Integrated square hole washing and fishing combined drill

An integrated and compound drilling technology, which is applied in earthwork drilling, percussion drilling, rotary drilling, etc., can solve the problems of increasing working time, increasing labor costs and equipment input costs, etc., to increase working time, increase Labor cost and equipment input cost, and the effect of reducing equipment input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

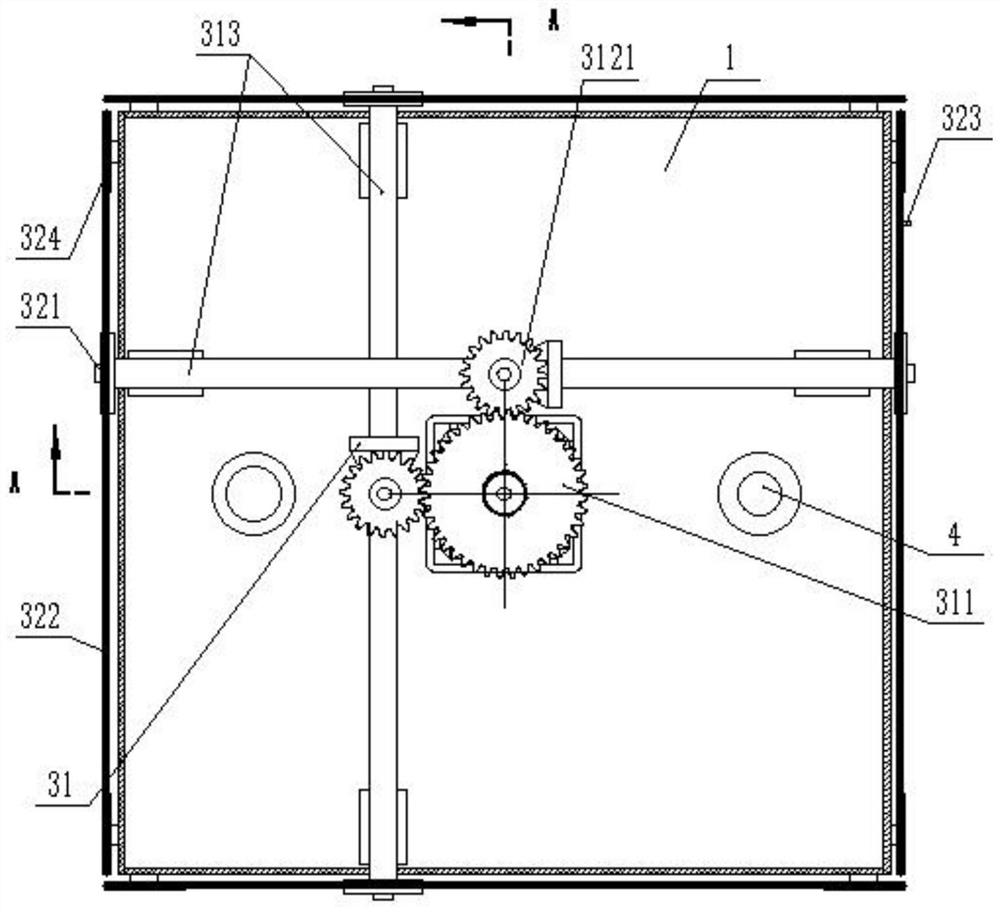

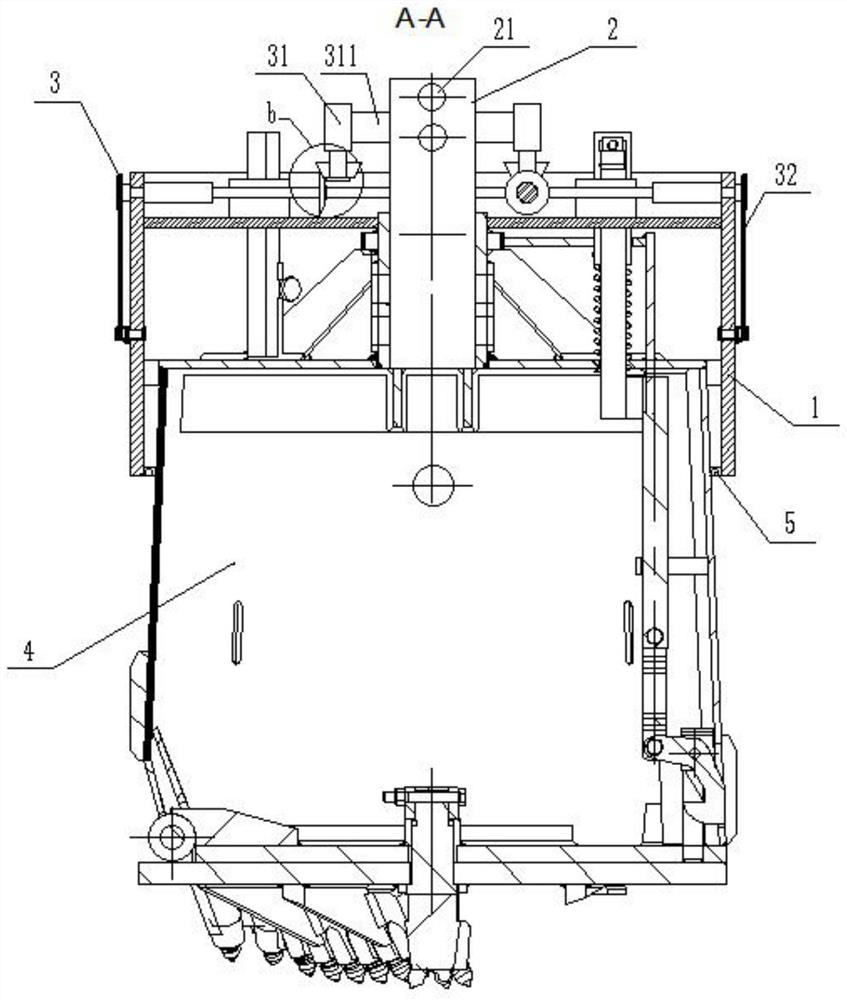

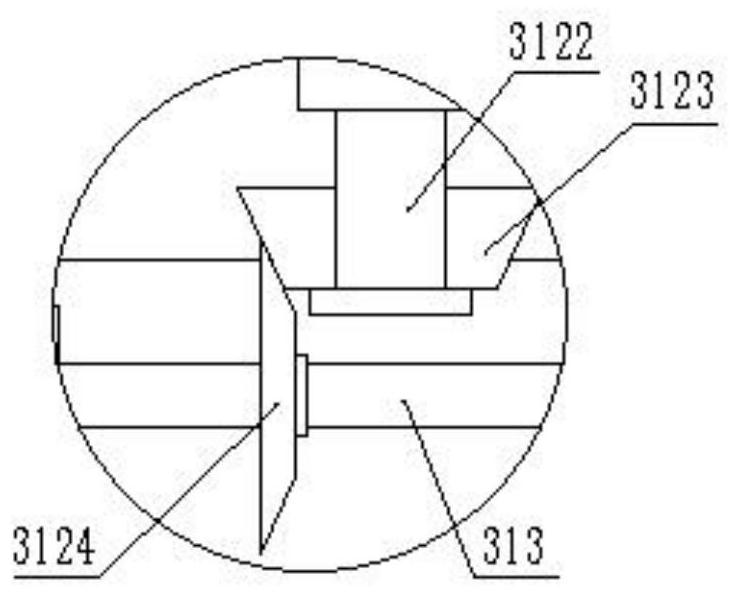

[0022] The invention provides an integrated square hole washing and fishing composite drill, which can realize excavation of the square pile hole and at the same time take out the accumulated soil of the square pile hole, reducing equipment investment cost; including: main shell 1 , a drive shaft 2, a square pile hole drill bit 3 and a rotary drill 4, the drive shaft 2 is rotatably installed in the main housing 1, the drive shaft 2 has a pin hole 21, and the external power machine is driven and connected with the drive shaft 2 through the pin hole 21; The pile hole drill bit 3 is installed on the main housing 1, and is drivenly connected with the transmission shaft 2. The square pile hole drill bit 3 includes a transmission mechanism 31 and a chain cutting mechanism 32; the transmission mechanism 31 is installed on the main casing 1, and is located in the main casing On the top of the body 1, the chain cutting mechanism 32 is installed on the surface around the main casing 1; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com