Thermal manikin manufacturing method based on flexible stretchable heating film and thermal manikin

A technology of thermal manikin and manufacturing method, which is applied in the field of thermal manikin, and can solve problems such as uneven temperature distribution, poor temperature uniformity of thermal manikin, inability to apply thermal manikin surface, etc., and achieve uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

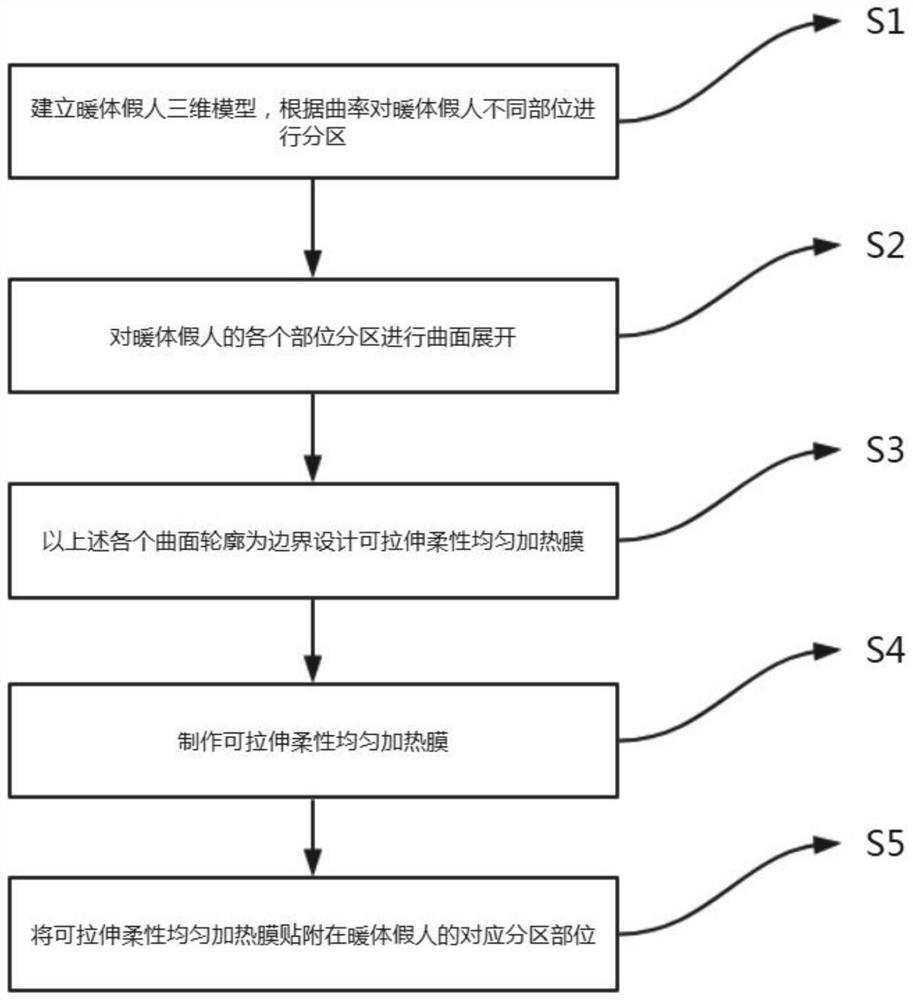

[0026] like figure 1 As shown, a method for manufacturing a thermal manikin based on a flexible and stretchable heating film, specifically includes the following steps:

[0027] Step S1, establishing a three-dimensional model of the thermal manikin, and partitioning different parts of the thermal manikin according to the curvature.

