Lighter fire test detection equipment for factory

A technology for testing equipment and lighters, applied in lighting and heating equipment, combustion ignition, combustion methods, etc., can solve problems such as inapplicability to factory testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

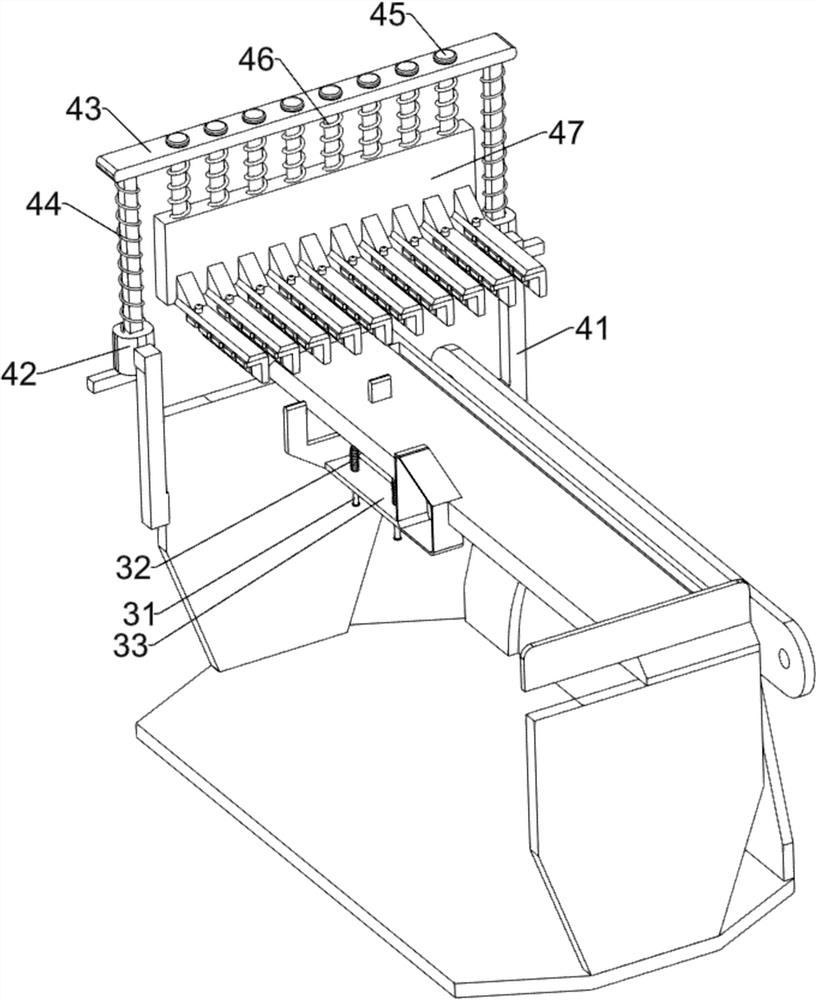

[0060] A factory uses a lighter fire test detection equipment, such as figure 1 As shown, it includes a frame 1, a workbench 2, a positioning mechanism 3 and a manual pressing mechanism 4. The frame 1 is connected with a workbench 2, the workbench 2 is provided with a positioning mechanism 3, and the frame 1 is provided with a manual press. Press down mechanism 4.

[0061] When people need to use the present invention, they first place a plate lighter that needs to be tested on the positioning mechanism 3, and then people press the manual pressing mechanism 4 to move downward, and the manual pressing mechanism 4 touches the lighter, and the manual pressing mechanism 4 Press the switch of the lighter to turn on the fire test, keep pressing the manual pressing mechanism 4 for a few seconds, the fire test is completed, then release the manual pressing mechanism 4, and then remove the lighter, if you need to give a new one Lighter test fire, repeat the above operations, people ca...

Embodiment 2

[0063] On the basis of Example 1, such as figure 1 and figure 2 As shown, the positioning mechanism 3 includes a first connecting rod 31, a first spring 32 and a limit plate 33. Two first connecting rods 31 are arranged on the top of the inner side of the workbench 2, and two first connecting rods 31 are provided with two first connecting rods. Slidingly connected to the limit plate 33, the limit plate 33 is slidably connected to the workbench 2, the two first connecting rods 31 are wound with a first spring 32, and the first spring 32 is connected to the workbench 2 and the limit plate 33 .

[0064] Put a plate lighter that needs to be tested on the limit plate 33, under pressure, the limit plate 33 moves downward, the first spring 32 becomes stretched, and then people press the manual pressing mechanism 4 to move downward , the manual depressing mechanism 4 touches the lighter, the manual depressing mechanism 4 presses the switch of the lighter to open the fire test, keep...

