Sludge treatment system

A sludge treatment and sludge technology, applied in the field of sludge treatment system, can solve the problems of unconsidered equal-diameter structure, inability to realize manual takeover, damage to the filter screen, etc., so as to improve the space utilization rate and avoid the effect of manpower being unable to drive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] As shown in the figure: a sludge treatment system, the sludge treatment system includes a sand and gravel separation module, a liquid medicine mixing module, and a sludge dehydration module; the sludge is sequentially processed through the sand and stone separation module, the medicine liquid mixing module, and the sludge dehydration module;

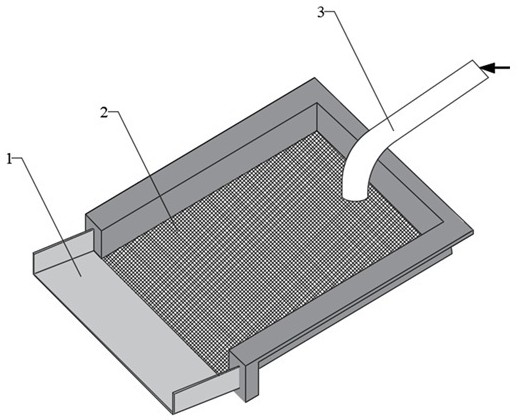

[0046] The sand and gravel separation module includes a vibrating screen, a screen and a gravel plate are arranged on the vibrating screen, and the sludge conveying pipe transports the sludge to the screen, and the mud seeps down through the gaps of the screen, and the sand that does not pass through the screen passes through the sieve. The above-mentioned gravel board enters the gravel collection bag;

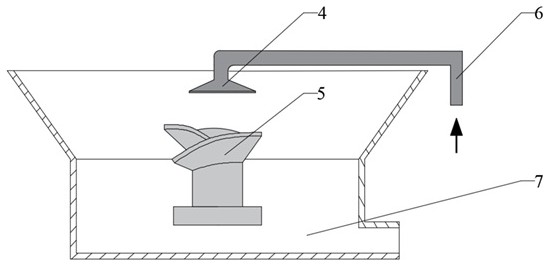

[0047] The liquid medicine mixing module includes a funnel, a liquid medicine mixing tank is arranged in the funnel, a stirring column is arranged in the liquid medicine mixing tank, a liquid medicine delivery pipe transports the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com