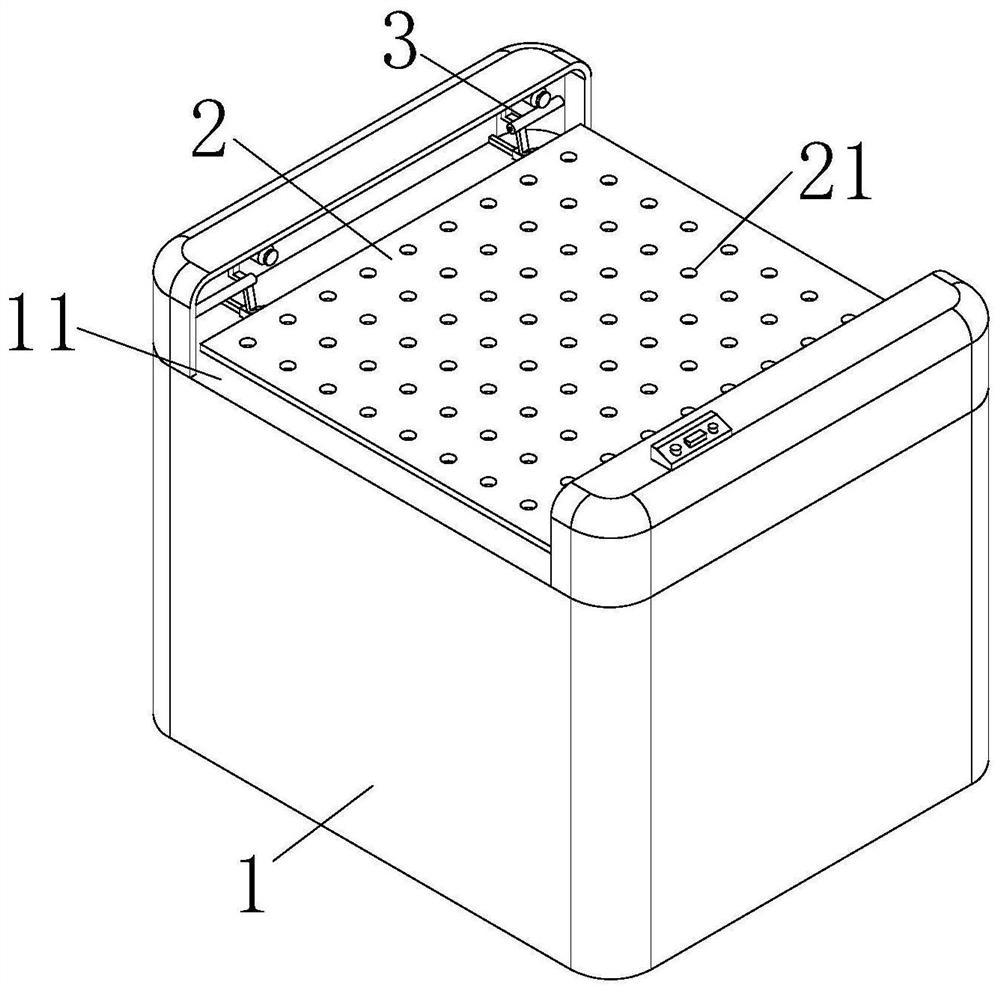

Auxiliary fabric supporting equipment for garment cutting machine

A technology for supporting equipment and cutting machines, applied in the field of clothing cutting, can solve problems such as fabric offset and wrinkles, and achieve the effects of avoiding waste, increasing stability and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

