A bogie system of a rail vehicle and the rail vehicle

A rail vehicle and bogie technology, applied in the field of rail vehicles, can solve the problems of high noise and aerodynamic resistance of the bogie system, and achieve the effects of improving aerodynamic performance, reducing air resistance and reducing train far-field noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

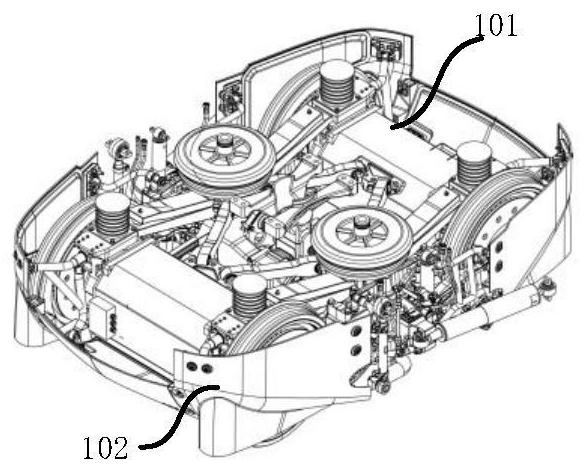

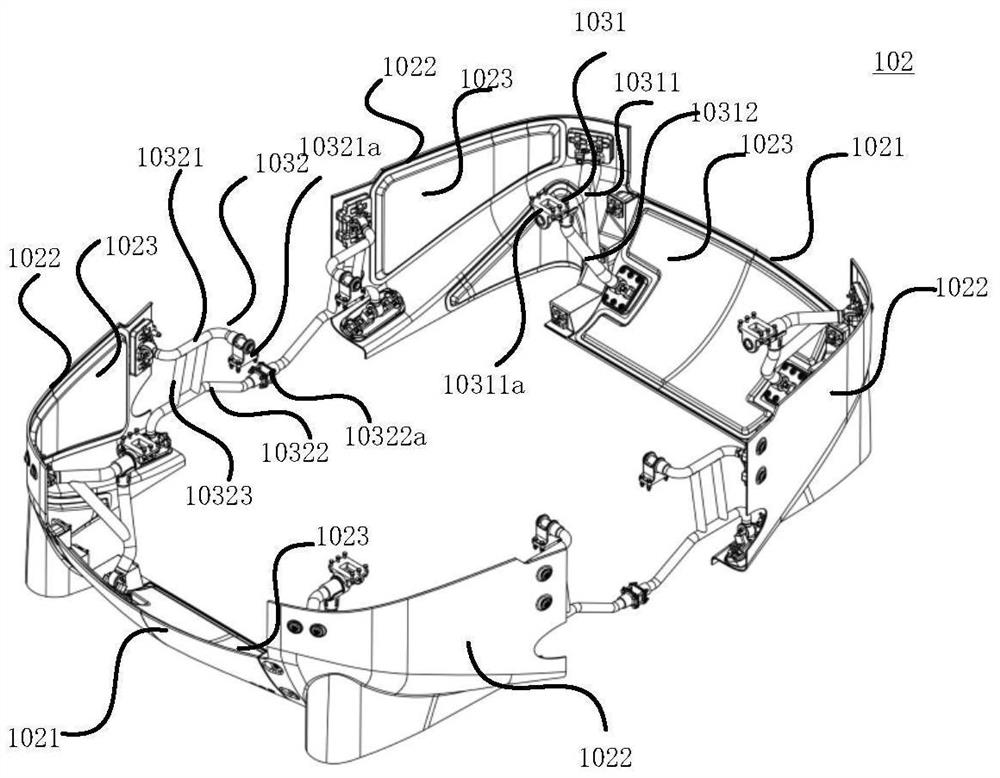

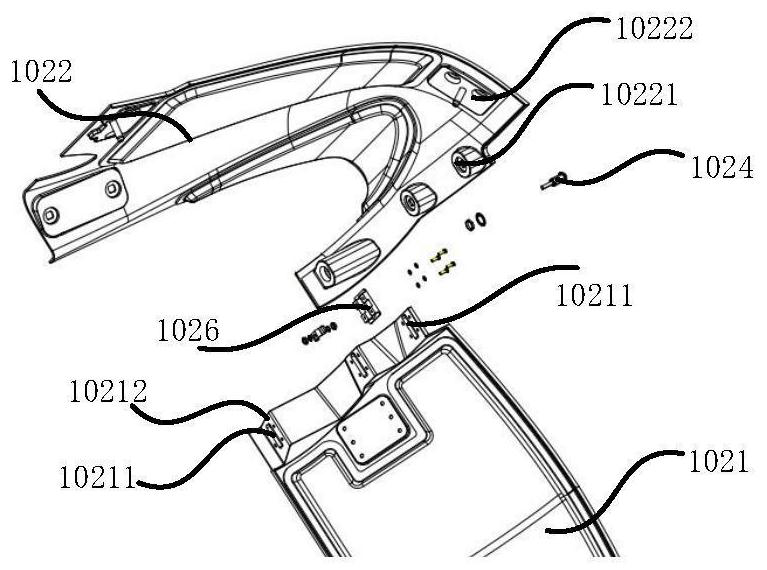

[0066] like figure 1 and figure 2 As shown, the bogie system of the rail vehicle in the embodiment of the present application includes a bogie 101 and a bogie cabin 102, and the bogie cabin includes a cabin assembly, and the cabin assembly includes:

[0067] main deck 1021;

[0068] Two side decks 1022, the two side decks 1022 are fixed on both sides of the main deck 1021, and enclose with the main deck 1021 a cavity for accommodating rail vehicle bogies;

[0069] Wherein, the inner side of the main deck is fixed to the front or rear of the bogie, separating the front or rear of the bogie from the outside world; the inner sides of the two side decks are fixed to the sides of the bogie to separate the bogie from the outside. The sides are separated from the outside world.

[0070] The bogie system of the rail vehicle in the embodiment of the present application includes a bogie and a bogie cabin, and the bogie cabin includes a cabin assembly. The cabin assembly includes a ...

Embodiment 2

[0170] On the basis of the bogie system in Embodiment 1, the bogie system of the embodiment of the present application has the following features.

[0171] The bogie of the bogie system of this embodiment also includes a crossbeam, and the bogie is suitable for rail vehicles, which can be diesel locomotives or electric locomotives, EMUs, subways, light rails or trams, etc., can be For passenger vehicles or freight vehicles.

[0172] In addition to the beam, the bogie also includes side beams, wheelsets, traction devices, suspension devices and other components.

[0173] In this embodiment, the horizontal direction that is the same as the traveling direction of the vehicle is called the longitudinal direction, the horizontal direction that is perpendicular to the longitudinal direction is called the horizontal direction, and the direction that is perpendicular to the horizontal direction is called the vertical or vertical direction. The beams extend transversely in the bogie. ...

specific Embodiment approach

[0179] The beam is made of cast aluminum alloy or other lightweight materials, and the cast mold can be made with additive manufacturing technology to reduce weight.

[0180] like Figure 17 As shown, the width of the end of the beam main body 21 facing the other beam monomer 2 is relatively large, which is greater than the width of the middle part of the beam main body 21 . The end face of the beam main body 21 facing the other beam monomer 2 is called the inner end face, and the first installation area and the second installation area are respectively located on the inner end face of the beam main body 21, specifically arranged at both ends along the width direction of the inner end face.

[0181] There is a certain distance between the first installation area and the second installation area, so that there is a certain gap between the two beam connecting arms 22 for accommodating the towing center pin in the bogie traction device. The top of the traction center pin is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com