Embodiment 3

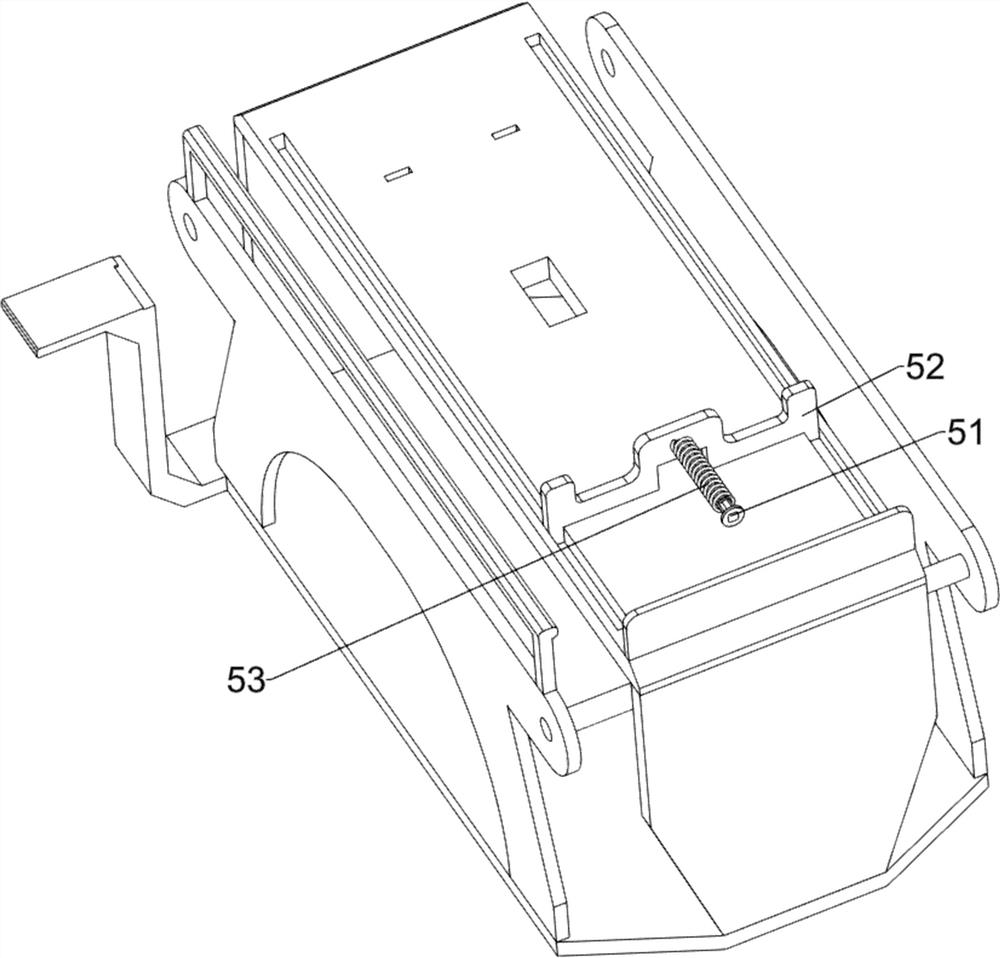

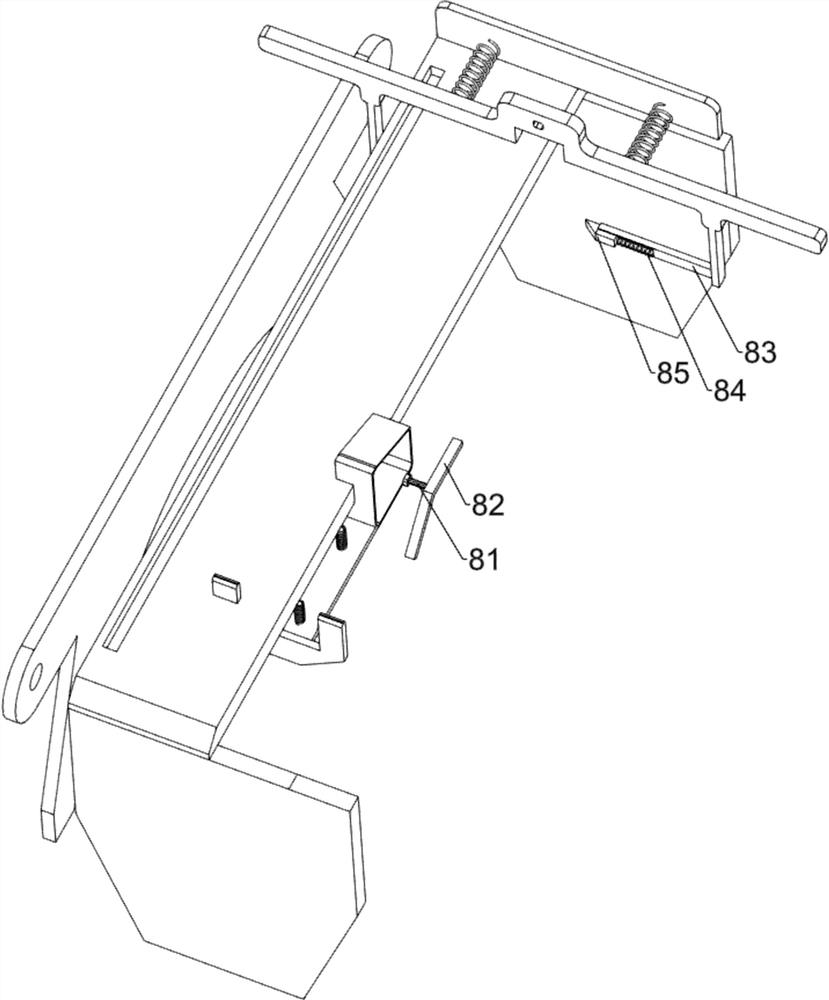

[0068] On the basis of Example 2, such as figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a pusher mechanism 5 is also included, and the workbench 2 is provided with a pusher mechanism 5, and the pusher mechanism 5 includes a pull rod 51, a first push plate 52 and a fourth spring 53, and the workbench 2 is slidably provided with The first push plate 52 is provided with a pull rod 51 on the right side of the first push plate 52 , a fourth spring 53 is wound around the pull rod 51 , and the fourth spring 53 is connected with the first push plate 52 .

[0069] Put a plate lighter that needs to be tested on the workbench 2, then push the pull rod 51 to move to the left, the pull rod 51 drives the first push plate 52 to move to the left, the pull rod 51 drives the fourth spring 53 to move to the left, the first push plate 52 drives the lighter to move to the limit plate 33 to the left, press and hold the U-shaped pressure bar 43 to move downwards, and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com