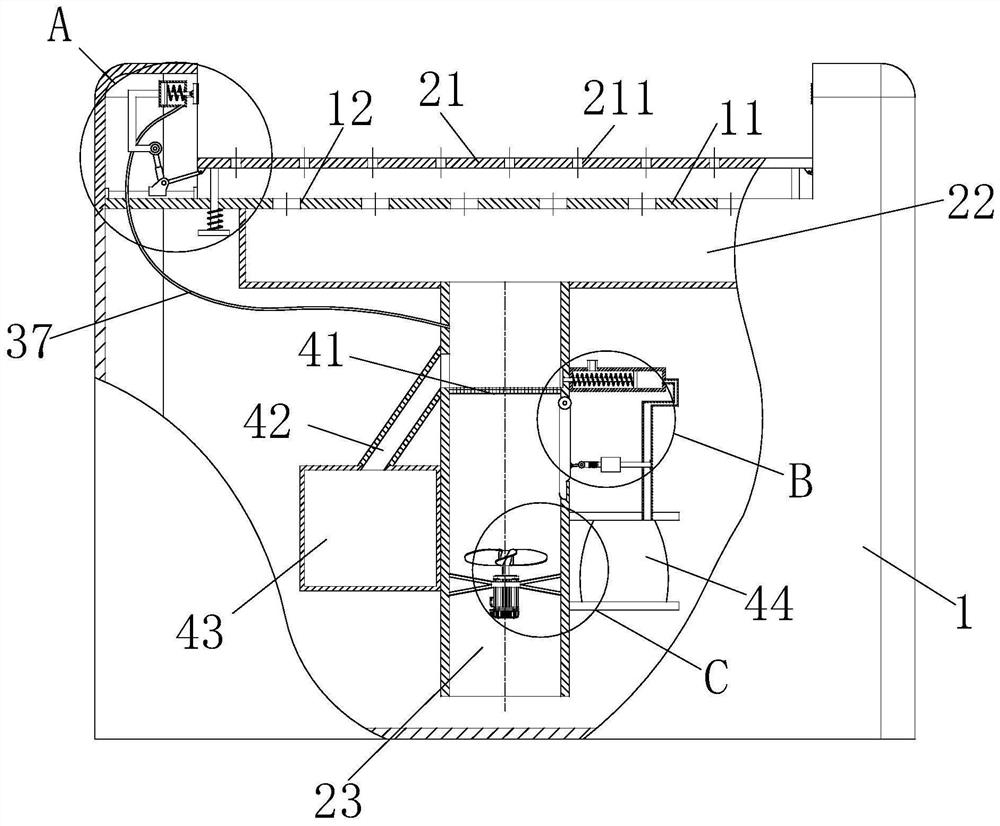

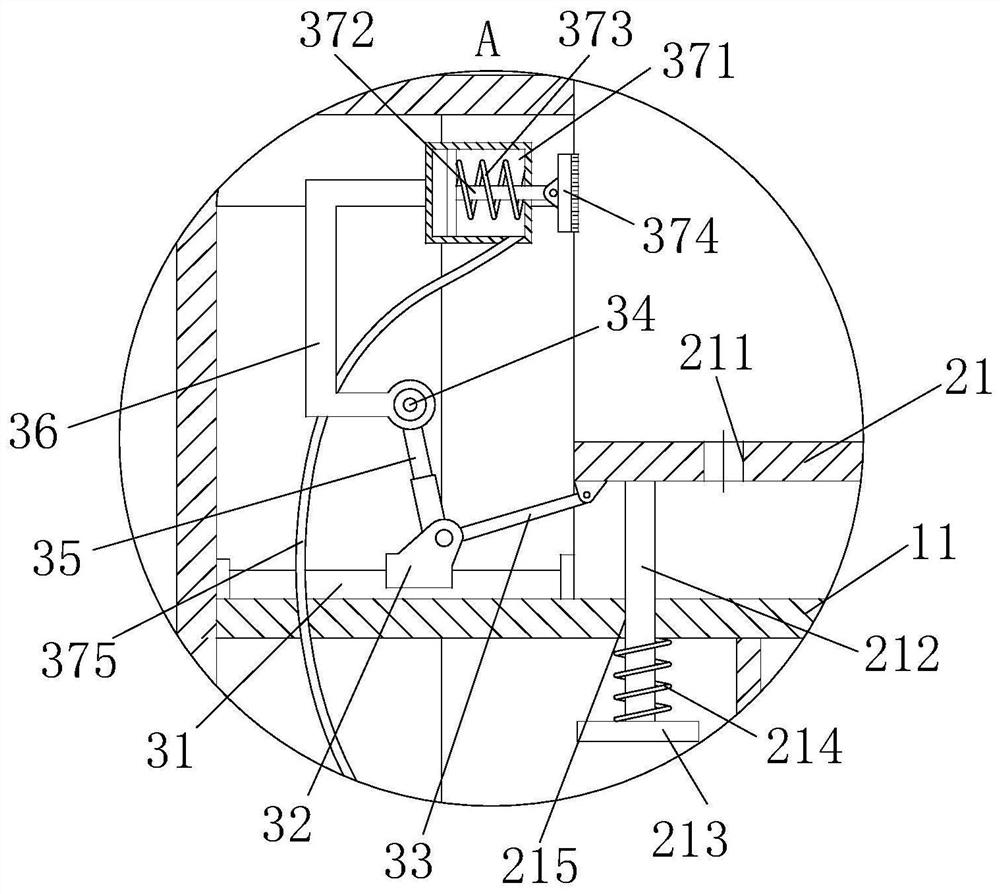

[0023]As an embodiment of the present invention, the fixing assembly 3 includes a chute 31, a slider 32, a pole 33, a fixed shaft 34, a telescopic rod 35, a pressing arm 36 and a pressing assembly 37; the chute 31 is fixed Connected to the top of the support plate 11; the slider 32 is slidably connected to the chute 31; one end of the pole 33 is hinged on the slider 32, and the other end is hinged on the side end of the support table 21; the fixed shaft 34 Fixed on the top inner wall of the workbench 1; the pressing arm 36 is rotatably connected to the fixed shaft 34; the bottom end of the telescopic rod 35 is hinged on the slider 32, and the top end is fixed on the bottom of the pressing arm 36; The pressing assembly 37 is arranged at the top side wall of the pressing arm 36; the air extraction assembly 5 includes a motor 51, a fan blade 52 and a bracket 53; the bracket 53 is fixed at the inner side wall of the air duct 23; The motor 51 is fixed inside the bracket 53; the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com