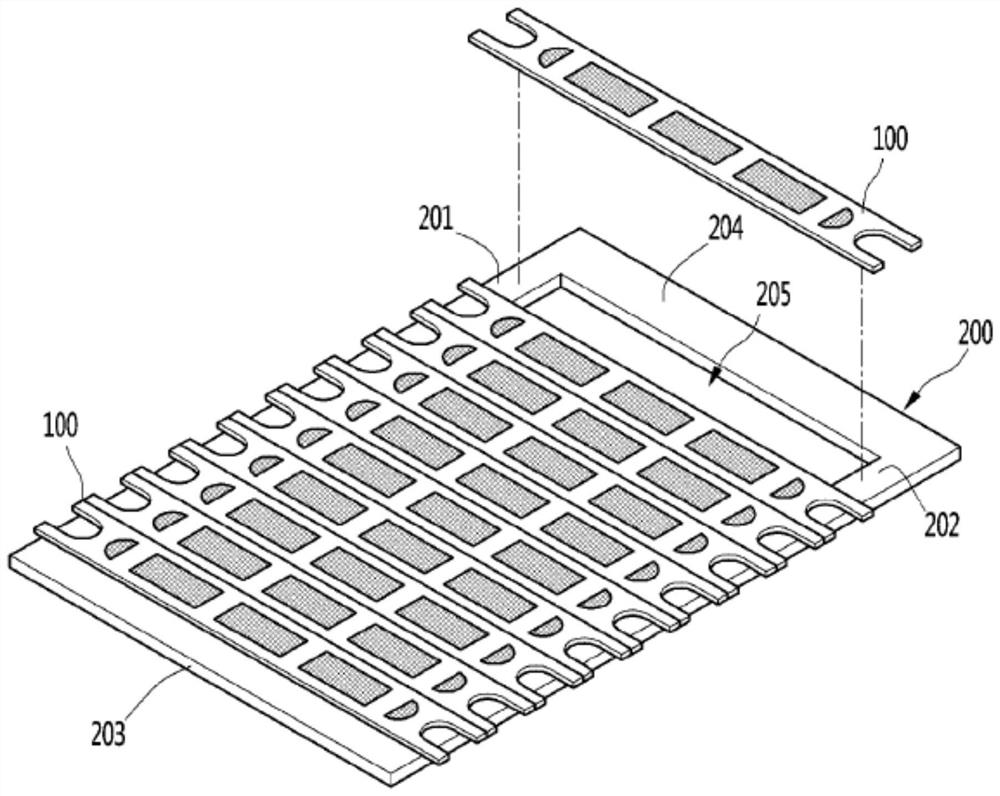

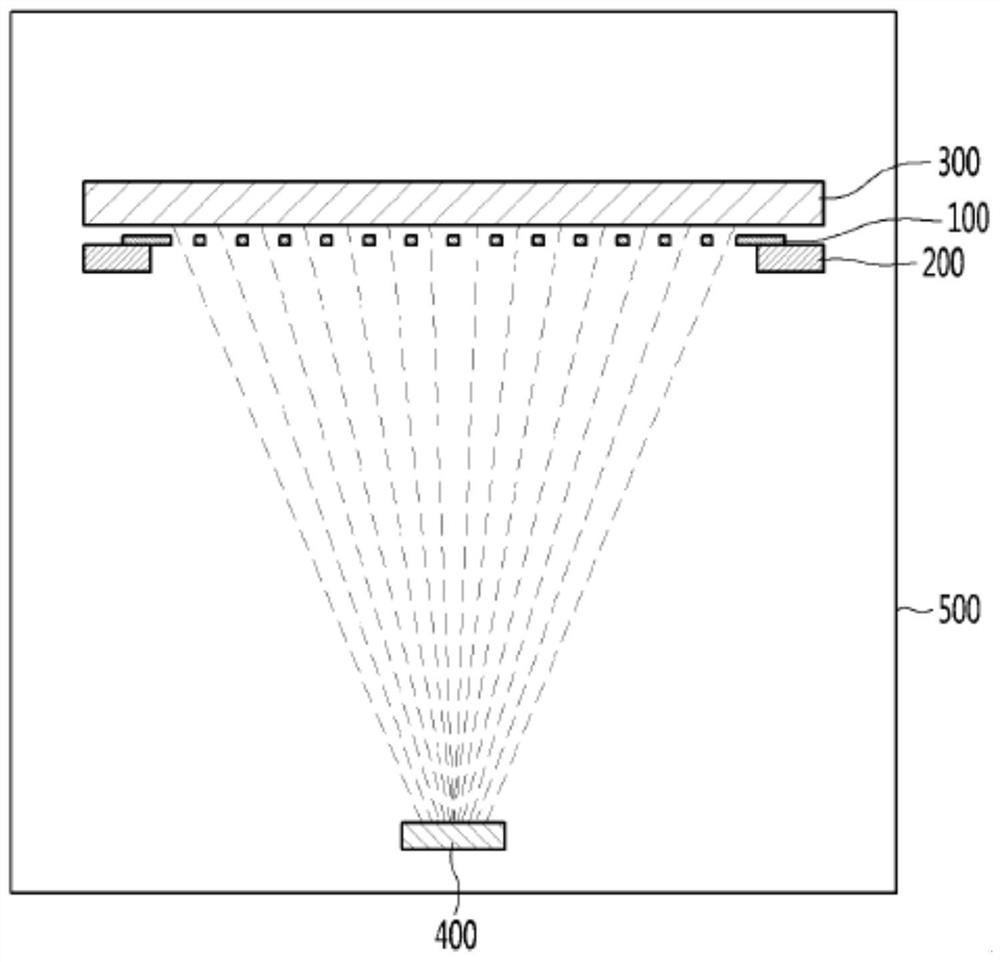

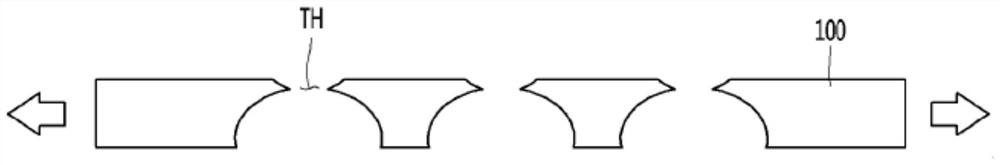

Metal plate deposition mask for OLED pixel deposition

A metal material, evaporation technology, applied in metal material coating process, vacuum evaporation plating, sputtering plating, etc. Remove and other problems, to achieve the effect of enhancing corrosion resistance, increasing the number of usable times, and preventing evaporation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the technical idea of the present invention is not limited to some of the described embodiments, but can be realized in various other forms, and within the scope of the technical idea of the present invention, one or more components of the multiple embodiments can be modified. Selectively combine and replace to use. In addition, as long as the terms (including technical and scientific terms) used in the embodiments of the present invention are not specifically defined, they can be interpreted as meanings commonly understood by those skilled in the art, and are the same as previously defined terms. , commonly used terms can be interpreted based on considering the meaning of the relevant technology in the context. In addition, the terms used in the embodiments of the present invention are for describing various embodiments, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com