning device 8 parts inner side, and slide plate 44 top right Both sides are provided with connecting seat 43, and the tops of two connecting seats 43 are all rotatably provided with connecting rod 42, and the rotating type between two connecting rods 42 is provided with synchronous rod 41.

[0034] When people need to bend the slats outward, the slats are tightened and fixed, the operation of the 3 parts of the inner bending mechanism drives the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com