Snow shovel

A snow shovel and shovel block technology, applied in the field of snow shovels, can solve problems such as large limitations, poor snow removal effect, and impact on traffic safety, and achieve the effects of reducing use limitations, improving snow shoveling effects, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

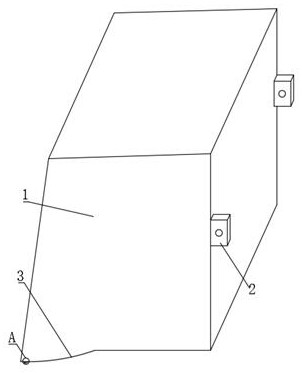

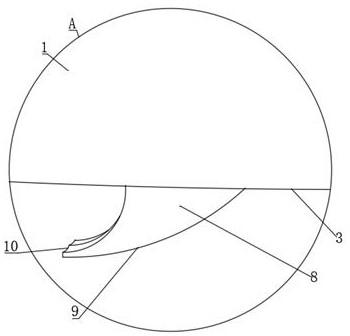

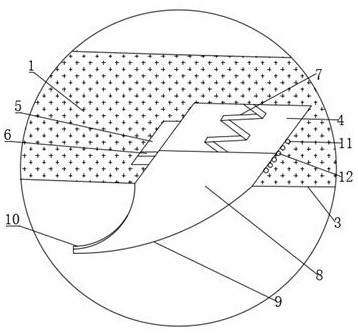

[0027] refer to Figure 1-3 , a snow shovel, comprising a snow shovel body 1, a plurality of mounting blocks 2 fixed to one side of the snow shovel body 1 by bolts, mounting holes are provided on the mounting blocks 2, the front section of the snow shovel body 1 is set as a trapezoid, and the snow shovel body The bottom of the shovel body 1 is provided with a first arc-shaped portion 3, and the bottom of the first arc-shaped portion 3 is provided with a plurality of installation grooves 4 evenly distributed in the longitudinal direction. The first spring 7 is fixed in the installation groove 4 by bolts, and the bottom of the first spring 7 is The shovel block 8 is fixed by bolts, the inner wall of the installation groove 4 is provided with a limit groove 5, and the limit block 6 is slidably connected in the limit groove 5, and the limit block 6 and the shovel block 8 are fixedly connected by bolts, and the shovel block 8 The bottom is provided with a second arc-shaped part 9, ...

Embodiment 2

[0031] refer to Figure 1-5 , a snow shovel, the bottom of the second arc portion 9 is provided with a plurality of embedding grooves 13 distributed in an annular array, the embedding grooves 13 are rotatably connected with a roller 14, and the outer wall of the roller 14 is welded with a plurality of rows distributed in an annular array Snowboard 15, snow expelling plate 15 sections are set to crescent shape.

[0032] In the present invention, the inner arc surface of the snow ejector 15 is provided with a booster portion 16, and the cross section of the booster portion 16 is arranged in a wave shape, which can increase the roughness of the surface of the snow ejector 15, thereby turning the snow farther.

[0033] In the present invention, the cut-off plate 17 is welded to the bottom of the snow discharge plate 15, and the bottom of the cut-off plate 17 is set in a pointed shape, which can cut off the hard snow blocks, so that the snow discharge plate 15 can turn the snow blo...

Embodiment 3

[0036] refer to Figure 1-6 , a kind of snow shovel, one end of the snow shovel body 1 is fixed with a box by bolts, a plurality of guide grooves are provided inside the snow shovel body 1, and the guide grooves are respectively connected with the box body and the installation groove 4, and the top of the shovel block 8 is provided with In the collecting chamber, a material guide pipe 18 is arranged inside the shovel block 8, and a discharge mechanism is arranged at the bottom of the material guide pipe 18.

[0037] In the present invention, a groove 19 is provided on the inner wall of one side of the embedding groove 13 of the discharge mechanism, and a second spring 20 is fixed in the groove 19 by bolts, and a clamping rod 21 is fixed on the other side of the second spring 20 by bolts. It is slidably connected with the groove 19, and a material leakage port 22 is opened through the clamping rod 21. The clamping rod 21 is in natural contact with the snow discharge plate 15, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com