Splicing device for small veneers

A splicing device, veneer technology, applied in the joining of wooden veneers, making finger joints, wood processing appliances, etc., can solve the problem of lack of quick cutting and splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

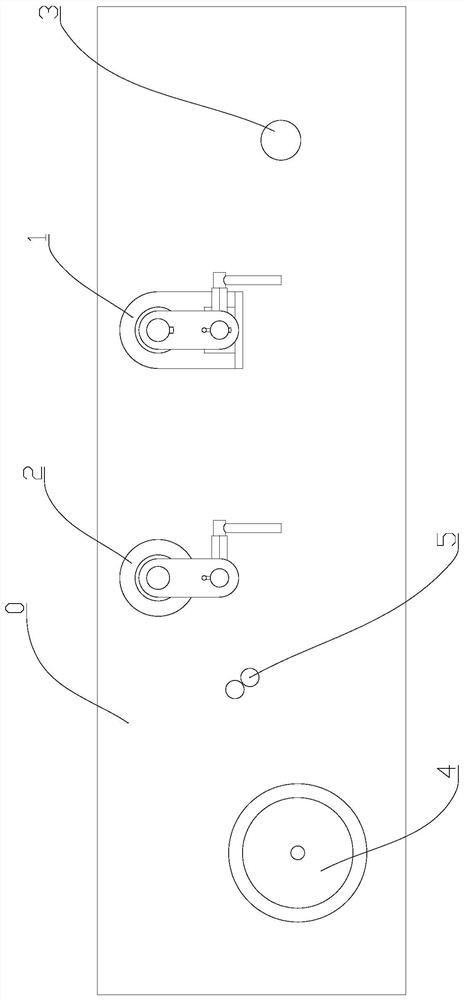

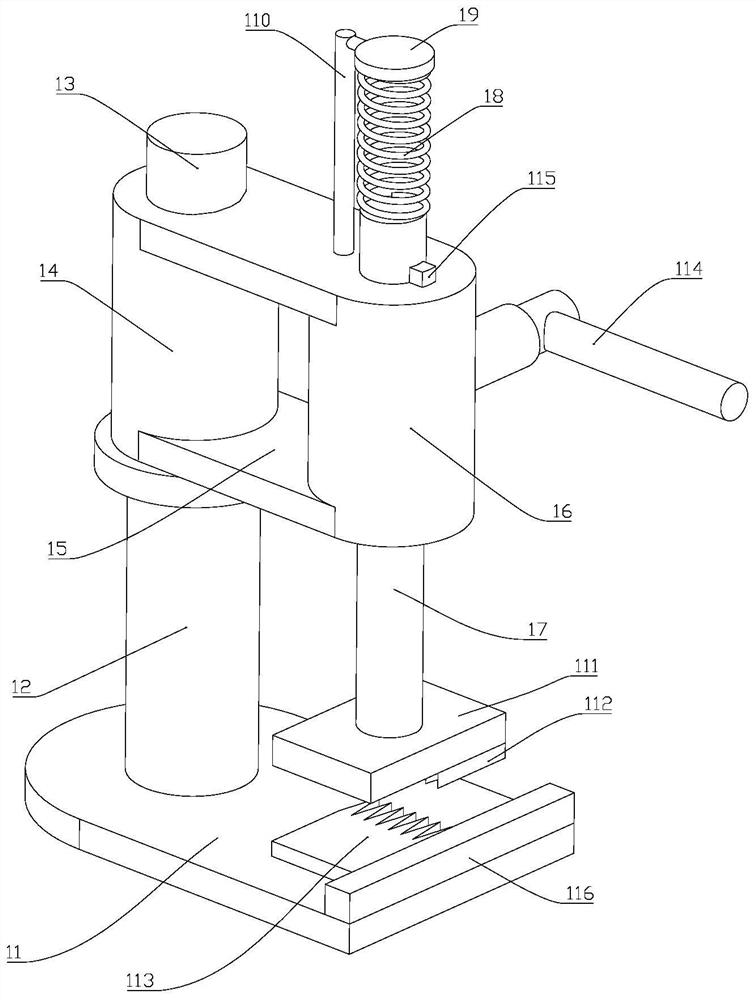

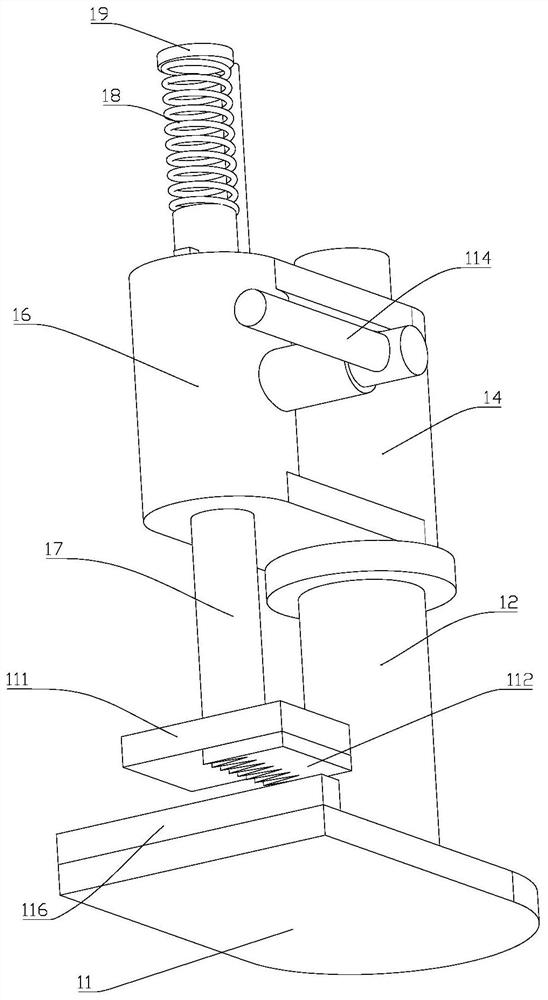

[0021] Such as Figure 1-5 As shown, a small veneer splicing device includes a splicing table 0, a front veneer roller shaft 3 vertically fixed on the splicing table 0, a rear veneer winding device 4, and a front veneer roller shaft 3 and a rear veneer winding The guide mechanism 5 of the device 4, the splicing table 0 is also provided with a cutting mechanism 1 and a pressing mechanism 2, the cutting mechanism 1 includes a cutting base 11, and a first support seat fixed on the cutting base 11 12. The top of the first supporting seat 12 is fixed with a first rotating shaft 13, and the first rotating shaft 13 is matched with a first rotating sleeve 14, and the first rotating sleeve 14 passes through the first connecting rod 15 is fixedly connected with the first sliding sleeve 16, the axes of the first rotating sleeve 14 and the first sliding sleeve 16 are parallel to each other, and the inside of the first sliding sleeve 16 is matched with a relative sliding connection The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com