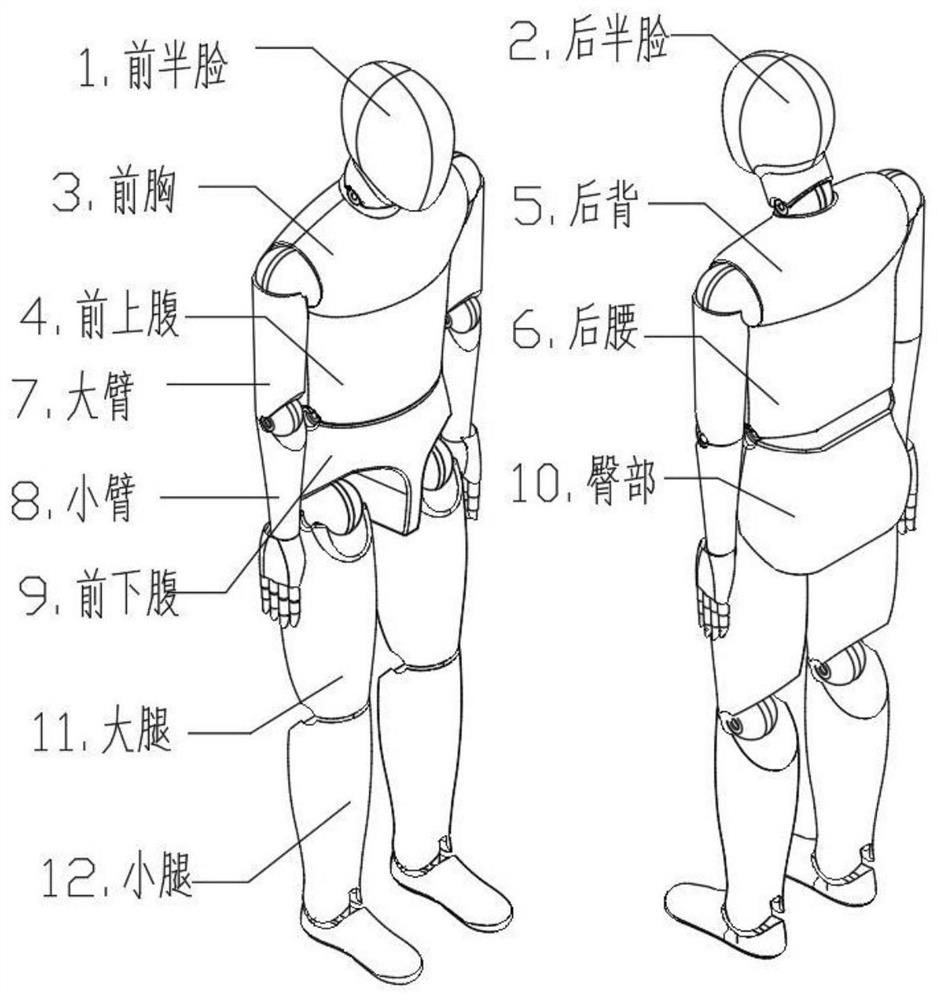

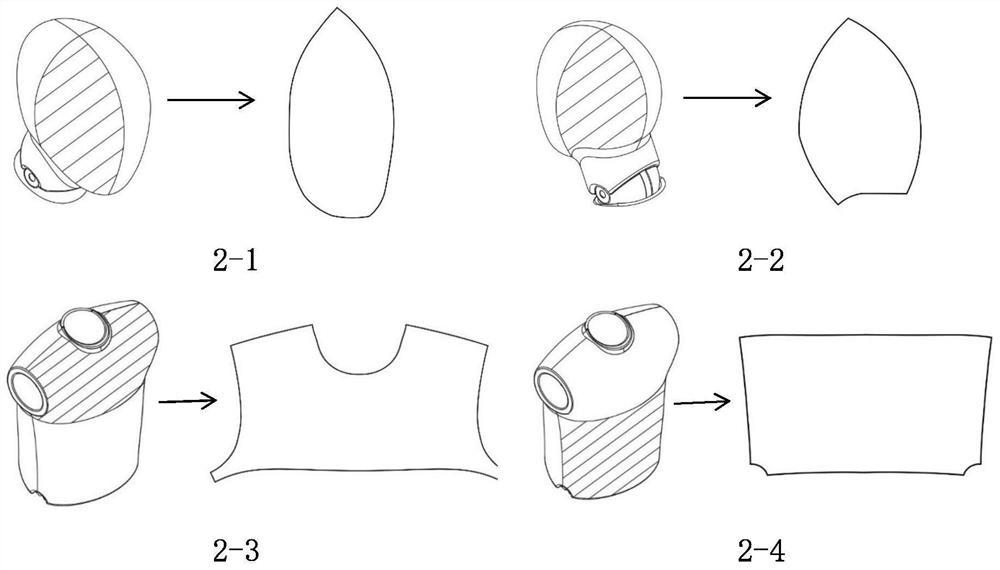

[0028] like figure 2 Shown: Use 3D software to build a 3D model of the thermal manikin, and divide the different parts of the thermal manikin according to the curvature. The thermal manikin has a left-right symmetrical structure. The back half of the face, front chest, front upper abdomen, back, back waist, upper arm, forearm, front lower abdomen, buttocks, thighs, and calves are divided into 12 parts. According to the application environment of the thermal manikin, it can also be divided into 12 parts. On the basis of the part divisions, further increase the part divisions of the thermal manikin, for example, increase the part divisions of the...

Embodiment 2

[0050] A thermal manikin made by the manufacturing method described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com